Air intake/evacuation valve for electric cooking appliance

A technology of intake and exhaust valves and electric cooking utensils, which can be used in household utensils, kitchen utensils, and cooking utensil lids, etc., and can solve problems such as difficulty in closing lids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

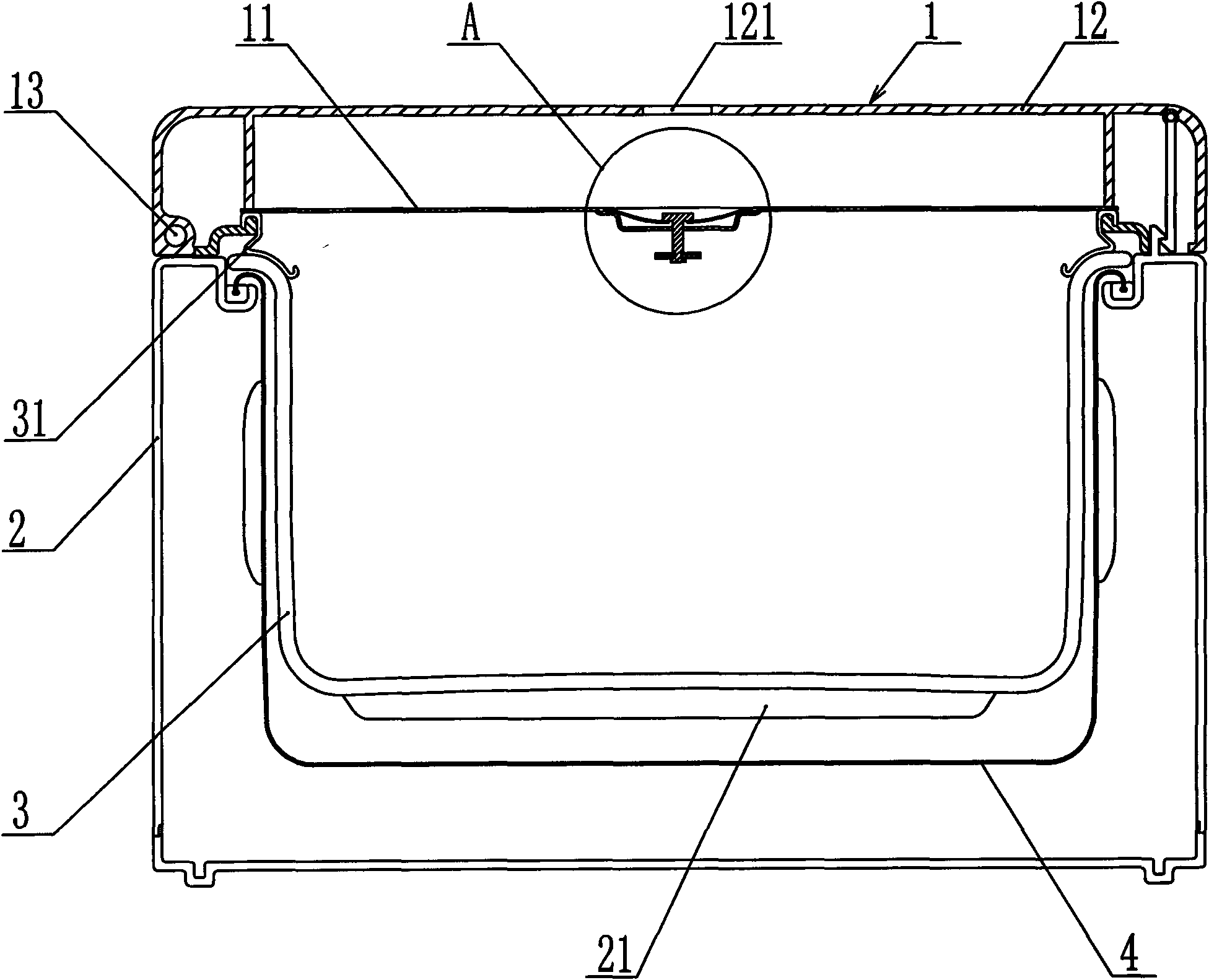

[0026] Such as figure 1 , figure 2 and image 3 Shown, a kind of electric cooker, comprises pot lid 1, pot body 2, inner pot 3 and heater 21, and wherein said pot body 2 is the main carrying part of described electric cooker, and inner pot 3, heater are arranged in it 21. The outer pot 4 and the electric control system of the electric cooker, the pot cover 1 is located on the upper part of the pot body 2 and an inner pot sealing ring 31 is arranged between the inner pot 3 and the outer pot 4 .

[0027] The pot cover 1 includes an outer shell 12 and an inner cover 11 , and the pot cover 1 is hingedly connected by a hinge device 13 provided between the outer shell 12 and the pot body 2 so that it can be flipped. The inner pot 3 is arranged in the pot body 2, and a heater 21 is arranged on the periphery of the inner pot 3, and the heater 21 is electrically connected with the control system of the micro-pressure cooker.

