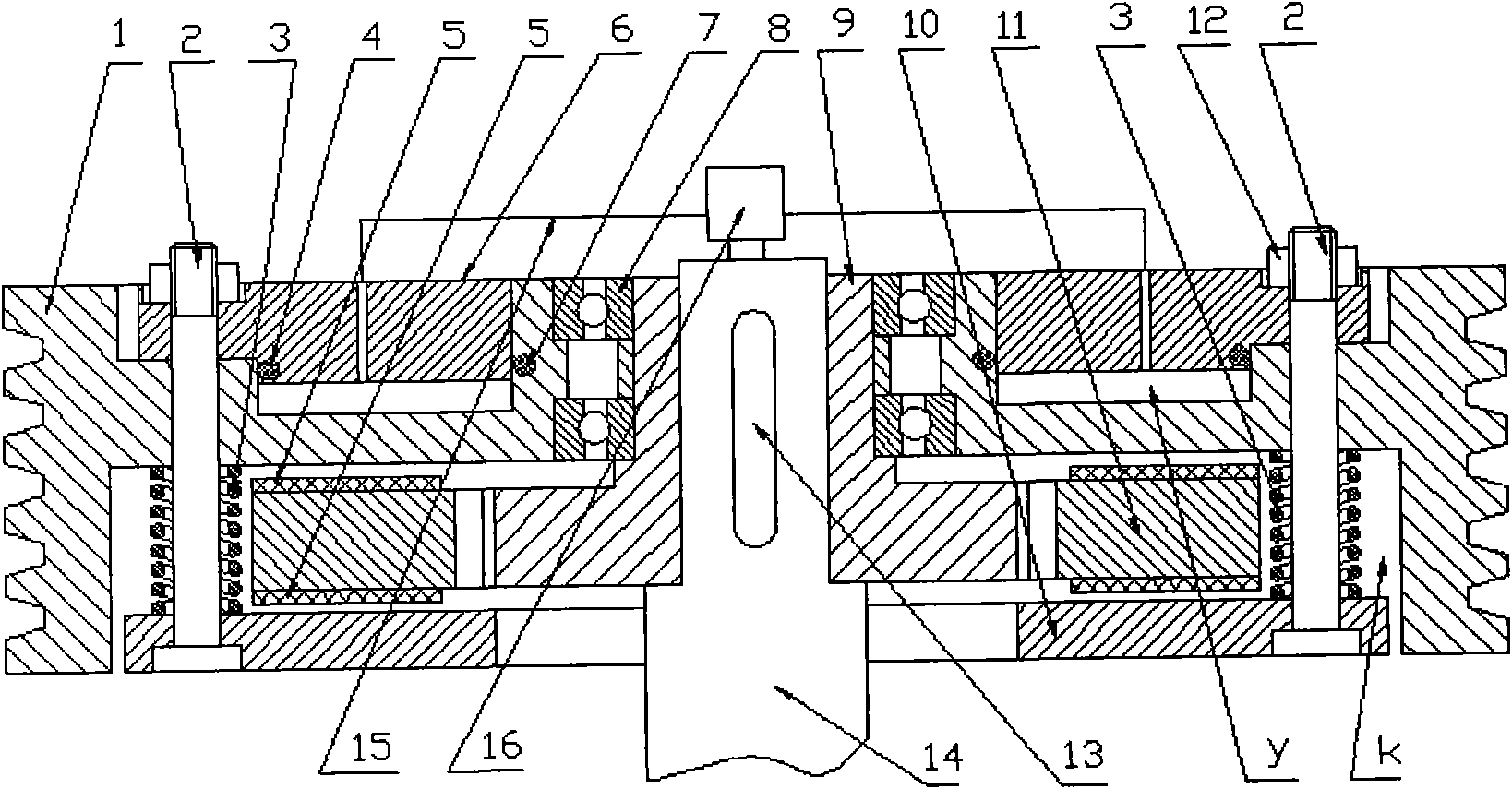

Flywheel and clutch integrated transmission mechanism

A kind of transmission mechanism and integrated technology, applied in the field of mechanical transmission, can solve the problems of large mechanism, high cost, unfavorable use of space, etc., and achieve the effect of overcoming high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

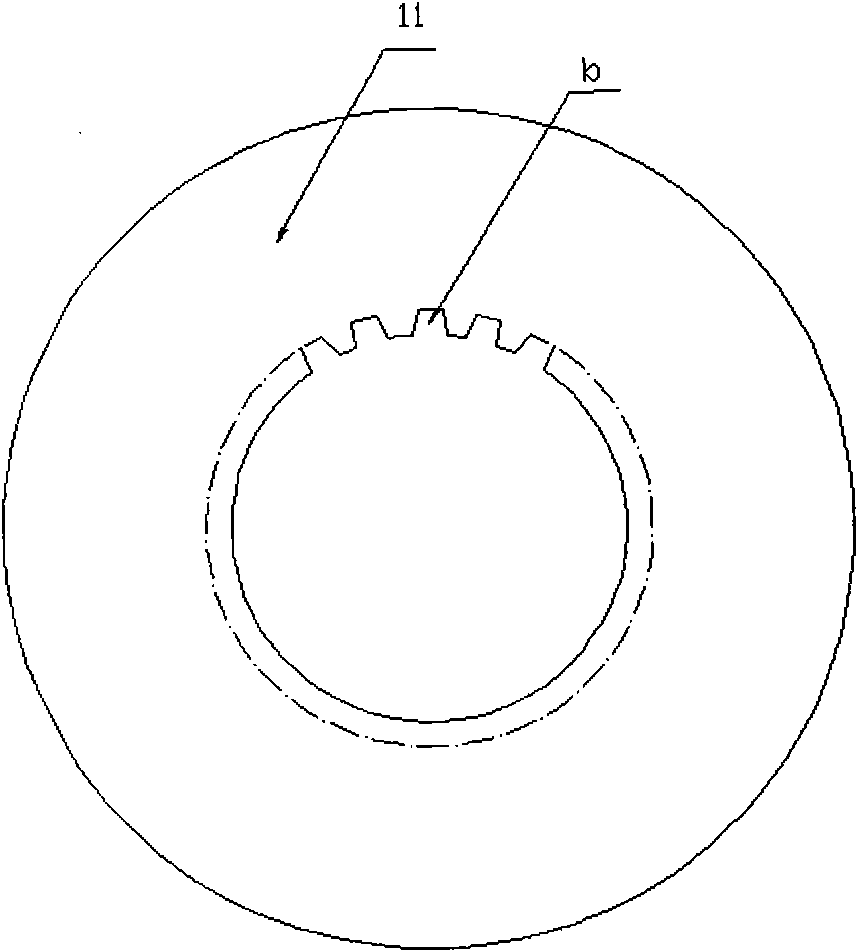

[0013] The driving body (9) is installed and fixed on the transmission shaft (14) with a key (13), and a fixed connection relationship is formed between the driving body (9) and the transmission shaft (14); the driving body (9) has two outer circles, large and small. Convex and concave teeth a are evenly distributed on the large outer circle of the driving body (9), and fixed friction plates (5) are installed on both sides of the driving disc (11) by riveting, and are manufactured at the center of the driving disc (11) There is a round hole, and the concave-convex teeth b similar to those on the outer circle of the driving body (9) are made on the inner surface of the round hole, and the driving disc (11) is engaged with the driving body (9) through the concave-convex teeth b on the inner circle. ) on the concave-convex tooth a on the outer circle, there is a relative sliding degree of freedom between the driving disc (11) and the driving body (9) along the concave-convex tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com