Mold structure with glue-feeding rear mold

A technology of mold and back mold, which is applied in the mold structure field of back mold injection, which can solve the problems of high appearance requirements and failure to meet the appearance requirements of injection molding products.

Inactive Publication Date: 2011-11-16

VANGUARD TECH WUXI

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Existing appearance products have high requirements on the appearance of the exposed parts, such as notebook casings, and the existing front mold injection molds cannot meet the appearance requirements of their injection molding products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

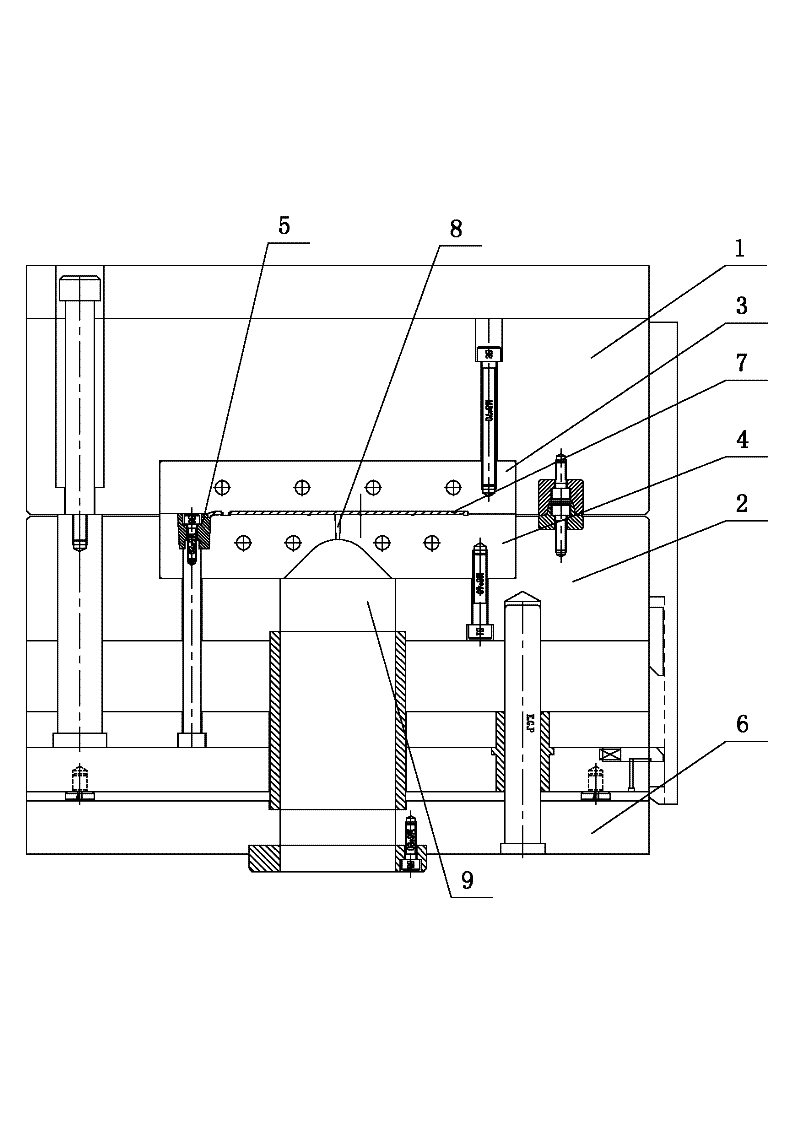

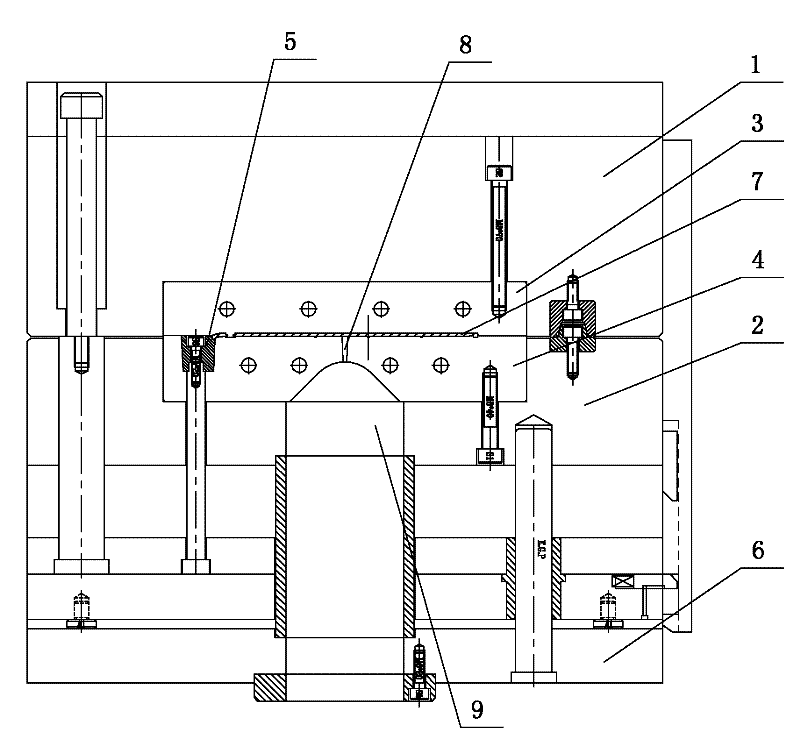

[0007] See figure 1 , which includes A plate 1, B plate 2, front mold 3, back mold 4, insert 5, bottom plate 6, the cavity between the front mold 3, back mold 4, and insert 5 is a mold cavity, and inside the mold cavity is The product 7 is provided with a glue inlet 8 on the rear 4, and the glue inlet 8 is connected to the injection nozzle 9 of the injection molding machine.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a mold structure with a glue-feeding rear mold. By the mold structure, the aesthetic appearance of a part exposed out of a product is ensured, and apparent visual requirements are met. The mold structure comprises a plate A, a plate B, a front mold, a rear mold, an insert and a bottom plate, wherein a cavity among the front mold, the rear mold and the insert is a die cavity. The mold structure is characterized in that: a glue-feeding hole is formed in the rear mold and is communicated with an injection molding nozzle of an injection molding machine; and the injection molding nozzle is positioned at the lower end of the die cavity and is fastened to the bottom plate.

Description

technical field [0001] The invention relates to the structural technical field of product molds, in particular to a mold structure for back mold injection. Background technique [0002] Existing appearance products have high requirements on the appearance of the exposed parts, such as notebook casings, and the existing front-mold injection molds cannot meet the appearance requirements of the injection molding products. Contents of the invention [0003] The invention provides a mold structure with glue feeding in the back mold, which ensures the beautiful appearance of the exposed part of the product and meets the visual requirements of the appearance. [0004] The mold structure of back mold feeding, it comprises A plate, B plate, front mold, back mold, insert, base plate, the cavity between described front mold, back mold, insert is mold cavity, it is characterized in that: A glue inlet is opened on the rear mold, and the glue inlet communicates with the injection nozzl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C45/26

Inventor 张卫

Owner VANGUARD TECH WUXI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com