Air balance hydraulic pumping unit for offshore platform

An offshore platform and gas balance technology, which is applied in the fields of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of reducing installed power, eccentric wear of pistons, complex structure, etc., and achieve the reduction of machine weight and occupation The effect of reducing the floor area, reducing the height of the whole machine, and reducing the weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

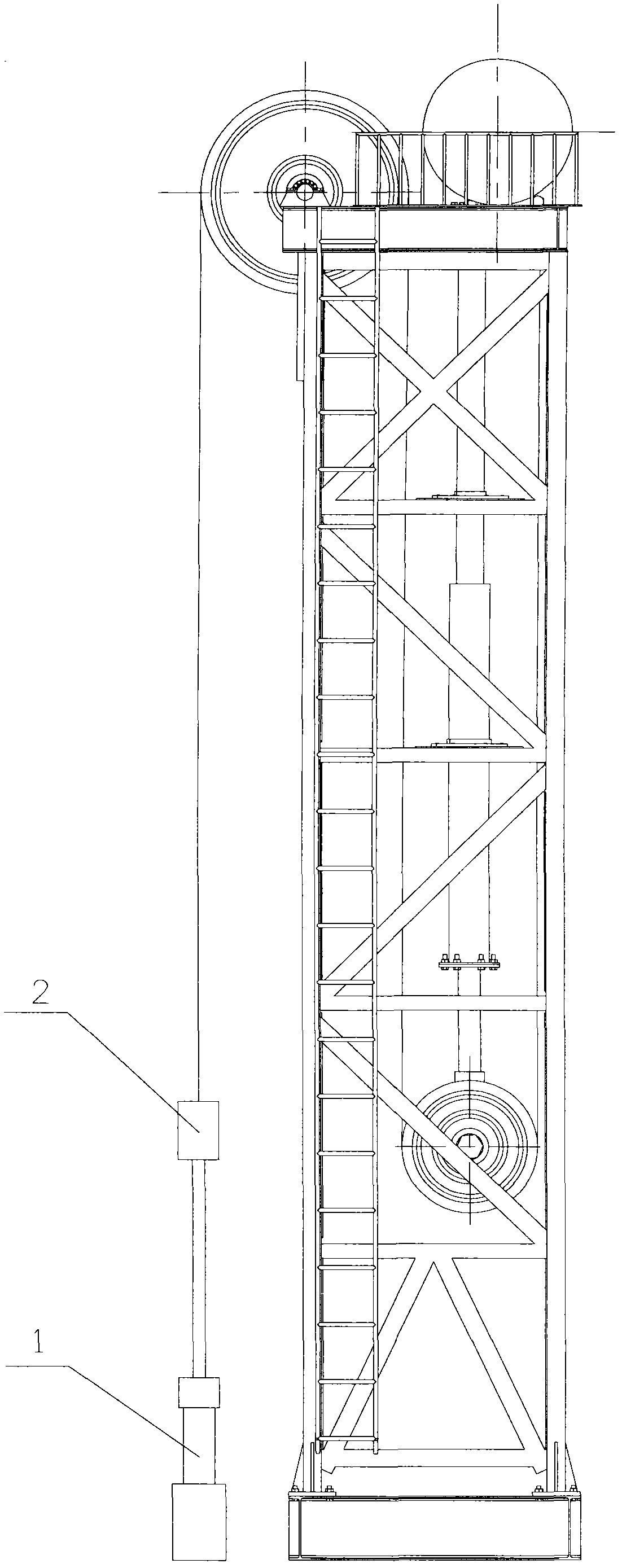

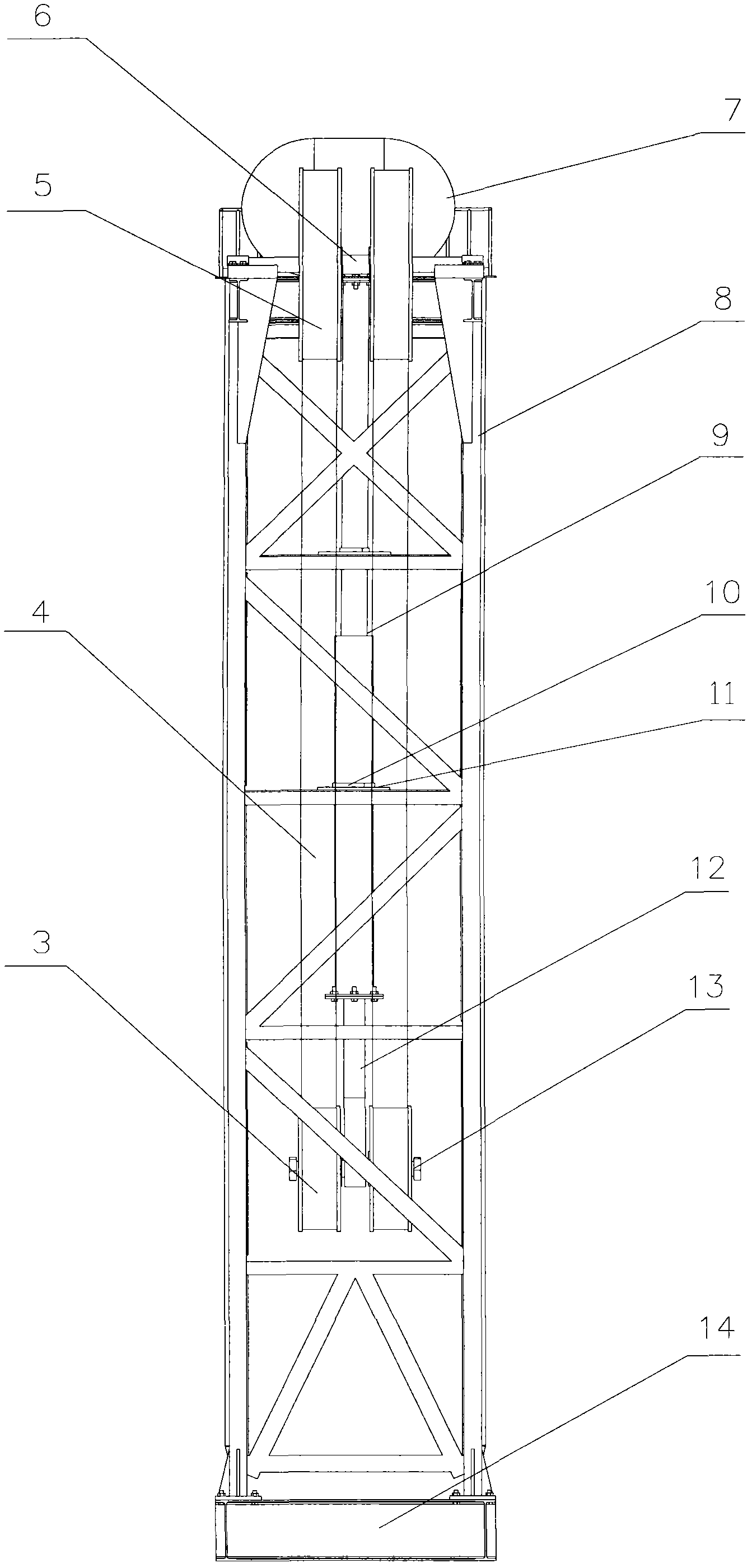

