A kind of formation method of polymer lithium ion battery

A technology of lithium ion battery and formation method, applied in the field of polymer lithium ion battery manufacturing, can solve the problems such as displacement of the electrode winding core and aluminum plastic film of the battery, shortening of the formation voltage and formation time, and the battery cannot be loaded into the mobile phone compartment, etc. To achieve the effect of no hidden quality problems, good hardness, and low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

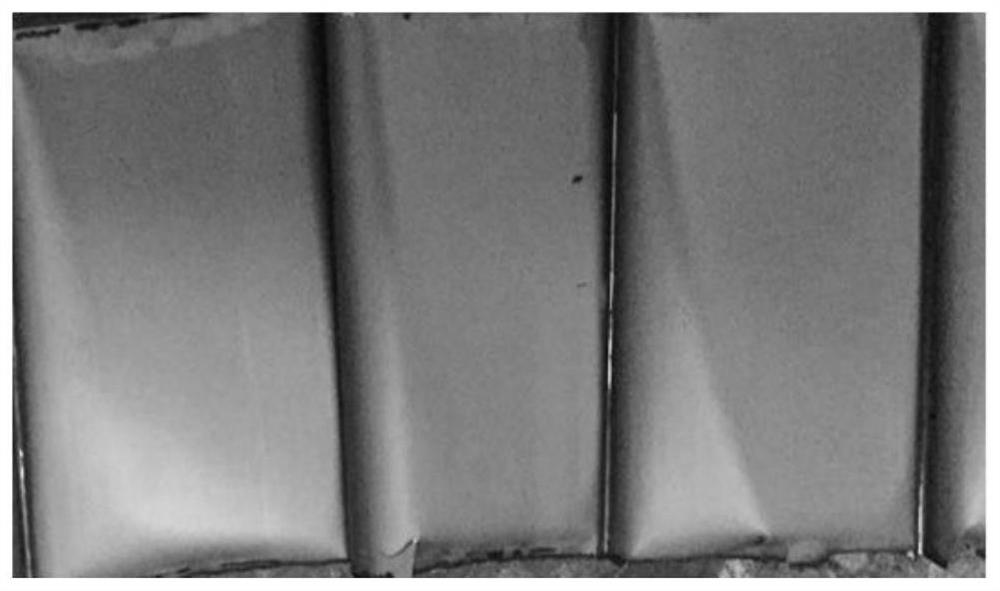

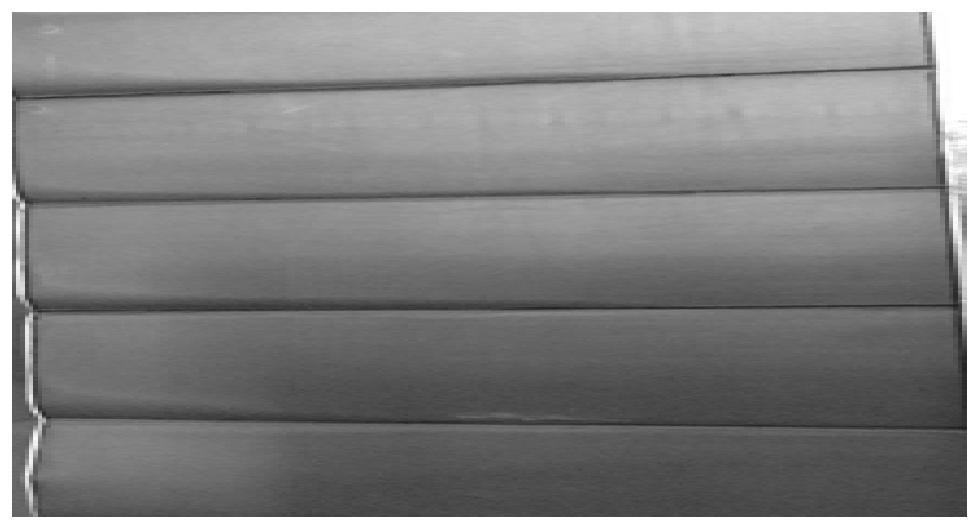

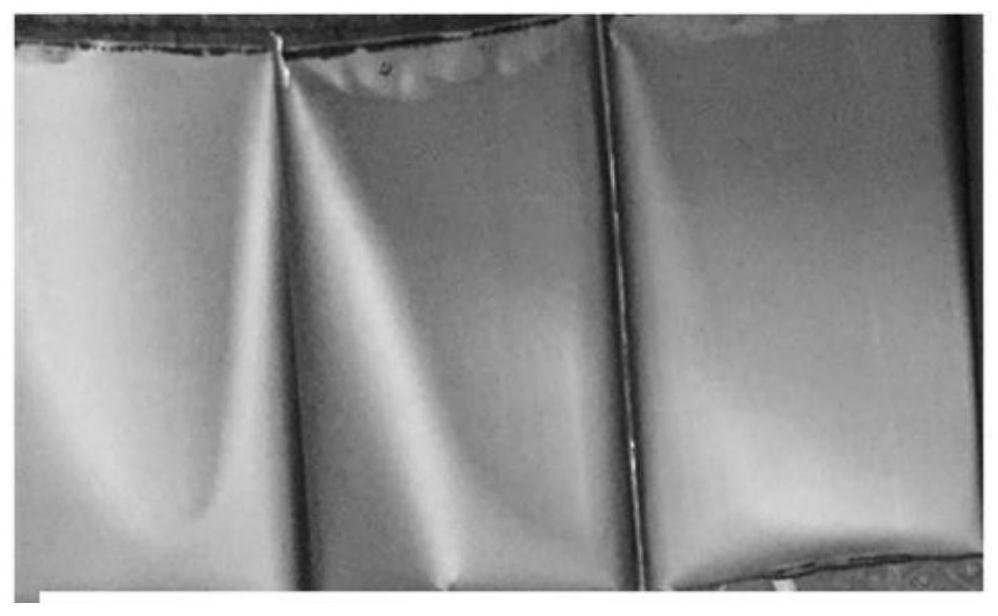

Image

Examples

Embodiment 1

[0048] 356290PL300FY 4.4V battery high temperature formation process

[0049] (1) After vacuumizing the battery liquid injection, after aging at a high temperature of 50±5°C for 24 hours, put the battery on the pressure forming cabinet;

[0050] (2) After the temperature of the pressure forming cabinet reaches the set temperature of 50°C, the battery is compressed, the layer spacing of the pressure forming cabinet is reduced, the closing speed between the layers is 0.5cm / s, and the closing pressure is 0.50kg / cm 2 , closing time is 10min.

[0051] (3) Send parameter formation, use 2 stages of step charging and 3 stage discharge, and use 4 stages of different pressures, the specific formation pressure and formation parameter settings are shown in Table 1-1 and 1-2.

[0052] (4) After the pressure is turned into pressure, immediately remove the battery and put it in a low temperature environment of 0°C for rapid cooling for 3 hours;

[0053] (5) Vacuumize and seal the battery a...

Embodiment 2

[0060] 356290PL300FY 4.4V battery high temperature formation process

[0061] (1) After vacuuming the injection liquid, after aging at a high temperature of 85°C±5°C for 4h, put the cell on the pressure forming cabinet;

