Steam turbine single-valve adjusting valve

A technology for regulating valves and steam turbines, applied to mechanical equipment, engine components, machines/engines, etc., can solve problems such as unstable load speed, difficult adjustment of overlap, and errors, so as to prevent water accumulation and water erosion, eliminate instability, Reduce the effect of instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

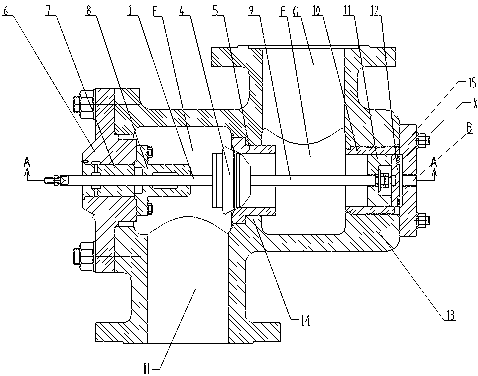

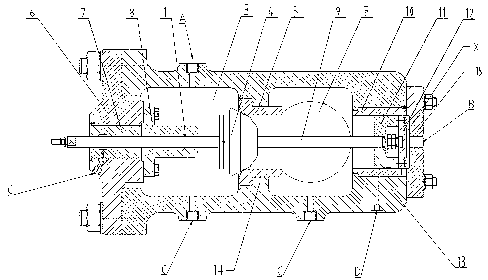

[0048] Examples such as figure 2 , image 3 As shown, a steam turbine single-valve regulating valve includes a valve housing 13;

[0049] There is a chamber in the valve housing 13, and a partition 14 is arranged in the chamber, and the partition 14 divides the chamber into a first chamber E and a second chamber F;

[0050] The valve casing 13 is provided with a steam inlet H communicated with the first chamber E and a steam outlet G communicated with the second chamber F;

[0051] A regulating valve cover 6 is provided on the valve housing 13 close to the first chamber E, and the regulating valve cover 6 is fixed to the valve housing 13 by bolts;

[0052] A valve seat 5 is provided on the partition 14, and a valve disc 4 is installed in the valve seat 5;

[0053] One end of the valve disc 4 is connected to the regulating valve stem 1, and the other end is connected to a balance device;

[0054] The other end of the regulating valve rod 1 is slidably connected with the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com