High speed braiding machine

A high-speed knitting machine and reducer technology, applied in the direction of knitting, textiles and papermaking, etc., can solve the problems of many product threads, unreasonable structure, and frequent shutdowns, etc., and achieve reasonable appearance design, complete internal structure, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

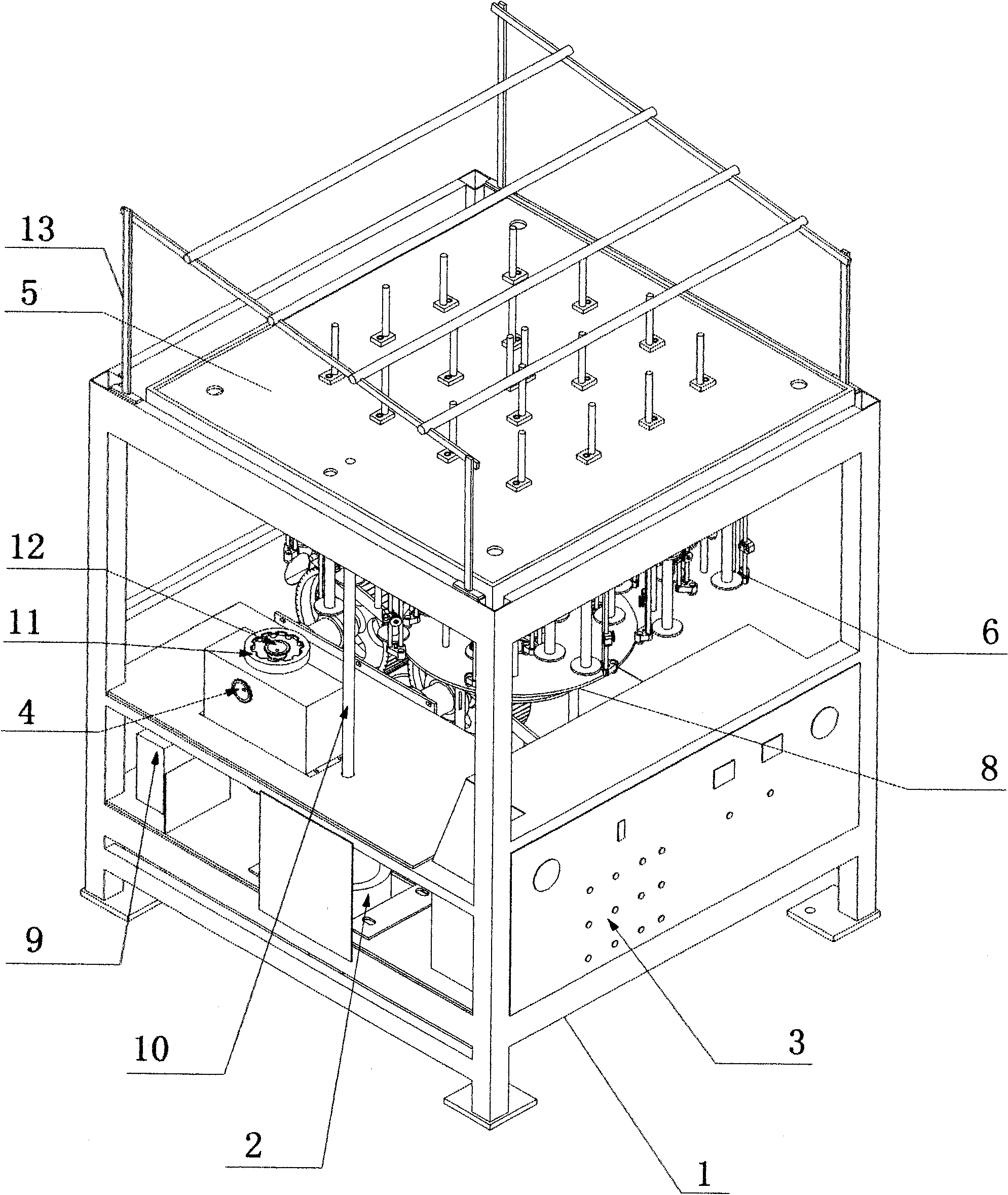

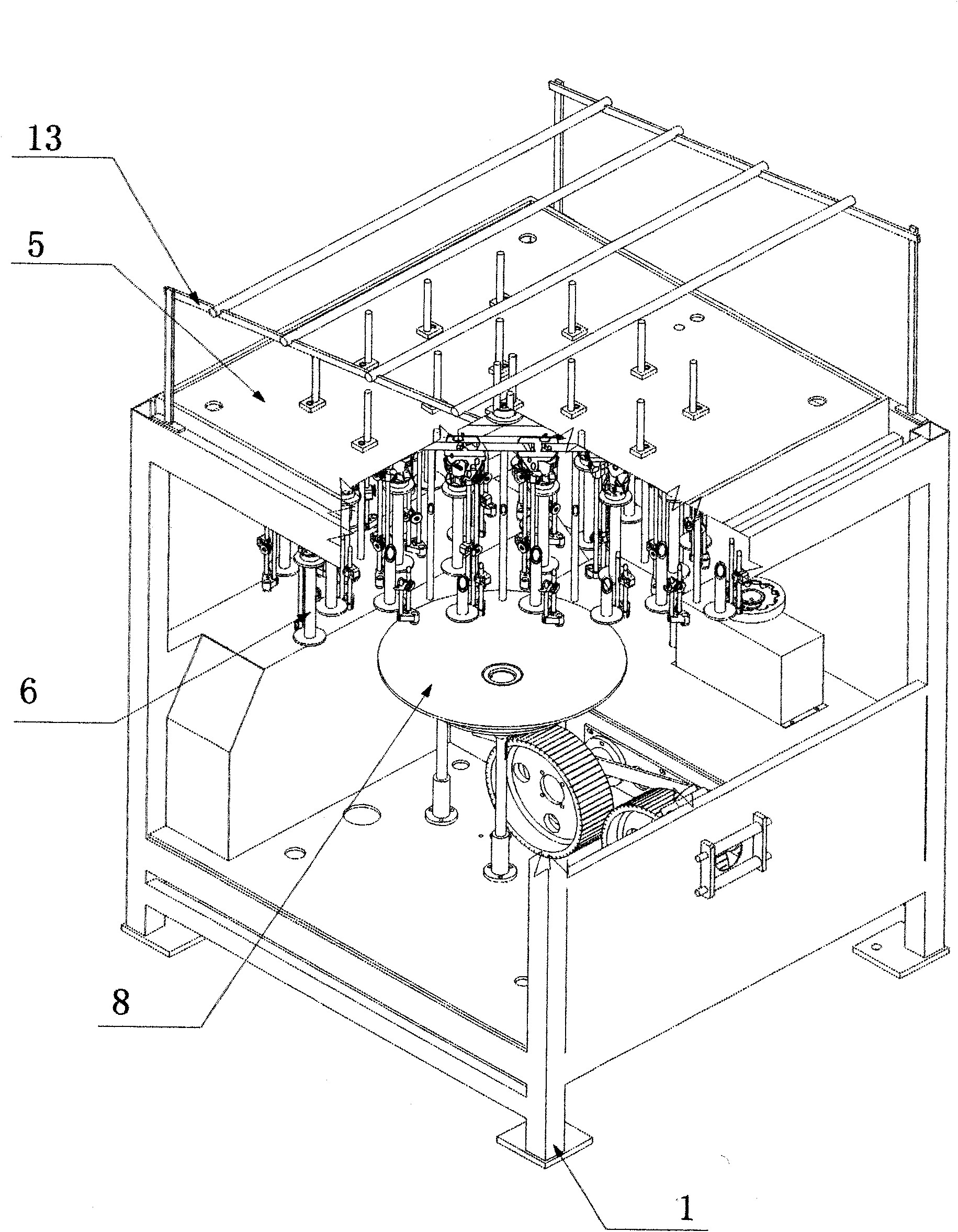

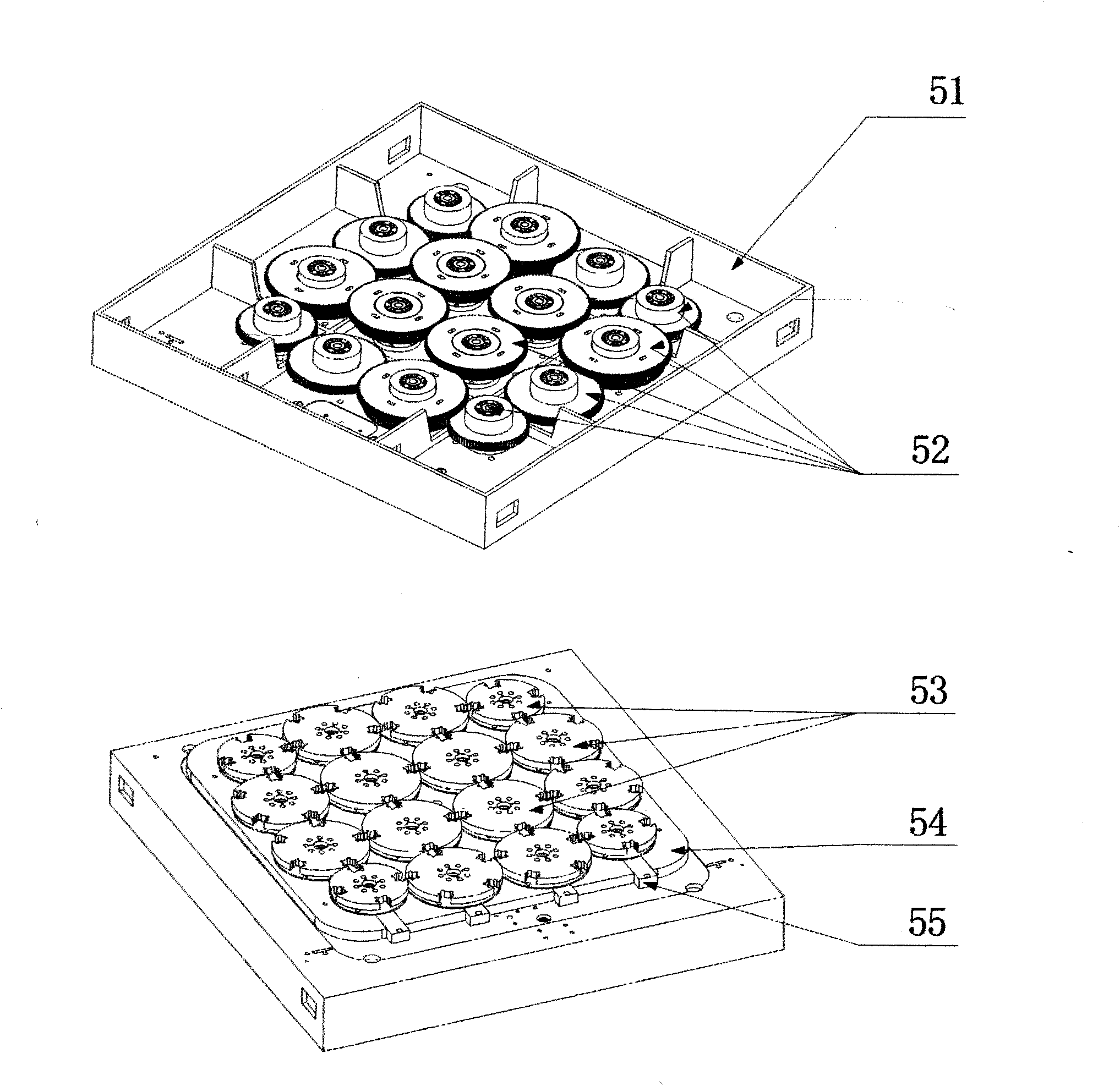

[0032] A high-speed knitting machine of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] as attached Figure 1-5 As shown, a high-speed knitting machine includes a frame 1, the bottom of the frame 1 is provided with a main motor 2 and an operation panel 3 connected to the main motor 2, and the main motor 2 is connected and set by pulling out a reducer 4 On the platen track gear part 5 on the top of the frame 1, the spindle part 6 is connected below the platen track gear part 5, and the bottom of the frame 1 is also provided with a heating plate 8 connected by a lifting part 7, The lifting part 7 is connected to a lifting motor 9 arranged at the bottom of the frame 1 .

[0034] The pull-out reducer 4 is connected to the platen track gear part 5 through a transmission part 10 .

[0035] A pull-out handwheel 11 and a disengagement handwheel 12 are arranged in the pull-out reducer 4 .

[0036]...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap