Sand core rod pre-tightening device

A core bone and sand core technology, applied in the field of metallurgical casting, can solve problems such as defects, uneven inner walls or holes of castings, and scrapping, and achieve the effect of enhancing the rigidity of the core bone and the rigidity of the sand core.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

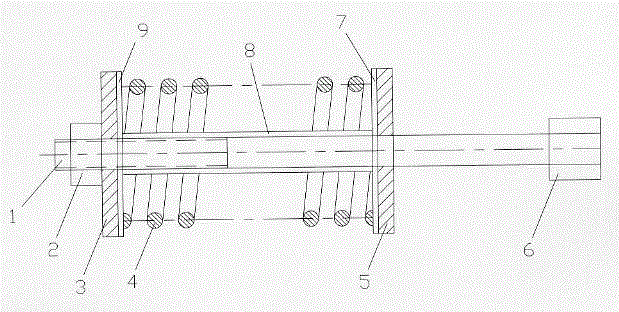

[0022] see figure 1 , The present invention provides a pre-tightening device for sand core core, which is mainly composed of a shaft 1, a coupling 6, two bearing plates 3, 5, a pre-tightening compression spring 4 and a nut 2.

[0023] A coupler 6 is arranged at one end of the shaft 1, and the coupler 6 is connected with the mandrel. Install two opposite force bearing plates 3,5 on the shaft 1, and pre-tightening compression spring 4 is set between the two force bearing plates 3,5.

[0024] At the other end of the shaft 1 and on the outside of one of the bearing plates 3, a nut 2 is screwed, so that the deformation of the pre-tightening compression spring 4 produces a pre-tightening force, and another bearing plate 5 leans against the outside of the sand box.

[0025] The pre-tightened compression spring 4 is provided with an insulating material 8 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com