Piston type tangent drive straight shaft internal combustion engine and control method thereof

An internal combustion engine, piston technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of low thermal efficiency of piston internal combustion engines, and achieve the effects of reducing weight, reducing costs, and saving structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

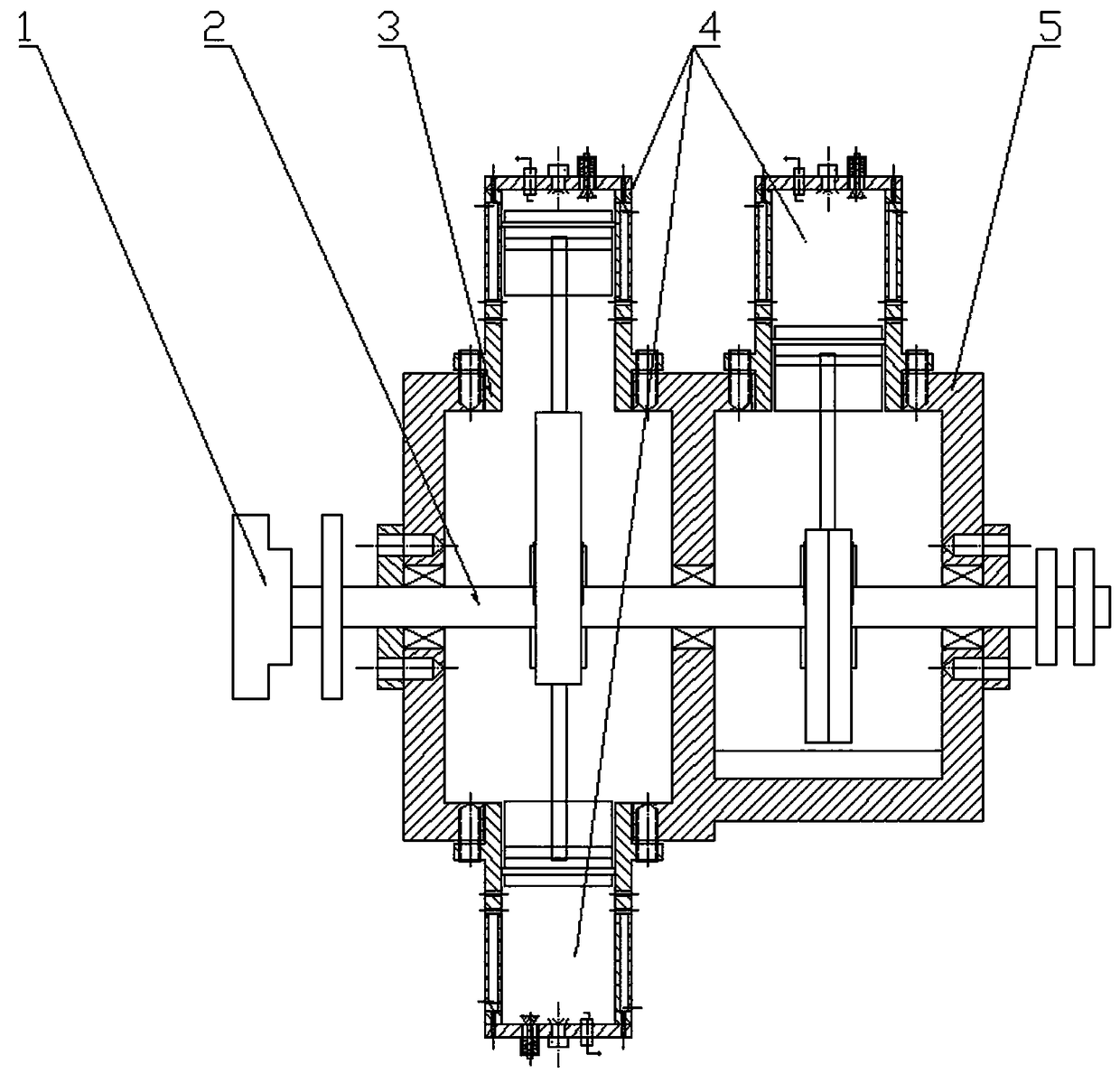

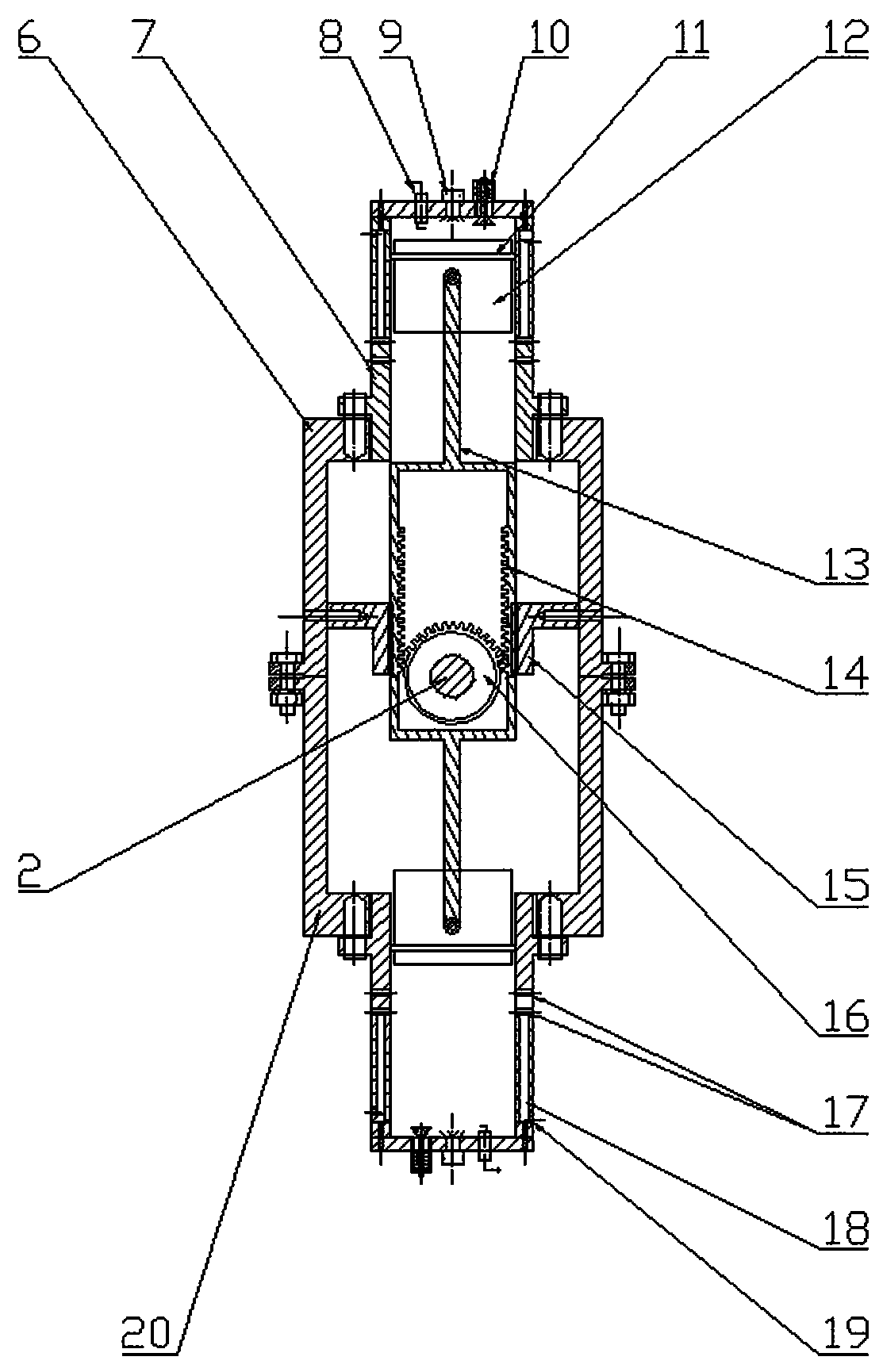

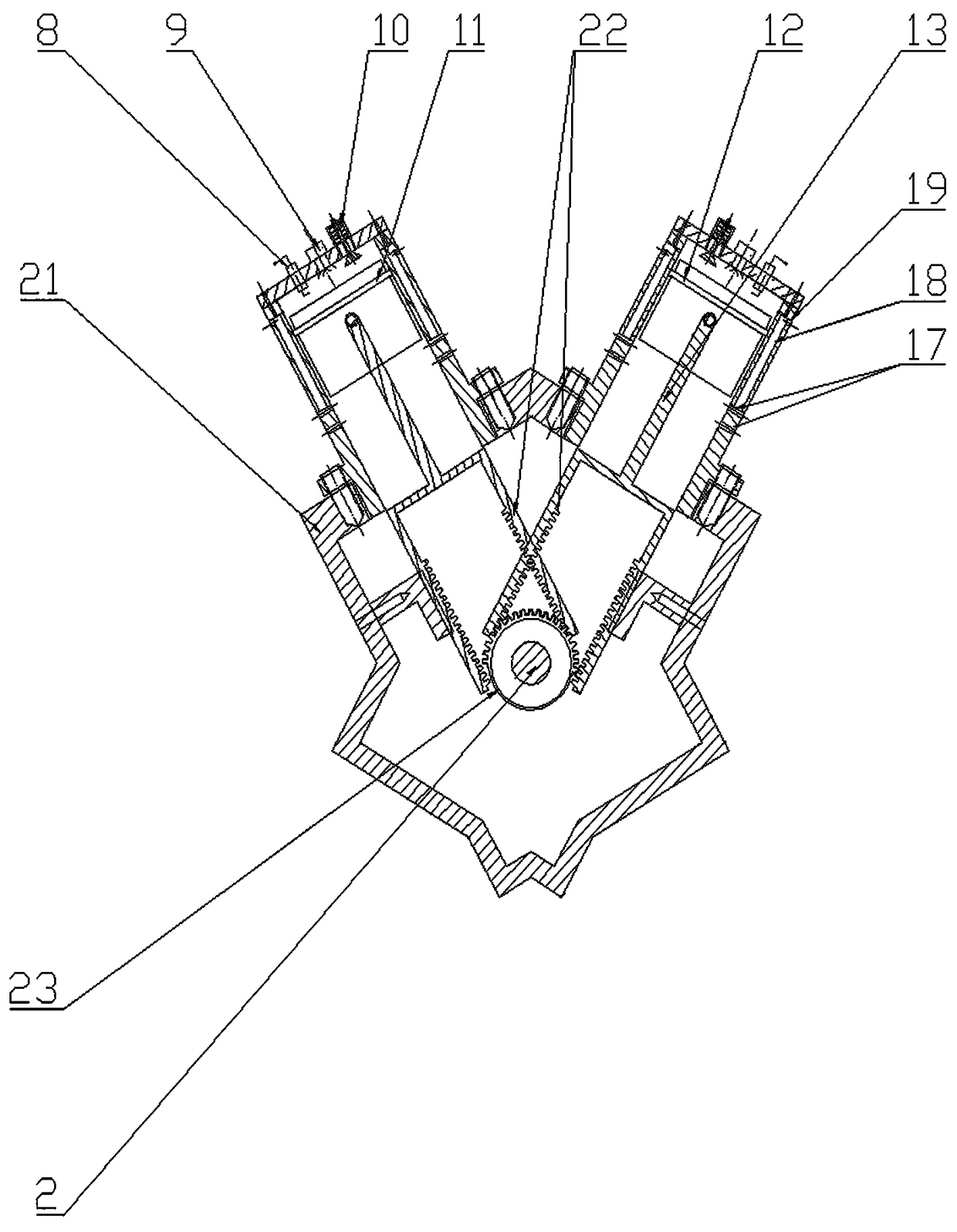

[0037] Example: such as Figure 1~5 As shown, a piston-type tangentially driven direct-shaft internal combustion engine includes an engine shaft connecting flange 1, an engine shaft 2 embedded with the engine shaft connecting flange 1 is provided on the end surface of the engine shaft connecting flange 1, and the engine shaft directly The shaft 2 is respectively provided with a same-direction half-circle gear 16 and a different-direction half-circumference gear 23 at equal intervals, and the side of the engine shaft connection flange 1 is respectively equipped with an I-type internal combustion engine that is movable with the engine direct shaft 2 3. V-shaped internal combustion engine 5, the same-direction half-cycle gear 16 is arranged in the I-type internal combustion engine 3 and is in relative rotational mesh with the I-type internal combustion engine 3, and the same-direction half-cycle gear 16 includes a gear plate 24 fixedly socketed with the engine straight shaft 2 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com