foil beat device

A technology of applying device and transfer foil, which is applied in printing, rotary printing machine, printing machine, etc., can solve the problems of position change, tension change, influence on belt tension itself, etc., and achieve the effect of high takt speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

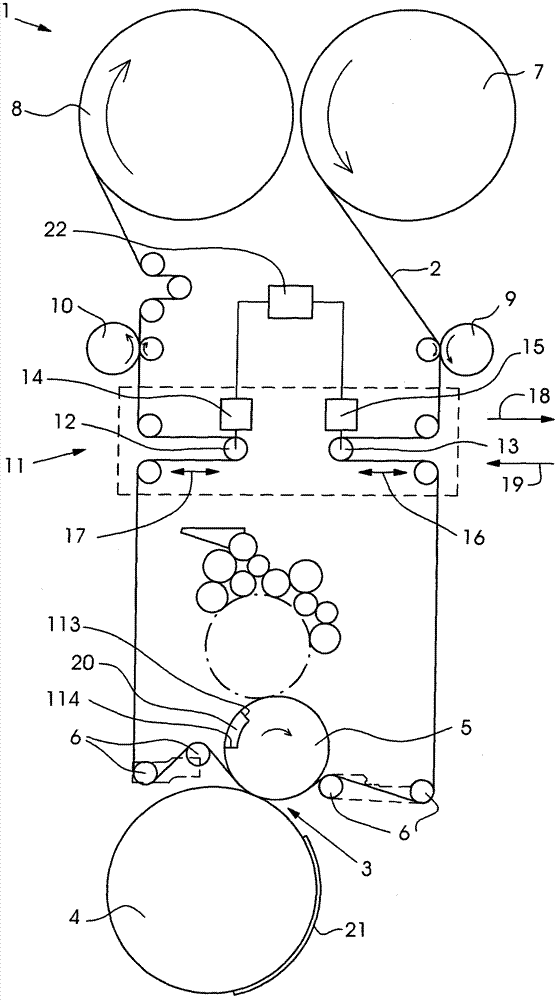

[0021] figure 1 shows a foil transfer device 1 in which a transfer foil 2 is guided through a transfer nip 3 .

[0022] The transfer nip 3 is formed by a transfer cylinder 5 and an impression cylinder 4 . The transfer foil 2 is unwound from the supply roll 7 and pulled by a front puller 9 in the direction of the transfer nip 3 . The supply roll 7 rests on a friction shaft (not shown here) and is driven at a speed that is lower than the speed of the printing material 21 . The drive of the supply roll 7 takes place via a friction shaft. The transfer foil 2 is drawn off the supply roll 7 via the front puller 9 , the rollers of the front puller 9 being driven at a speed higher than the friction shaft speed of the supply roll 7 . However, the front drawer 9 always works at a speed that is lower than the speed of the printing material 21 .

[0023] The unwound transfer foil 2 is guided through the transfer nip 3 via the front float 13 of the clock module 11 and via the further d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com