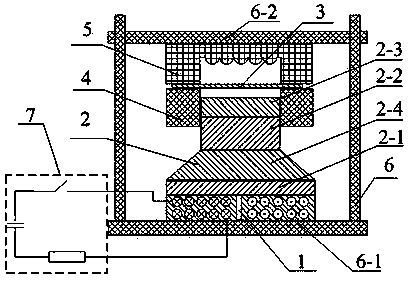

Electromagnetic drive forming method and device

A technology of electromagnetic drive and drive plate, which is applied in the direction of forming tools, metal processing equipment, stamping machines, etc., can solve the problems of low efficiency and poor electromagnetic forming mold-fitting performance, achieve good fluidity, solve poor mold-fitting performance, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

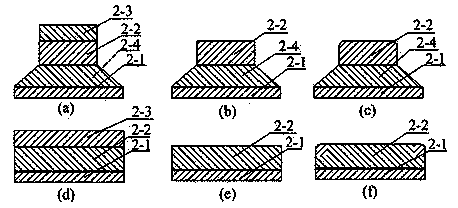

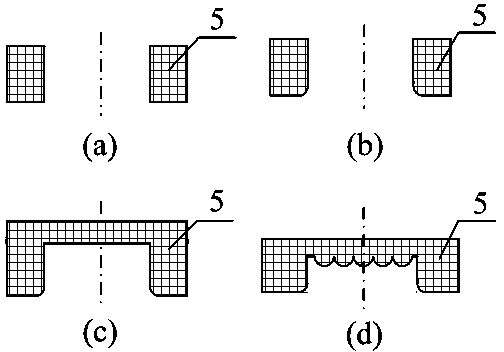

[0044] 8mm thick 5a06 aluminum alloy tube plate is used as the workpiece 3, and a single-hole punching die 5 with a diameter of 50mm is selected. figure 2 The composite punch 2 with die steel pressure amplifier shown in (b) is installed according to the schematic diagram of the electromagnetic drive forming device; the power supply control system 7 is used to supply power to the drive coil 1 to complete the single hole punching process and take it out for processing The 8mm thick 5a06 aluminum alloy plate 50mm diameter punching workpiece, the formed workpiece is as Figure 4 (a) shown.

Embodiment 2

[0046] Adopt 0.1mm thick pure copper material as processing workpiece 3, select porous punching die 5, use figure 2The punching composite punch 2 shown in (e) without the die steel pressure amplifier is installed according to the schematic diagram of the electromagnetic drive forming device; the power supply control system 7 is used to supply power to the drive coil 1, and the porous punching process is completed, and the process is taken out. 0.1mm thick 5a06 pure copper plate porous punching workpiece, its forming workpiece is as Figure 4 (b) shown.

Embodiment 3

[0048] Use 5mm thick 5a06 aluminum alloy plate as workpiece 3, select flanging die 5, use figure 2 The flanging with die steel pressure amplifier shown in (c) and the simple structure forming composite punch 2 are installed according to the schematic diagram of the electromagnetic drive forming device; the power supply control system 7 is used to supply power to the driving coil 1 to complete the flanging process and take it out The processed 5mm thick 5a06 aluminum alloy plate 30mm diameter flanging workpiece, the formed workpiece is as Figure 4 (c) shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com