The synchronous lifting and lowering linkage mechanism of the transfer table

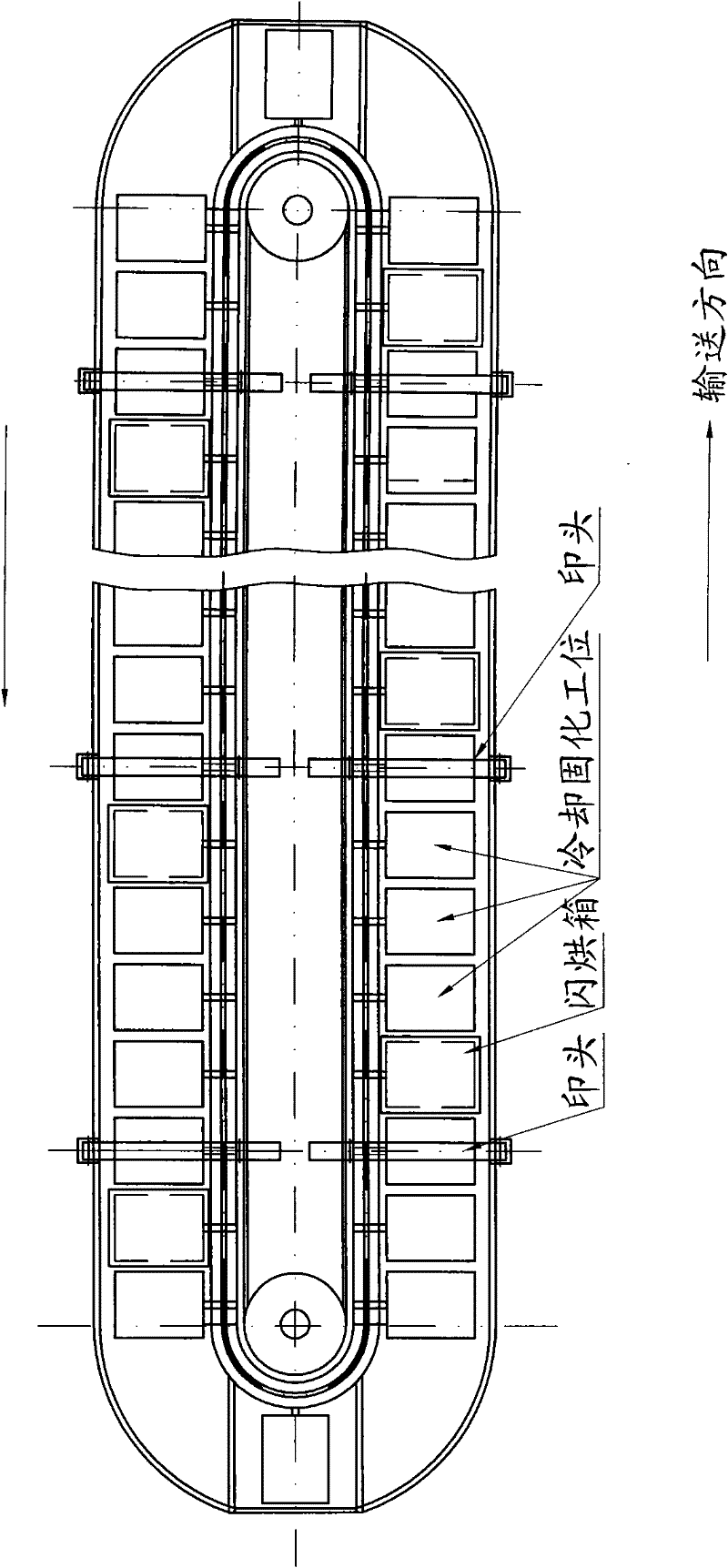

A linkage mechanism and transfer technology, applied in printing presses, rotary printing presses, screen printing presses, etc., can solve the problem of prolonging the flash drying time of the flash oven and the drying speed of the ink, increasing the area and space of the equipment, and difficult for enterprises. Accept and other problems to achieve the effect of preventing epitaxial collapse under pressure cracking, ensuring the quality of printing patterns, and good cooling and solidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

