Tower type centrifugal-spraying differential action pelleting device

A granulating device and tower-type technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of droplets that cannot be effectively cooled and solidified, and easy to block the nozzle orifices of the nozzles, so as to prevent the separation and solidification of solid and liquid layers. Good effect, the effect of avoiding production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

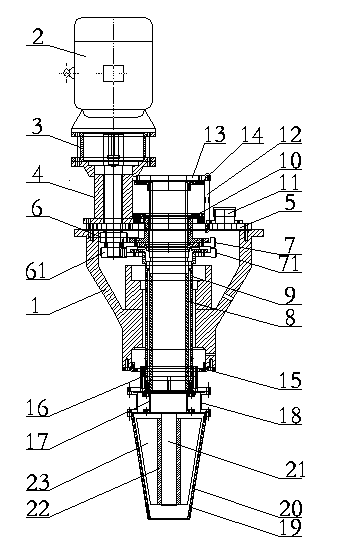

[0018] figure 1 As shown, a tower-type centrifugal spray differential granulation device includes a casing 1, a motor 2, a bracket 3, a bearing seat 4, an upper cover plate 5, an upper tooth portion 6, a lower tooth portion 61, an upper gear 7, a lower gear Gear 71, inner shaft 8, outer shaft 9, gland 10, fuel cap 11, connecting rod 12, support plate 13, upper flange 14, bottom gland 15, nozzle seat 16, inner shaft connection seat 17, outer shaft connection Seat 18, nozzle housing 19, nozzle hole 20, inner shaft pull rod 21, distributor 22 and scraper 23. The upper end of the casing 1 is encapsulated by the upper cover plate 5, the motor 2 is supported on the upper cover plate 5 through the bracket 3 and the bearing seat 4, and the input shaft of the motor 2 does not coincide with the axis of the casing 1, and the motor 2 extending into the casing 1 The input shaft is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com