Defrosting method of three-pipe heating recovery system

A heat recovery, three-pipe technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of extremely high safety requirements, slow defrosting speed, large power consumption, etc., and achieve small heating effect. , Improve the comfort of use and the effect of high defrosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

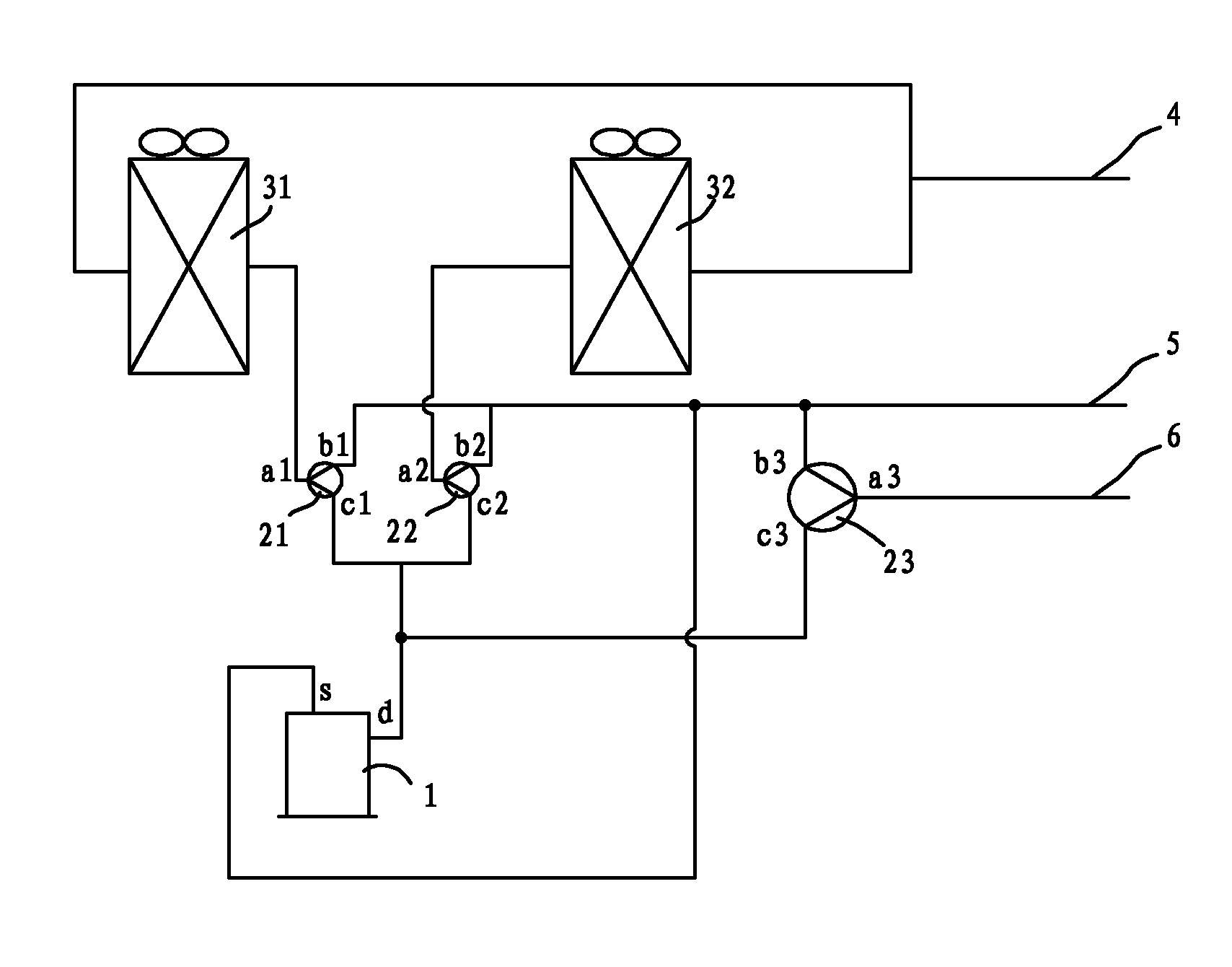

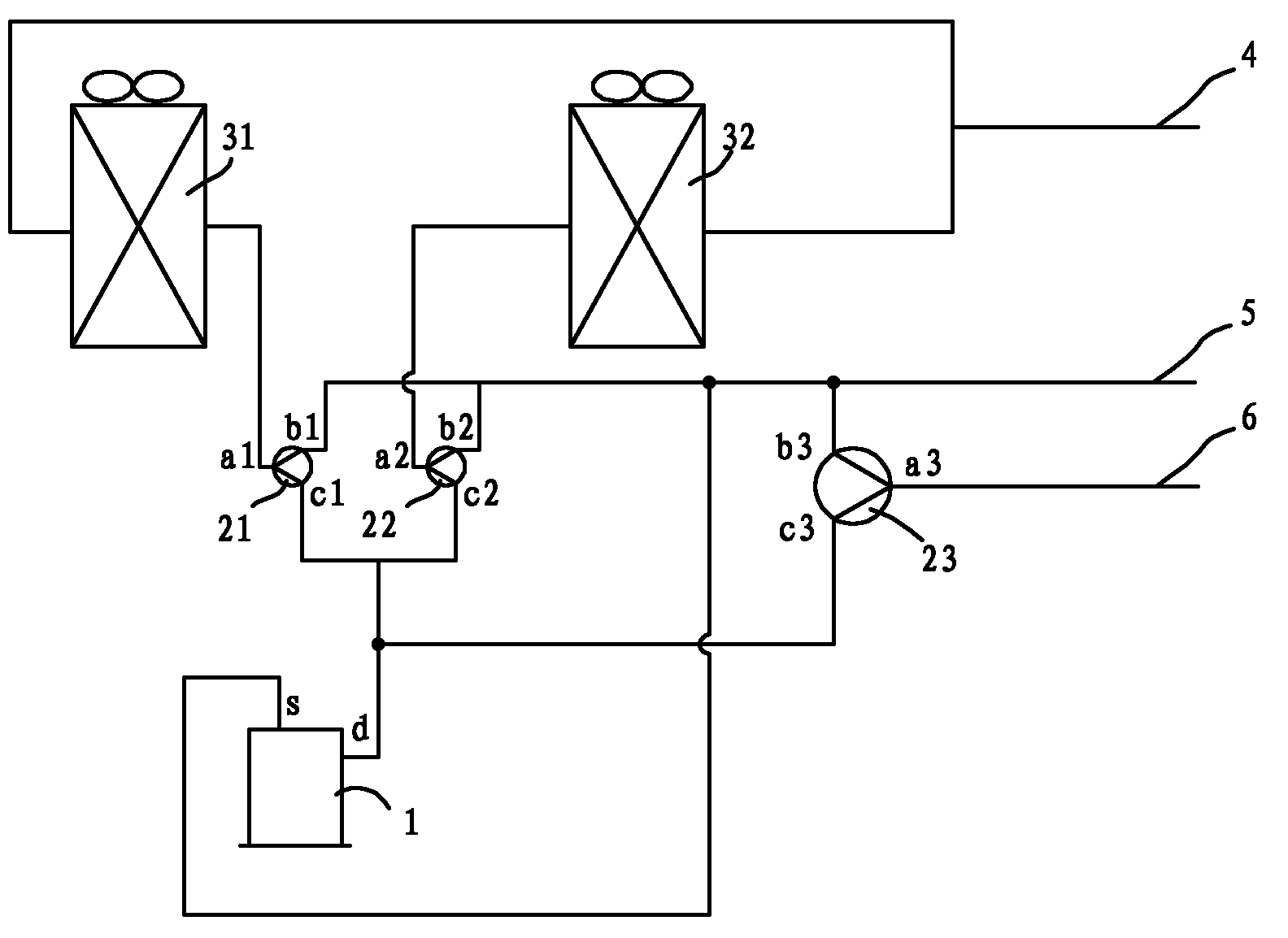

[0013] The defrosting method of the three-pipe heat recovery system, the outdoor unit of the three-pipe heat recovery system includes more than two outdoor heat exchangers, more than two three-way valves, more than one compressor, and high-pressure liquid pipes and low-pressure air pipes And the high-pressure air pipe, characterized in that in the heating mode or the mixed cooling and heating mode, when one of the outdoor heat exchangers is in the defrosting state of the condenser, the other outdoor heat exchanger must not be in the defrosting state of the condenser. During the defrosting process, the defrosting sequence of the outdoor heat exchanger can be adjusted arbitrarily according to the actual situation.

[0014] In heating mode or mixed cooling and heating mode, the outdoor heat exchanger is turned on successively and acts as a condenser for defrosting. The outdoor heat exchanger does not switch to condenser defrost at the same time. There is no limit to the number o...

no. 2 example

[0031] In this embodiment, the specific structure is the same as that of the first embodiment.

[0032] The following description will be made by taking defrosting as an example when both the first outdoor heat exchanger 31 and the second outdoor heat exchanger 32 are used as evaporators.

