Double-row waste winding mechanism for label punching

A rewinding mechanism and waste rewinding technology, which are used in thin material processing, coiling strips, conveying filamentous materials, etc., can solve the problems of inability to remove the annular waste belt, large tension changes, etc., and achieve the transformation cost. Low cost, high economic value, the effect of maintaining reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

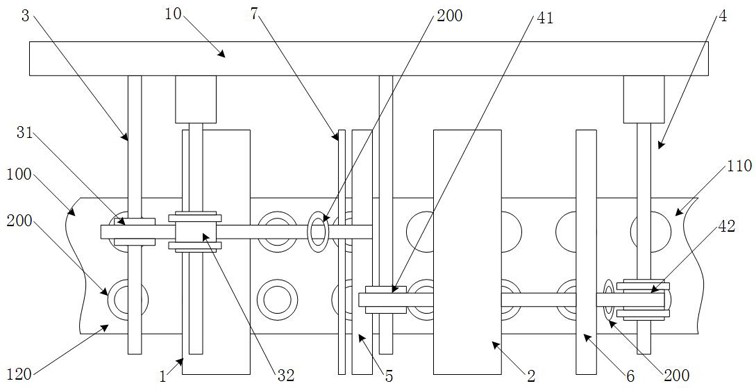

Image

Examples

Embodiment 1

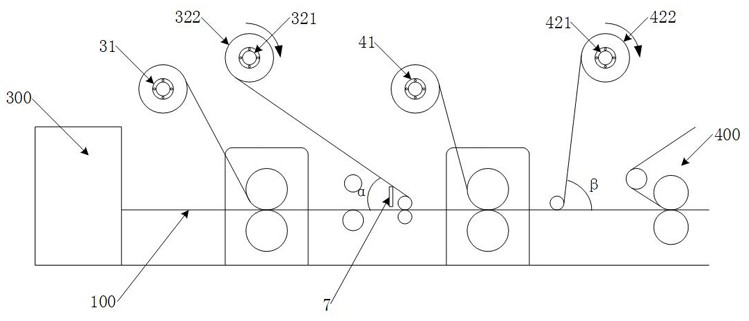

[0052] like figure 2 As shown, the first tape rewinding portion 32 includes a first rotating shaft 321 provided with a rotational drive source and a first reeling reel 322 provided on the first rotating shaft, and the second tape rewinding portion 42 includes a rotating drive source. The second rotating shaft 421 and the second winding material shaft 422 arranged on the second rotating shaft.

[0053] That is, two independent drive source rotating shafts are used to meet the needs of independent tension control and stable winding.

Embodiment 2

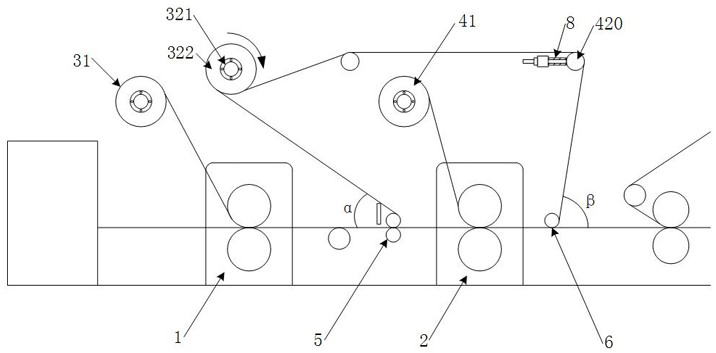

[0055] like image 3 As shown, the first tape rewinding part 32 includes a first rotating shaft 321 with a rotational drive source and a first reeling material shaft 322 provided on the first rotating shaft, and the second tape rewinding part 42 includes a first reeling shaft 322 provided on the first rotating shaft A second reel spool 422 on the rotating shaft and several steering shafts 420 for tape steering. Either steering shaft has a tension adjustment displacement.

[0056] Specifically, a rotating shaft is used to realize the synchronous tape rewinding of double-row waste materials, so that the cost can be controlled. At the same time, by adjusting the displacement of the tension of the steering shaft, it can meet the matching requirements of different strokes of the tape tension, making the rewinding operation more stable and reliable. .

[0057] The steering shaft 420 is realized by a floating tension control part 8 with a linear floating displacement, and has a sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com