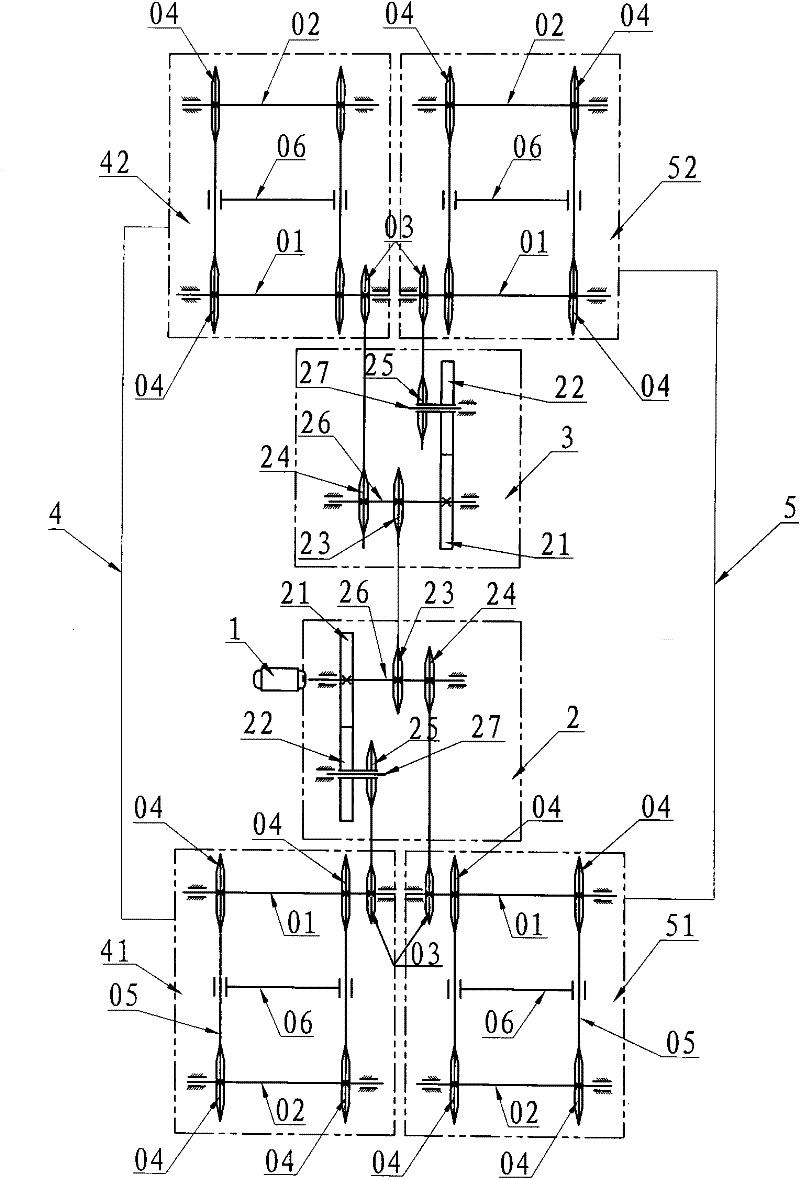

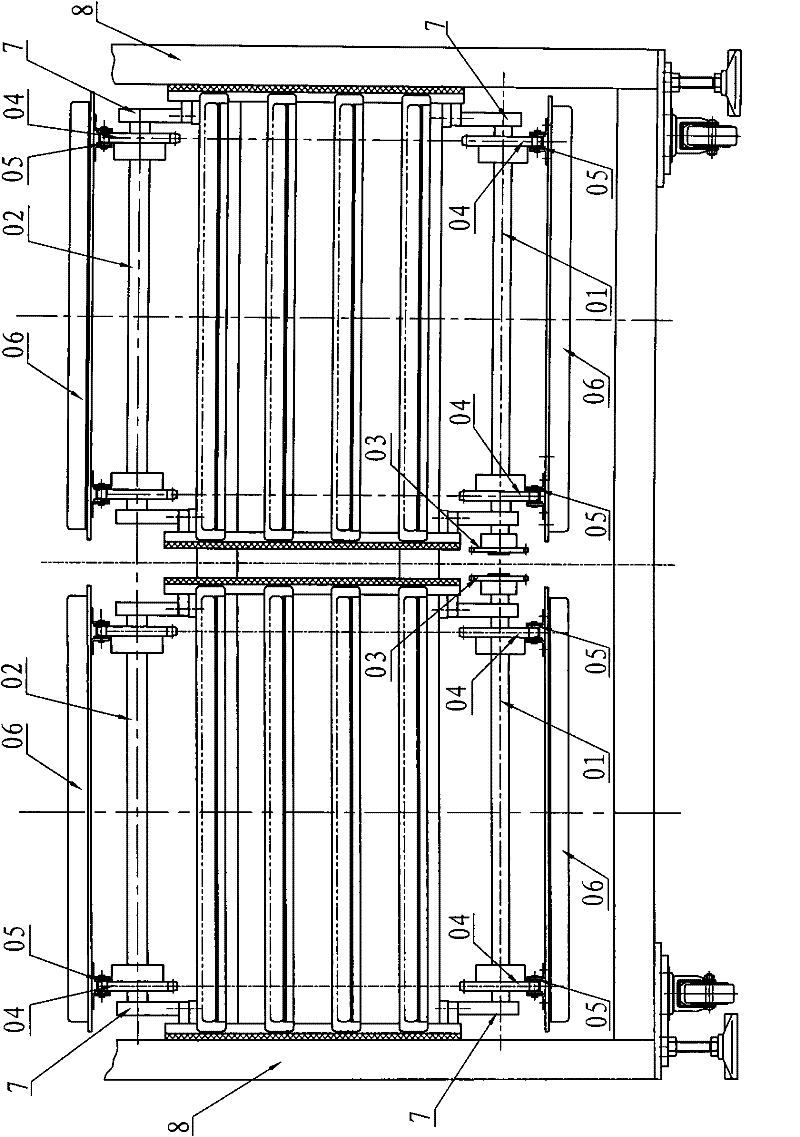

[0024] Embodiment 1: A synchronous lifting and lowering linkage mechanism of the transfer platform, such as Figure 2 ~ Figure 6As shown, it includes a reducer 1, an outer transmission box 2, an inner transmission box 3, a synchronous lowering mechanism 4, a synchronous rising mechanism 5, a bearing seat 7 and a frame 8, the reducer 1 drives the outer transmission box 2, and the outer transmission box 2 Drive inner transmission case 3, described outer transmission case 2 comprises driving gear 21, driven gear 22, transmission sprocket I 23, transmission sprocket II24, transmission sprocket III25, driving shaft 26 and driven shaft 27, in driving shaft Driving gear 21, transmission sprocket I 23 and transmission sprocket II 24 are fixedly equipped with on 26, and driven gear 22 and transmission sprocket III25 are housed on driven shaft 27, and driving gear 21 is meshed with driven gear 22, and driving Gear 21 and driven gear 22 have the same number of teeth, and the number of te...

Embodiment 2

[0025] Embodiment 2: In Embodiment 1, the drive shaft 26 in the outer transmission case 2 driven by the reducer 1 is changed to drive the driven shaft 27, and the driven gear 22 and the drive sprocket III25 are all fixedly installed on the driven shaft 27.

[0026] There are many embodiments of the present invention. The reducer 1 can also drive the driving shaft 26 or the driven shaft 27 in the inner transmission box 3, and can also drive any transmission interface in the entire transmission system. No matter what kind of transmission structure is adopted, as long as it can Ensure that the synchronous lowering mechanism and the synchronous rising mechanism turn to the opposite direction and have the same rotational speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com