Dynamic self-balance gas generating device and its application method

A gas generating device and gas generating technology, applied in the direction of electrochemical generators, electrical components, hydrogen production, etc., can solve the problems of unreliable hydrogen supply, inconvenient use in mobile places, difficult control of hydrogen production process, etc., and achieve raw material Utilization rate has no side reaction, improves hydrogen production efficiency, and has the effect of fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

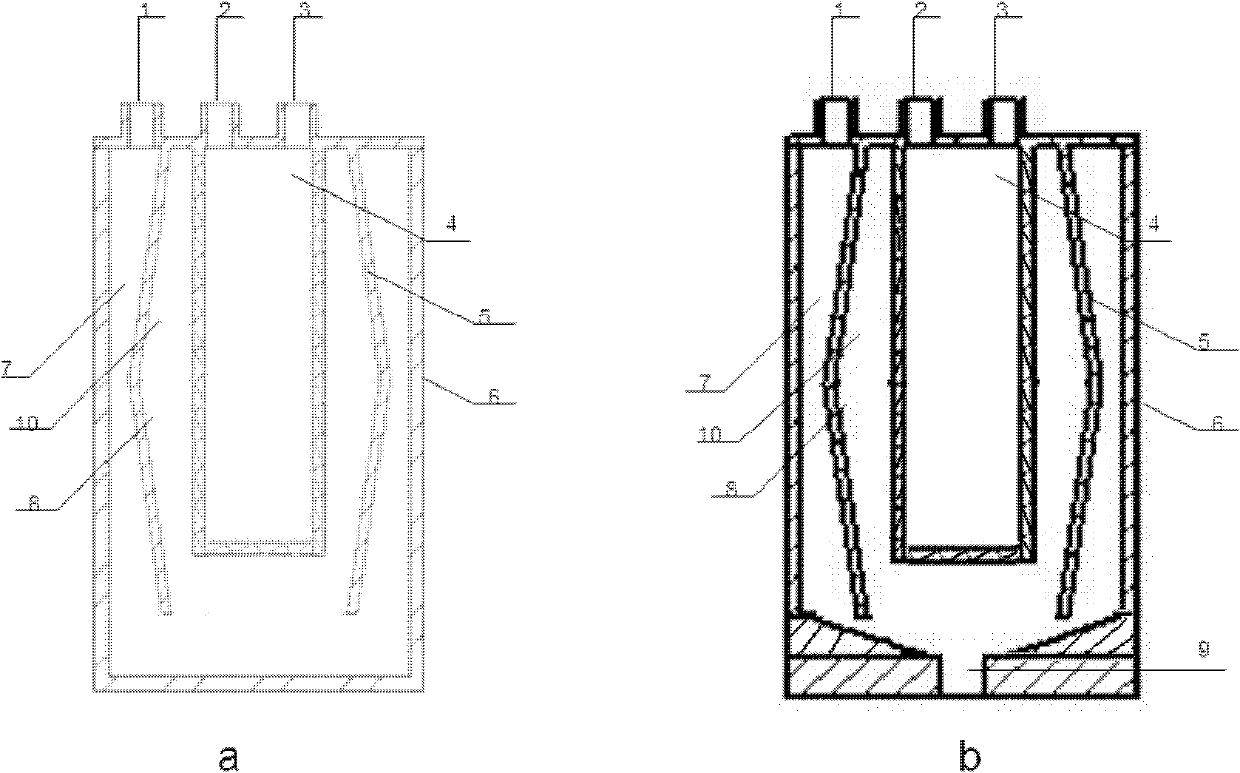

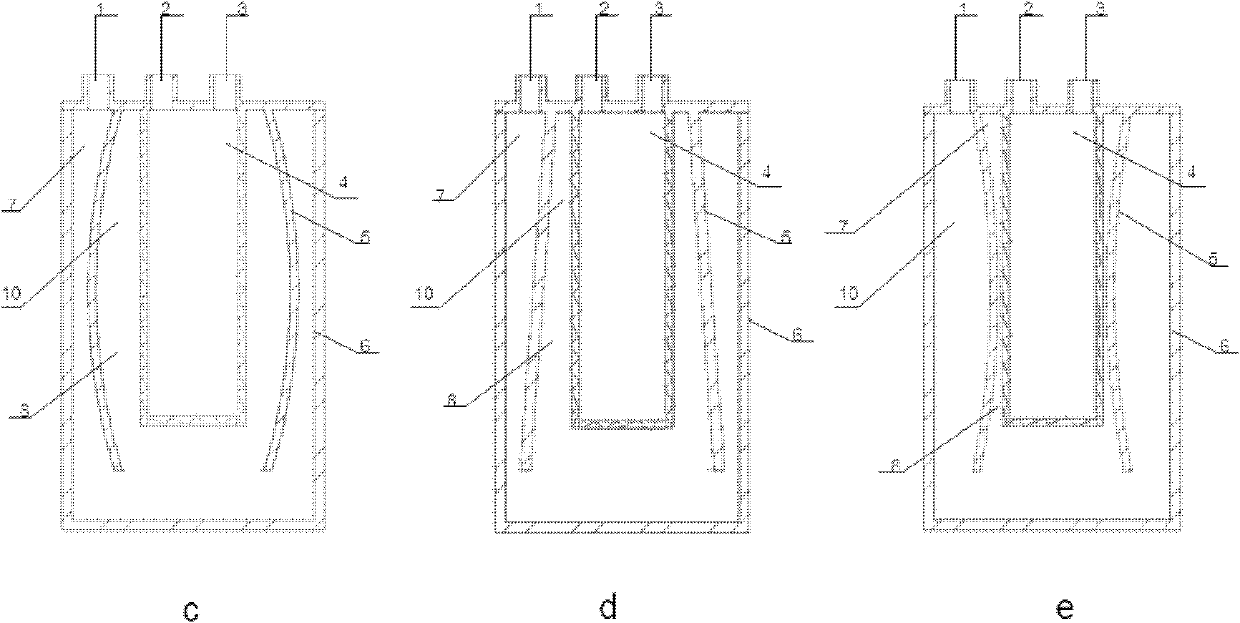

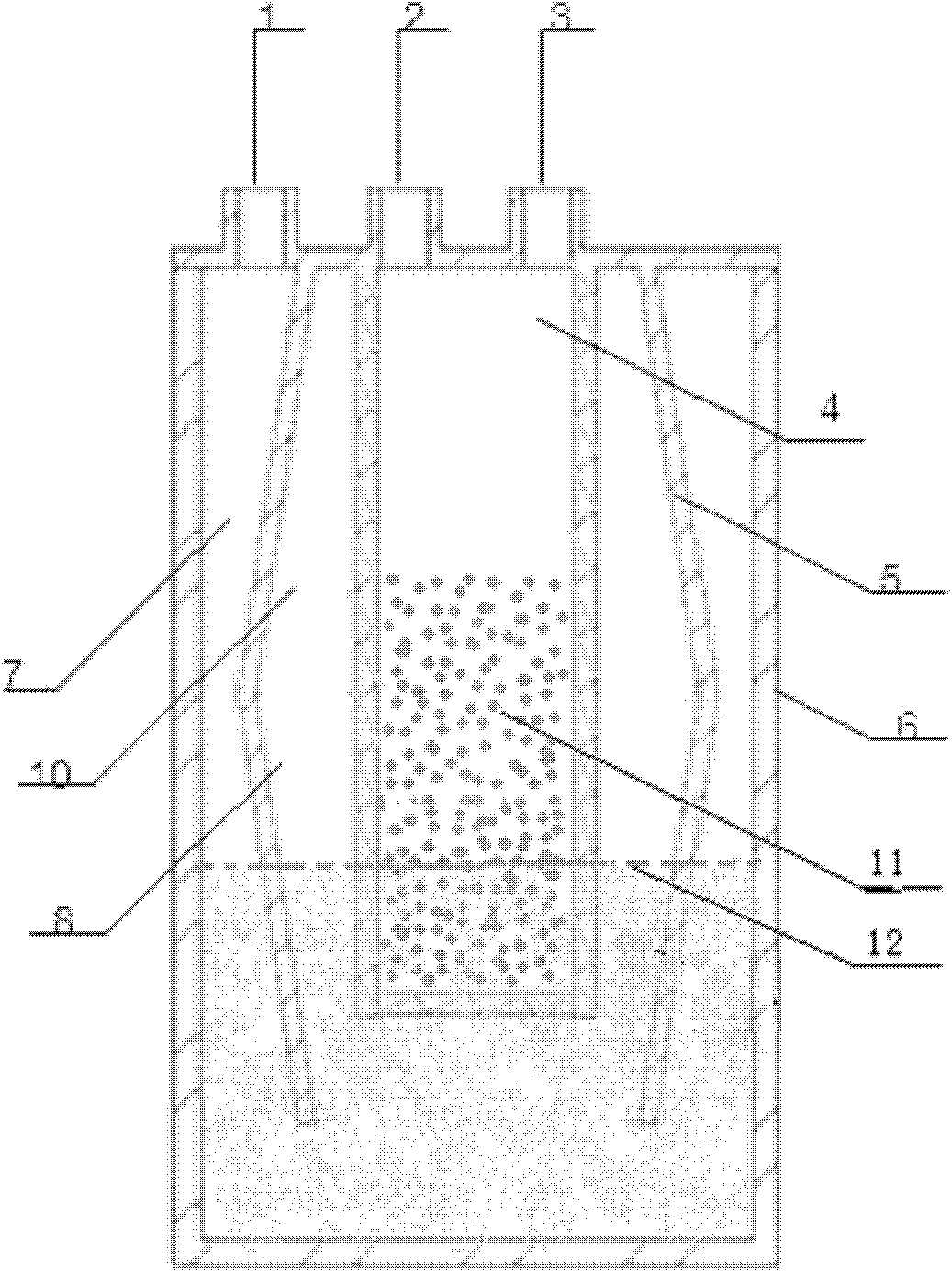

[0046] combined with figure 1 b The structure of the gas generating device in the dynamic self-balancing gas generating device provided by the present invention is stated in detail as follows: the device includes a gas generating tank 6, a material bin 4, a gas outlet 3, a gas collecting hood 5 and a gas pressure regulating port 1; The gas collecting hood 5 is arranged inside the gas generating tank 6, the bottom end of which is connected to the bottom end of the gas generating tank 6, and the top