[0062] (2) After the temperature of the pressure forming cabinet reaches the set temperature of 70°C, the battery is compressed, the layer spacing of the pressure forming cabinet is reduced, the closing speed between the layers is 0.5cm / s, and the closing pressure is 0.50kg / cm 2 , closing time is 10min.

[0063] (3) Send parameter formation, use 2 stages of step charging and 3 stage discharge, and use 4 stages of different pressures, the specific formation pressure and formation parameter settings are shown in Table 2-1 and 2-2.

[0064] (4) Immediately after the pressure forming is completed, remove the battery and place it in a low temperature environment of 0°C for rapid cooling for 3 hours;

[0065] (5) Vacuum seal the battery after cooling, and the ele...

Embodiment 3

[0072] 356290PL300FY 4.4V battery high temperature formation process

[0073] (1) After vacuuming the injection liquid, after aging at a high temperature of 50°C±5°C for 4h, put the cell on the pressure forming cabinet;

[0074] (2) After the temperature of the pressure forming cabinet reaches the set temperature of 70°C, the battery is compressed, the layer spacing of the pressure forming cabinet is reduced, the closing speed between the layers is 0.5cm / s, and the closing pressure is 0.50kg / cm 2 , closing time is 10min. .

[0075] (3) Send parameter formation, use 2 stages of step charging and 3 stage discharge, and use 4 stages of different pressures, the specific formation pressure and formation parameter settings are shown in Table 3-1 and 3-2.

[0076] (4) Immediately after the pressure forming is completed, remove the battery and place it in a low temperature environment of 0°C for rapid cooling for 3 hours;

[0077] (5) Vacuum seal the battery after cooling, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com