Corner type main shaft

A spindle and angle technology, which is applied to the parts of grinding machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of complicated production management, high center of gravity, increased column bending moment load, etc., and achieve the transformation of operation and production The effect of work simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] The foregoing and other technical contents, features and effects of the present invention will be clearly understood in the following detailed description of a preferred embodiment with reference to the accompanying drawings.

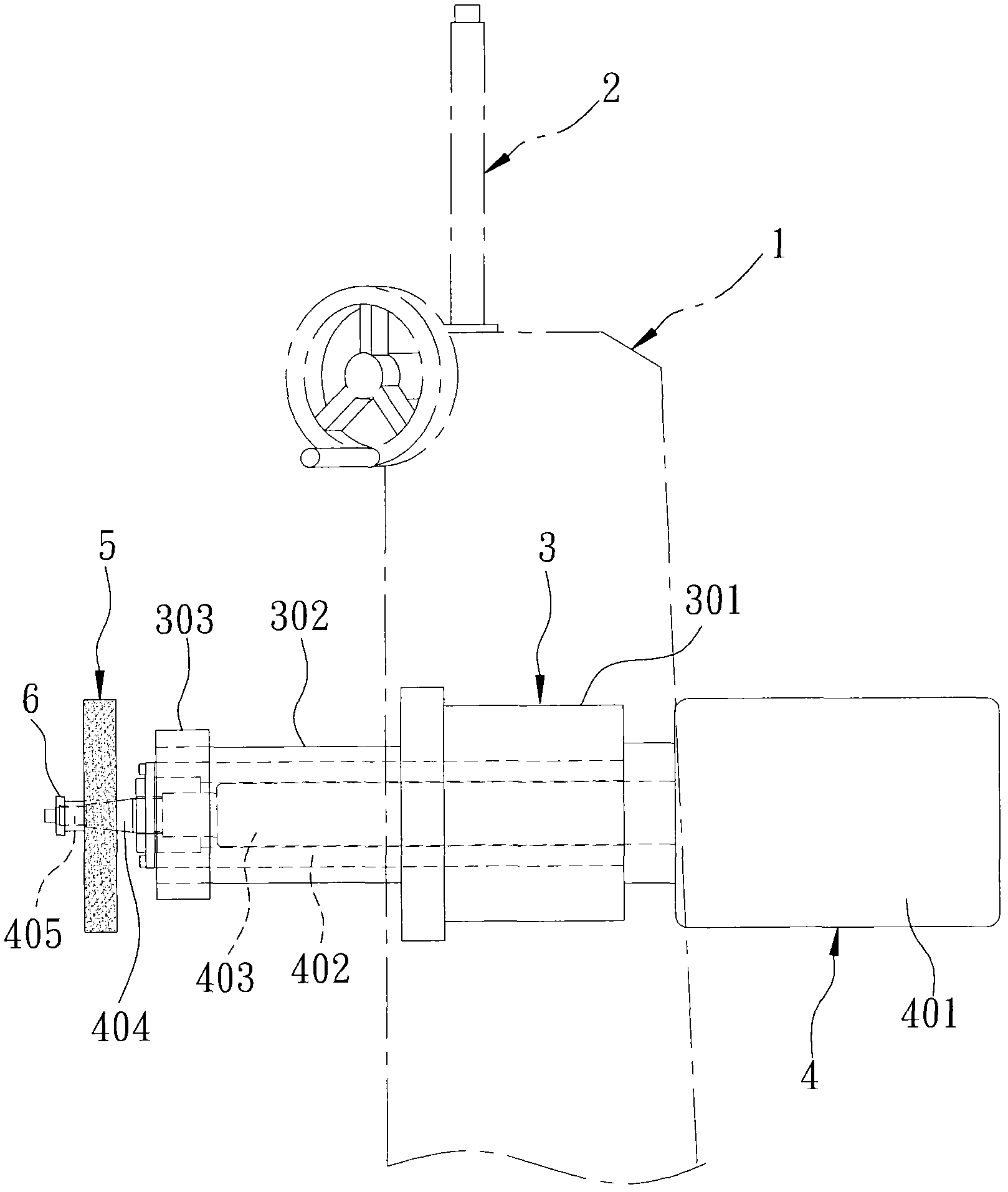

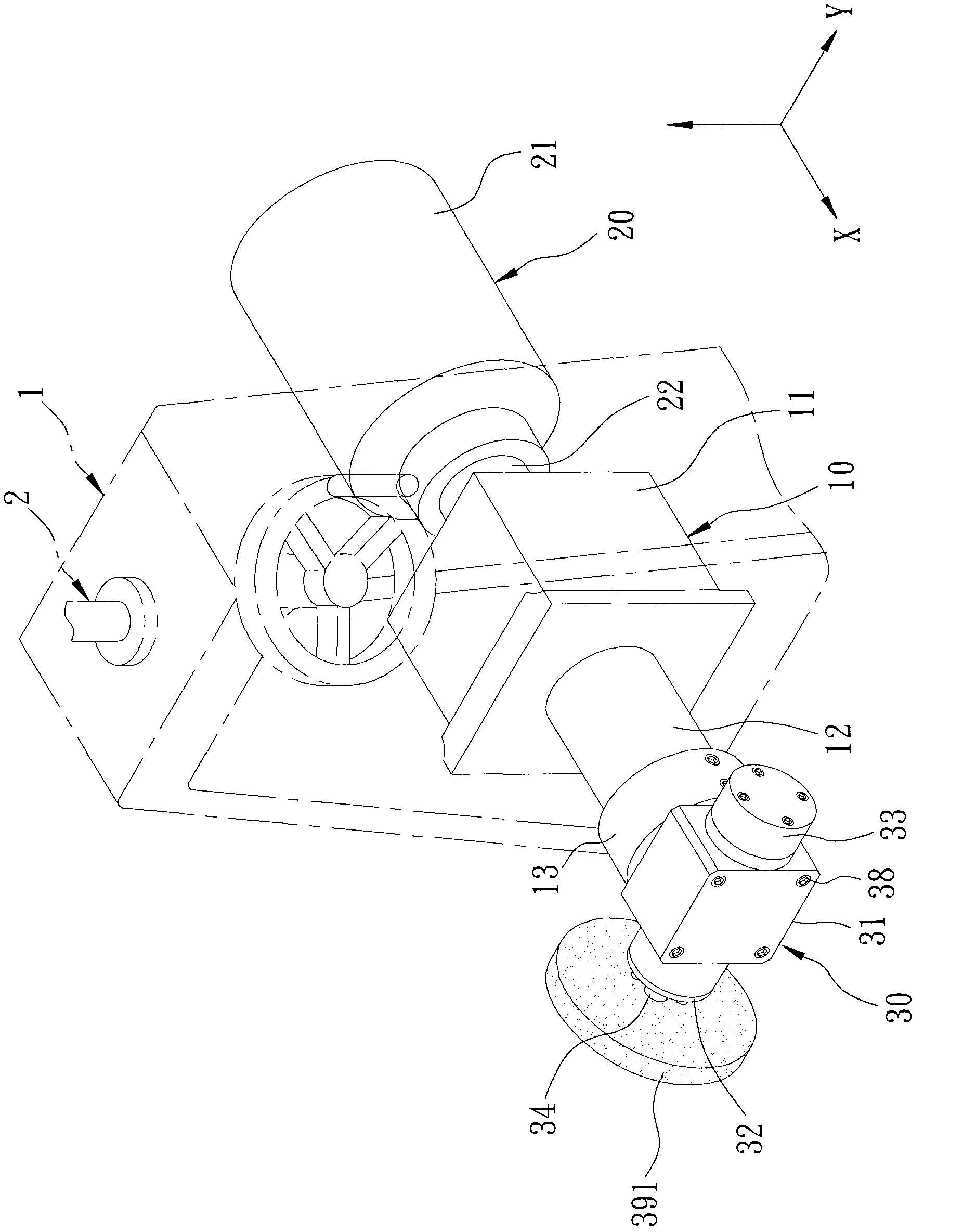

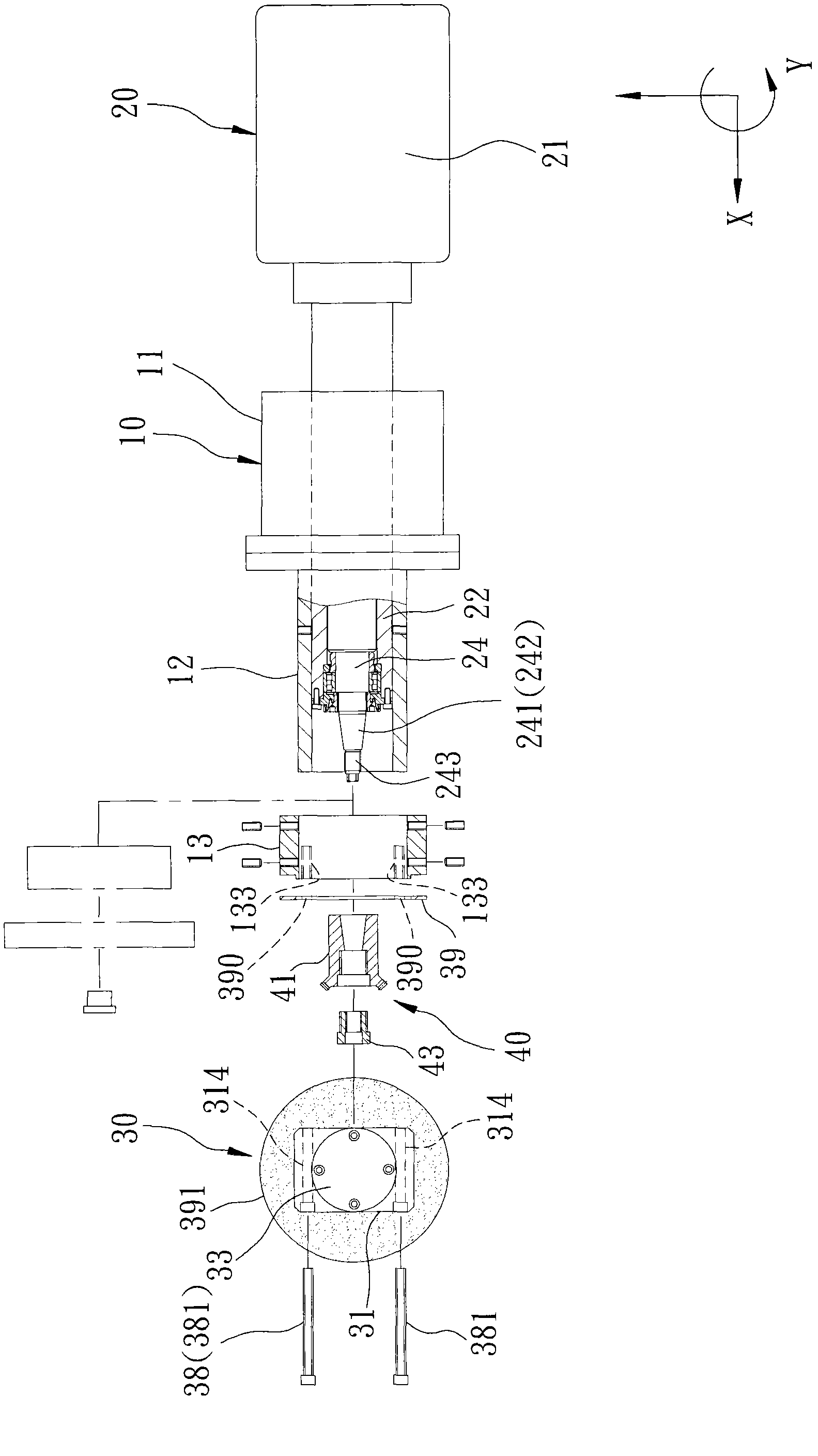

[0034] refer to figure 2 , 3 , which is a preferred embodiment of the angled spindle of the present invention, the angled spindle includes: a saddle unit 10 , a spindle unit 20 , an output unit 30 , and a transmission unit 40 .

[0035] Such as image 3 , 4, 5, the saddle unit 10 has a main body 11, an outer tubular body 12 extending forward from the main body 11 along a first axis X, and a detachably arranged front end of the outer tubular body 12 The positioning part 13. It is worth noting that the shape of the outer tube body 12 is not limited to a round tube, but may also be a square tube.

[0036] The positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com