Method for dyeing and finishing nylon spandex knitted fabrics

A knitted fabric, nylon spandex technology, applied in the field of fabric dyeing and finishing, can solve the problems of uneven scratching, narrow application area, limited application scope, etc., and achieve the effect of good vertical sense, extended application scope, and rich three-dimensional texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

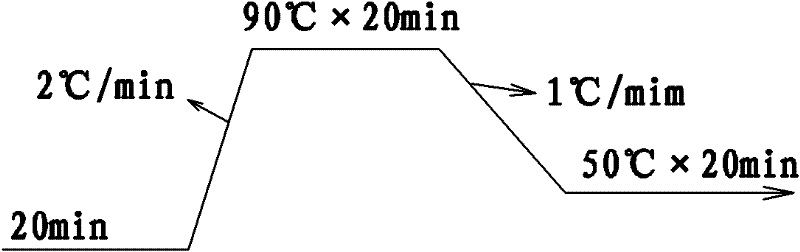

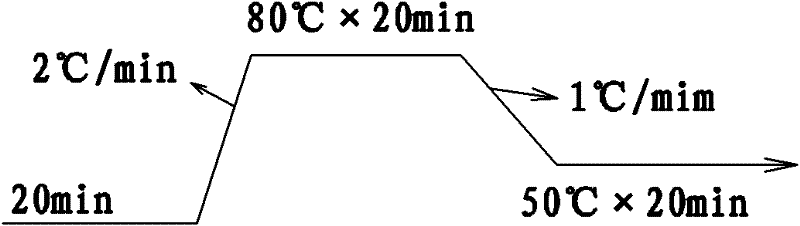

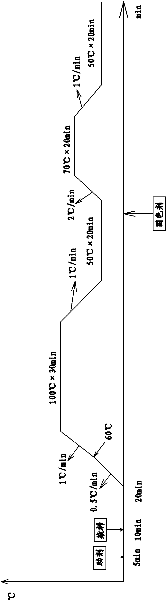

[0016] The dyeing and finishing method of nylon and spandex knitted fabrics of the present invention is mainly realized through the following steps in sequence: pretreatment step A, blank setting step B, dyeing step C and finished product forming step D. In the following, for the convenience of description, nylon spandex knitted fabric is called gray cloth.

[0017] A. Preprocessing steps

[0018] Arrange the blanks in Taiwan Huashan washing machine, and carry out continuous open-width washing in 1 to 6 boxes, and the washing time for each box is 1.5 minutes. The parameters of relaxing washing are shown in Table 1.

[0019] Wherein, each washing temperature can be varied within the range of ±2°C, and the tension ratio and speed ratio in Table 1 correspond one by one. Because the gray cloth will shrink during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com