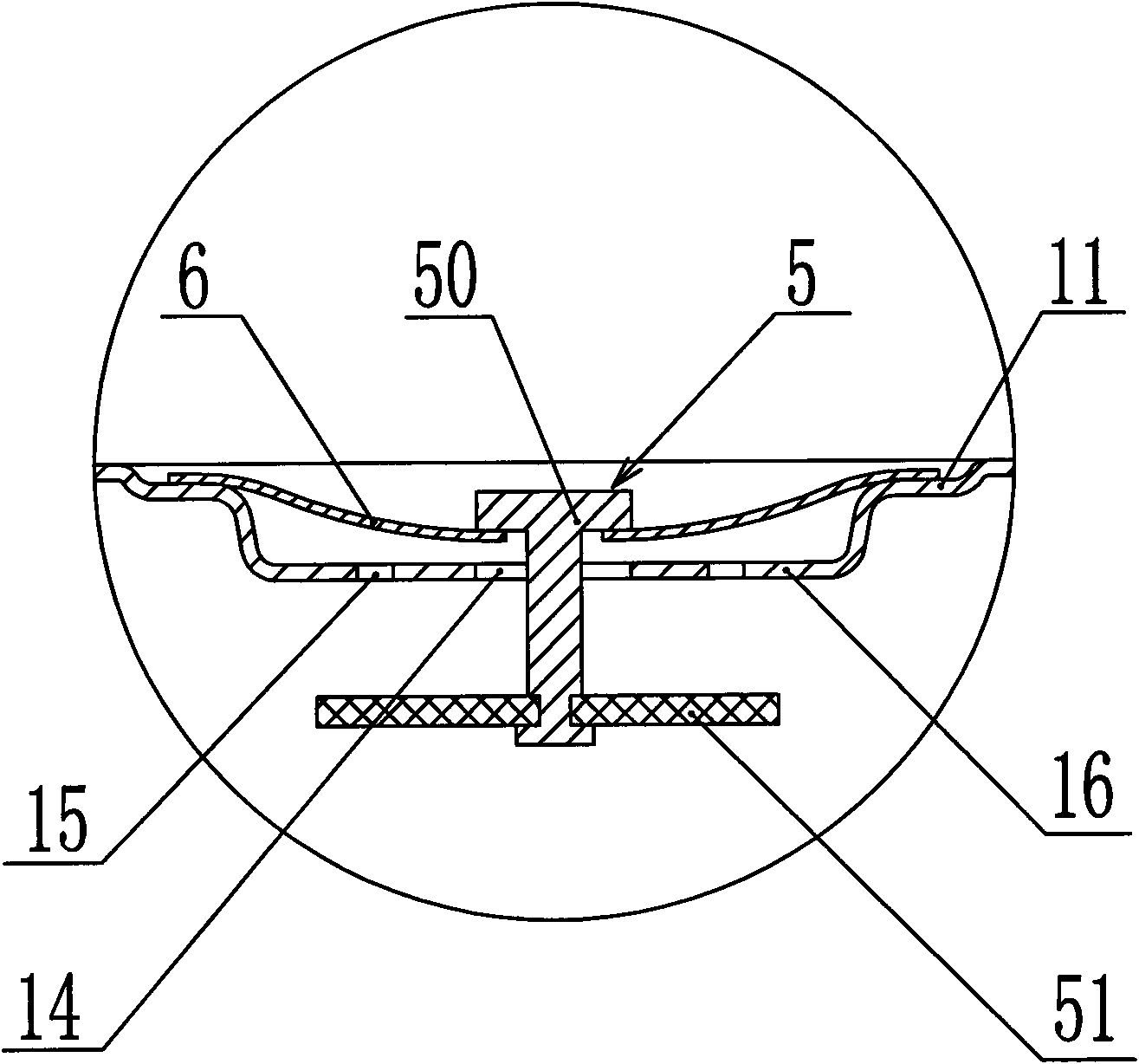

[0028] A pit 16 is set on the inner cover 11 , and an a...

Embodiment 2

[0035] Such as Figure 4 As shown, the difference from the first embodiment is that the valve core 5 is an inverted T-shaped soft plug 7 made of silicone rubber. The cushion block 8 is fixedly connected under the inner cover 11 . The upper part of the soft plug 7 protrudes into the air intake hole 14 , and the outer diameter of the upper part of the soft plug 7 is smaller than the inner diameter of the air intake hole 14 . In this way, when the temperature in the pot exceeds a certain value and the bimetal 6 also senses the corresponding temperature, the bimetal 6 deforms and pushes the soft plug 7 to move upward, and the protruding edge at the bottom of the soft plug 7 is closed The intake and exhaust holes 14 enable the pressure in the inner pot 3 to start to accumulate. When cooking finishes or uncovers pot cover 1 in the process of cooking, because pot cover 1 itself is in the air, described bimetal sheet 6 is cooled rapidly so that it resets to Figure 4 In the state s...

