High-pressure liquid supplying displayable distributor

A distributor and liquid supply technology, applied in liquid distribution, gas/liquid distribution and storage, distribution devices, etc., can solve the problems of adjusting the amount of lubricating fluid in parts that cannot be lubricated, and adjusting separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

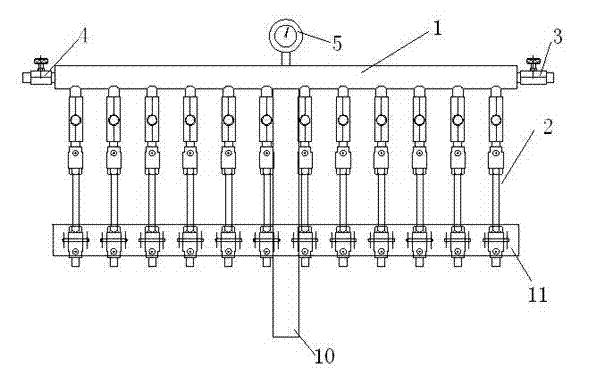

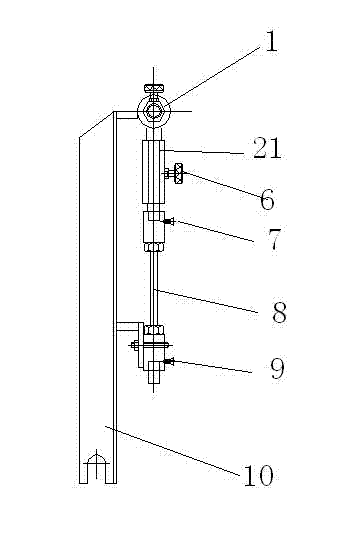

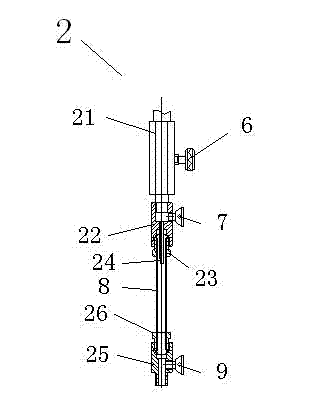

[0020] Such as figure 1 , 2 , 3, the high-pressure liquid supply disclosed in the present invention can display the distributor, including: main liquid pipe 1, several liquid pipes 2, liquid inlet valve 3, overflow valve 4, pressure gauge 5, control valve 6 and Fixed bracket. One end of the main liquid pipe 1 is provided with a liquid inlet valve 3 for connecting with a high-pressure liquid pump. The other end is provided with an overflow valve 4, and the overflow valve 4 is used for pressure relief when the pressure in the main liquid pipe 1 is too high. A number of dispensing pipes 2 are uniformly distributed along the axis of the main liquid pipe 1, and are in liquid communication with the main liquid pipe. Each dispensing pipe 2 is provided with a regulating valve 6 for regulating the flow of the main liquid pipe 1. The amount of liquid into each liquid pipe 2; the fixed bracket is used to support the main liquid pipe 1 and the fixed liquid pipe 2. Such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com