[0033] When the first outdoor heat exchanger 31 and the second outdoor heat exchanger 32 meet the set defrosting requirements, the first outdoor heat exchanger 31 first switches to condenser defrosting, and the second outdoor heat exchanger 32 maintains the original evaporation device status. After the first outdoor heat exchanger 31 completes the defrosting action, it switches back to the evaporator state, and at the same time, the second outdoor heat exchanger 32 switches to the condenser state for defrosting. After the second outdoor heat exchanger 32 completes the defrosting action , to switch back to the evaporator state. At this time, the two outdoor heat exchangers return to the or...

no. 3 example

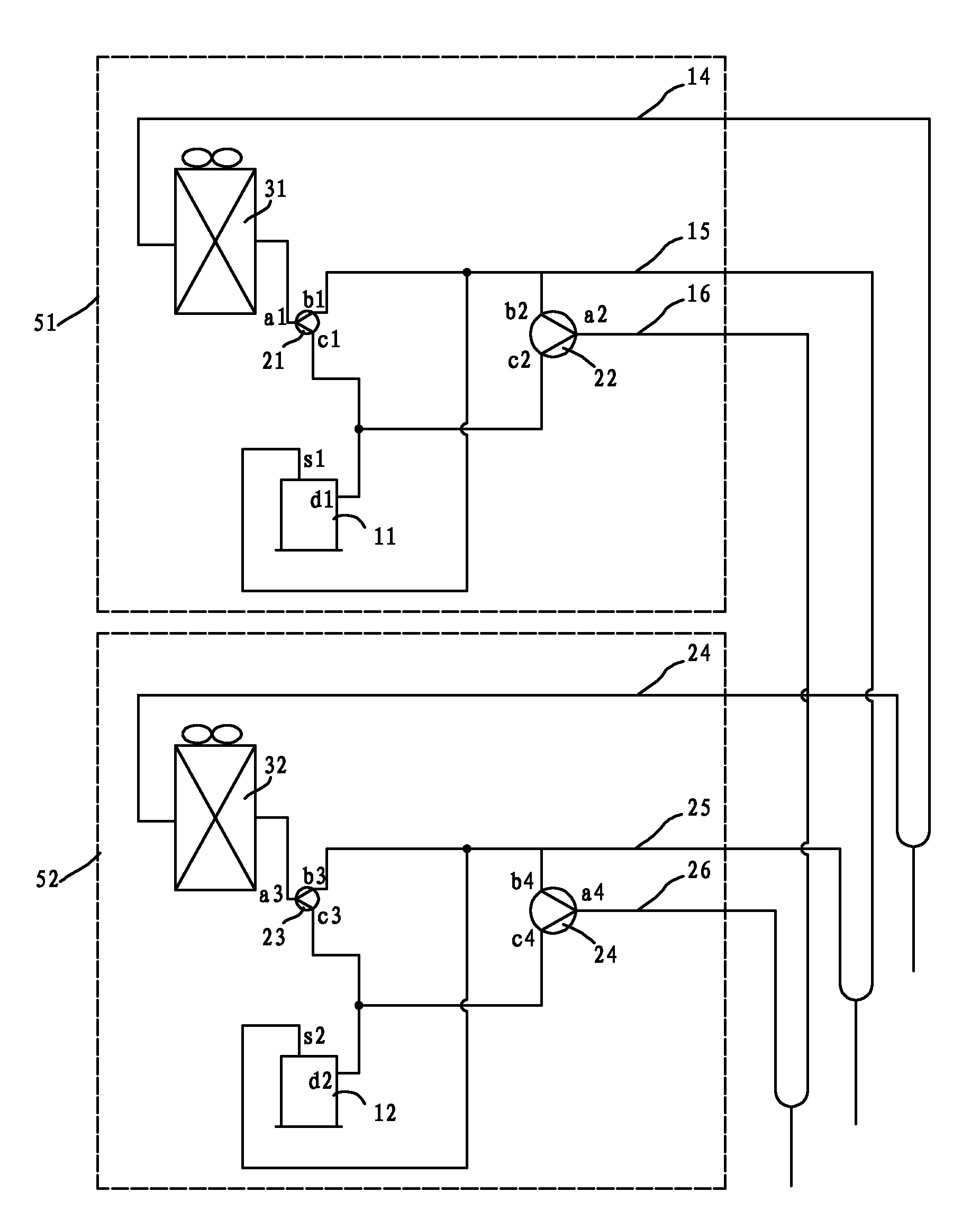

[0043] see figure 2 , the two-compressor structure of the three-pipe heat recovery system in this embodiment, the first outdoor unit 51 includes a first compressor 11, a first three-way valve 21, a second three-way valve 22, a first outdoor heat exchanger 31. The first high-pressure liquid pipe 14 , the first low-pressure air pipe 15 and the first high-pressure air pipe 16 .

[0044] The first discharge pipe d1 of the first compressor 11 is respectively connected to the third port c1 of the first three-way valve 21 and the third port c2 of the second three-way valve 22 .

[0045]The second port b1 of the first three-way valve 21 and the second port b2 of the second three-way valve 22 are respectively connected to the first low-pressure air pipe 15 and connected to the first air return pipe s1 of the first compressor 11 .

[0046] One end of the first outdoor heat exchanger 31 is connected to the first interface a1 of the first three-way valve 21 , and the other end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com