is airtightly connected with the top cover of the gas generating tank 6; the material bin 4 is a permeable mesh structure embedded Set inside the gas collecting hood 5, there is a gap between the outer side wall and the outer bottom wall of the gas collecting hood 6, the inner side wall and the bottom of the gas collecting hood 6, the top of the material bin 4 is airtightly connected with the top cover of the gas generating tank, so that the metal material and the gas The auxiliary a...

Embodiment 2

[0052] attached to figure 1 Add 240g of sodium hydroxide and 620g of water into the gas generating tank shown in a; add 80g of aluminum raw material with an average diameter of 1mm into the material bin, which is a 30-mesh polytetrafluoroethylene mesh, and the two react to generate hydrogen. After 1 minute, the hydrogen gas starts to be delivered, and after 3 minutes, the system tends to be stable, after which the reaction of the device is automatically adjusted. The hydrogen output rate was kept between 1 and 1.5 L / min within 10 to 60 minutes, and the reaction was terminated after 90 minutes.

[0053] When the hydrogen-requiring equipment stops working, close the gas outlet 3, the gas supply is completed, and at the same time open the gas pressure regulating port 1 and the feeding port 2, and directly open the gas generating tank to discharge the waste liquid.

Embodiment 3

[0055] Add 150g of sodium hydroxide to the attached figure 1 Add 700g of water to dissolve the gas generating tank shown in b; add 50g of aluminum raw material, with an average diameter of 0.6mm, into the material bin, which is made of 40-mesh stainless steel mesh, and the two react to generate hydrogen. After 1 minute, the hydrogen gas starts to be delivered, and after 3 minutes, the system tends to be stable, after which the reaction of the device is automatically adjusted. The hydrogen output rate was kept between 1 and 1.5 L / min within 10 to 35 minutes, and the reaction was terminated after 40 minutes.

[0056] When the hydrogen-requiring equipment stops working, close the gas outlet 3, the gas supply is completed, and at the same time open the gas pressure regulating port 1 and the feeding port 2, and directly open the gas generating tank attachment figure 1 b Bottom drain port 9 to discharge waste liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com