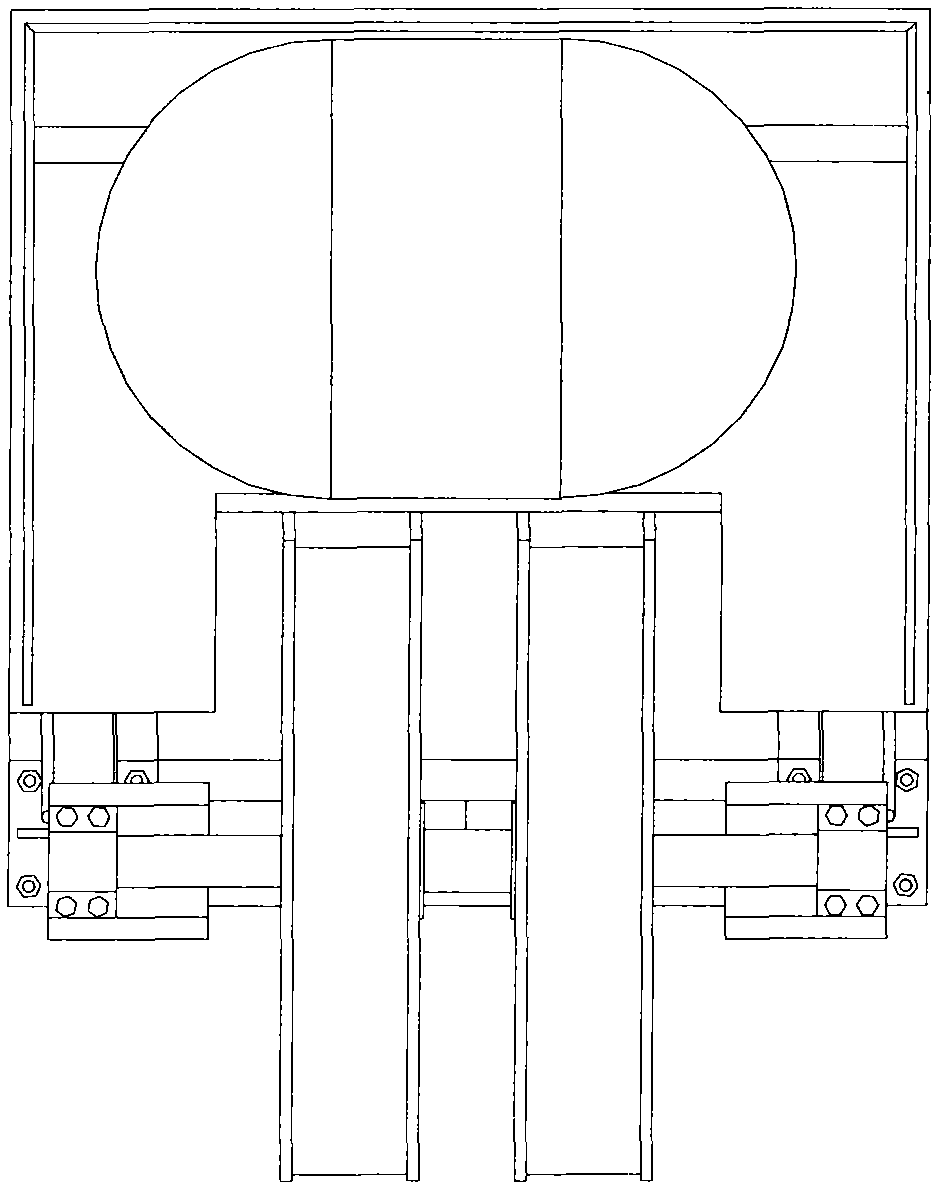

[0018] See attached figure 1 with figure 2 . The offshore platform uses an air-balanced hydraulic pumping unit, and the rope hanger 2 is connected to the sucker rod and the conveyor belt 4 of the oil production wellhead 1. The conveyor belt 4 belongs to one of the flexible connection mechanisms. The conveyor belt 4 walks around the fixed pulley 5 and the movable pulley 3, and the other end is fixed on the lifting lug at the lower end of the support top. The support 8 is 1000mm high and is welded by I-beams, angle steels and steel plates. The fixed pulley 5 is fixed on the fixed shaft 6, and the fixed shaft 6 is installed on the side of the support 8 close to the wellhead 1. The length of the fixed shaft 6 is equal to the width of the support 8. The accumulator 7 is fixed on the steel plate at the top of the support 8. The volume of the accumulator 7 is 1m 3 , the stepped composite hydraulic cylinder 9 is connected to the top of the bracket 8 by bolts, and on the side awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com