Embodiment 3

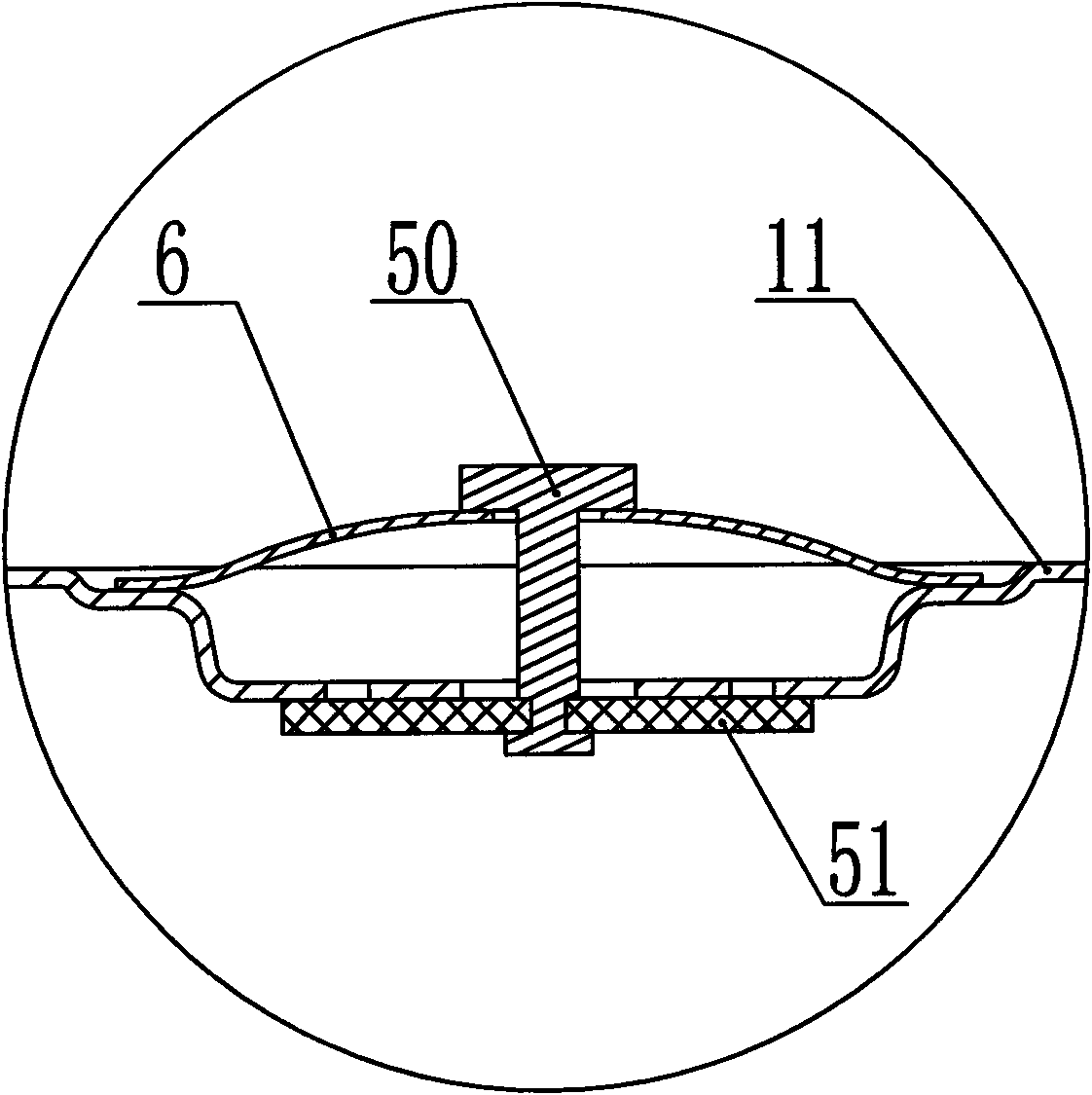

[0037] Such as Figure 5 As shown, it is a structural schematic diagram of the third embodiment applying the technical solution of the present invention. The difference from the first embodiment is that a housing 9 is provided on the inner cover 11 , and the housing 9 is set in the hole of the inner cover 11 by thread or embedding. An isolation platform 17 is arranged inside the housing, and the center of the isolation platform 17 is provided with the intake and exhaust holes 14 and the auxiliary intake and exhaust holes 15, and the bimetal 6 is erected on the isolation platform 17 And the middle part thereof is connected to the upper part of the "T" shaped rod part 50 of the valve core 5, and the lower part of the rod part 50 is provided with a sealing member 51. The inner diameter of the inlet and outlet holes 14 is larger than the outer diameter of the shaft portion 50 so that there is a gap therebetween. When the bimetal 6 is heated and deformed, it can drag the sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com