Laser-induced breakdown spectrum in-situ analyzer

A technology of laser-induced breakdown and in-situ spectroscopy, applied in material excitation analysis, optics, instruments, etc., can solve problems such as inability to obtain corresponding distributions, achieve the effects of increased analysis functions, rich information, and improved analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

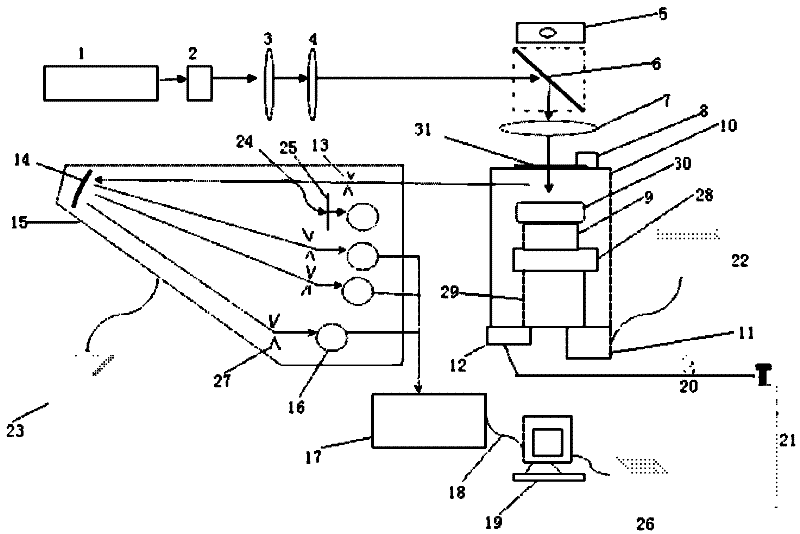

Method used

Image

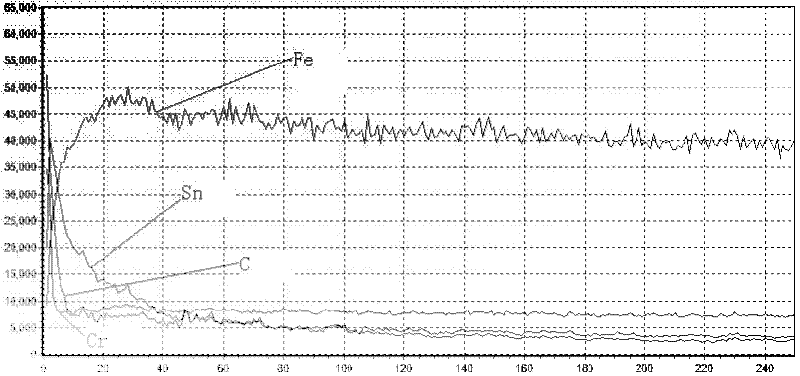

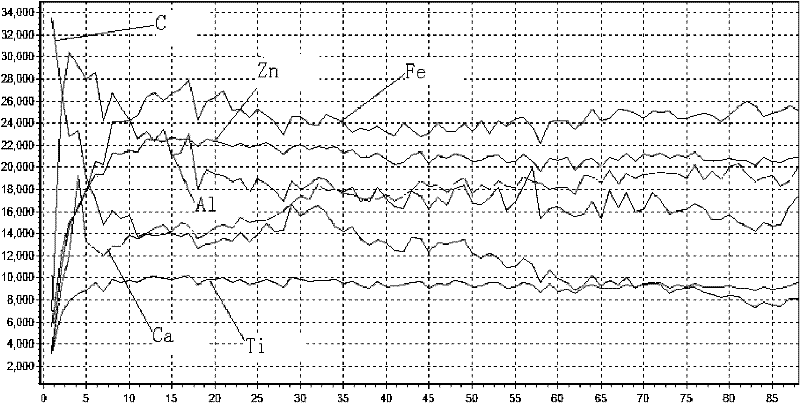

Examples

Embodiment 1

[0040] 1 Use the laser-induced breakdown spectrum in-situ analyzer of the present invention to analyze the element content of the standard sample of medium and low alloy steel (sample number: SS402 / 2):

[0041] Table 1 is a comparison table of the certified value of the low-alloy steel standard sample SS402 / 2 in the embodiment of the present invention and the measured value of the laser-induced breakdown spectroscopy in-situ analyzer.

[0042] Comparison of certified value and measured value of low alloy steel SS402 / 2 in Table 1 (measured 11 times)

[0043] times\elements

C

Si

Cu

Al

Mo

Ni

Cr

mn

1

1.404

0.113

0.288

0.138

0.14

0.816

0.624

0.221

2

1.303

0.112

0.288

0.138

0.135

0.71

0.633

0.229

3

1.365

0.113

0.294

0.141

0.138

0.781

0.621

0.217

[0044] 4

1.386

0.112

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com