Method for changing conical degree at moment of obstructing process of on-line width reduction of continuous casting crystallizer

A continuous casting mold and width reduction technology, which is applied in the field of continuous casting mold online taper change, can solve problems such as unfavorable equipment use and safety production impact, and achieve the effects of convenient operation, lower production costs, and improved market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

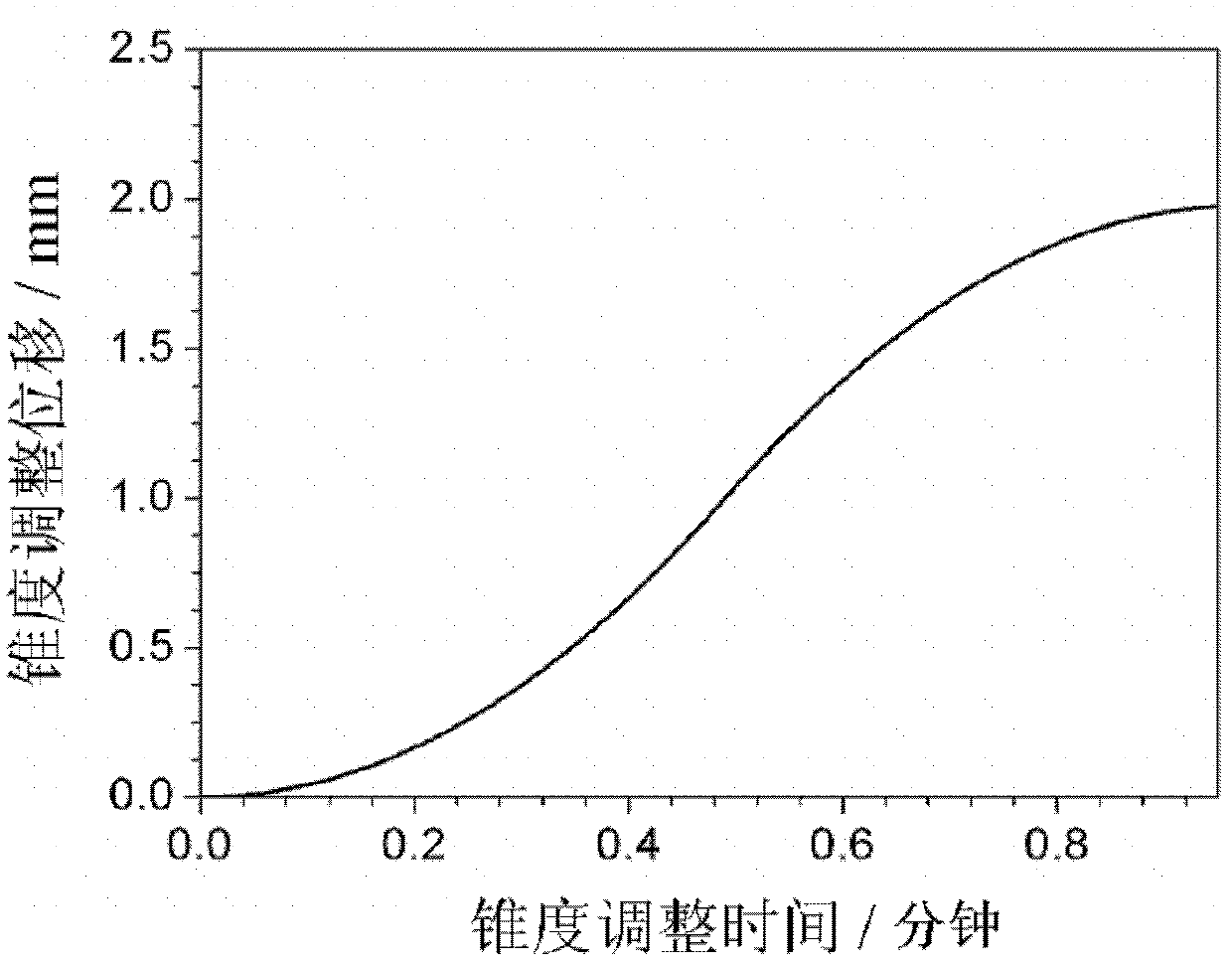

[0049] The taper on one side of the mold is 6 mm, the taper variable in the width adjustment process is 6 mm, the casting speed is 1.0 m / min, the mold height is 900 mm, and the meniscus height is 800 mm. When the width adjustment process is caused by taper adjustment The upper cylinder is faulty, and the taper has been adjusted by 2 mm at this time, and the corresponding relationship between acceleration and taper change time during the taper change process is obtained.

[0050] From the above analysis, it can be seen that the fault in the width adjustment process occurs in the taper adjustment process. The relevant parameters in the process of width adjustment can be set as:

[0051] tanα=6 / 900, tanθ=(6-6) / 900, V c =1000 mm / min, l =800 mm, ΔL / = 2 mm

[0052] therefore:

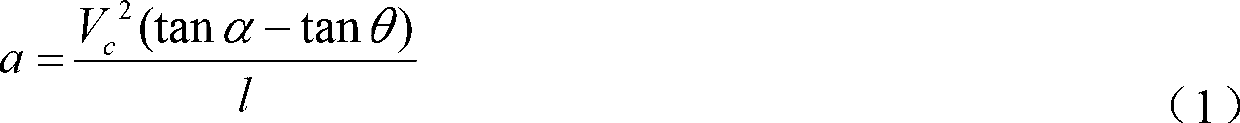

[0053] 1. Taper change acceleration:

[0054] (1)

[0055] 2. Taper change process time:

[0056] (2)

[0057] In the process of changing the taper i...

Embodiment 2

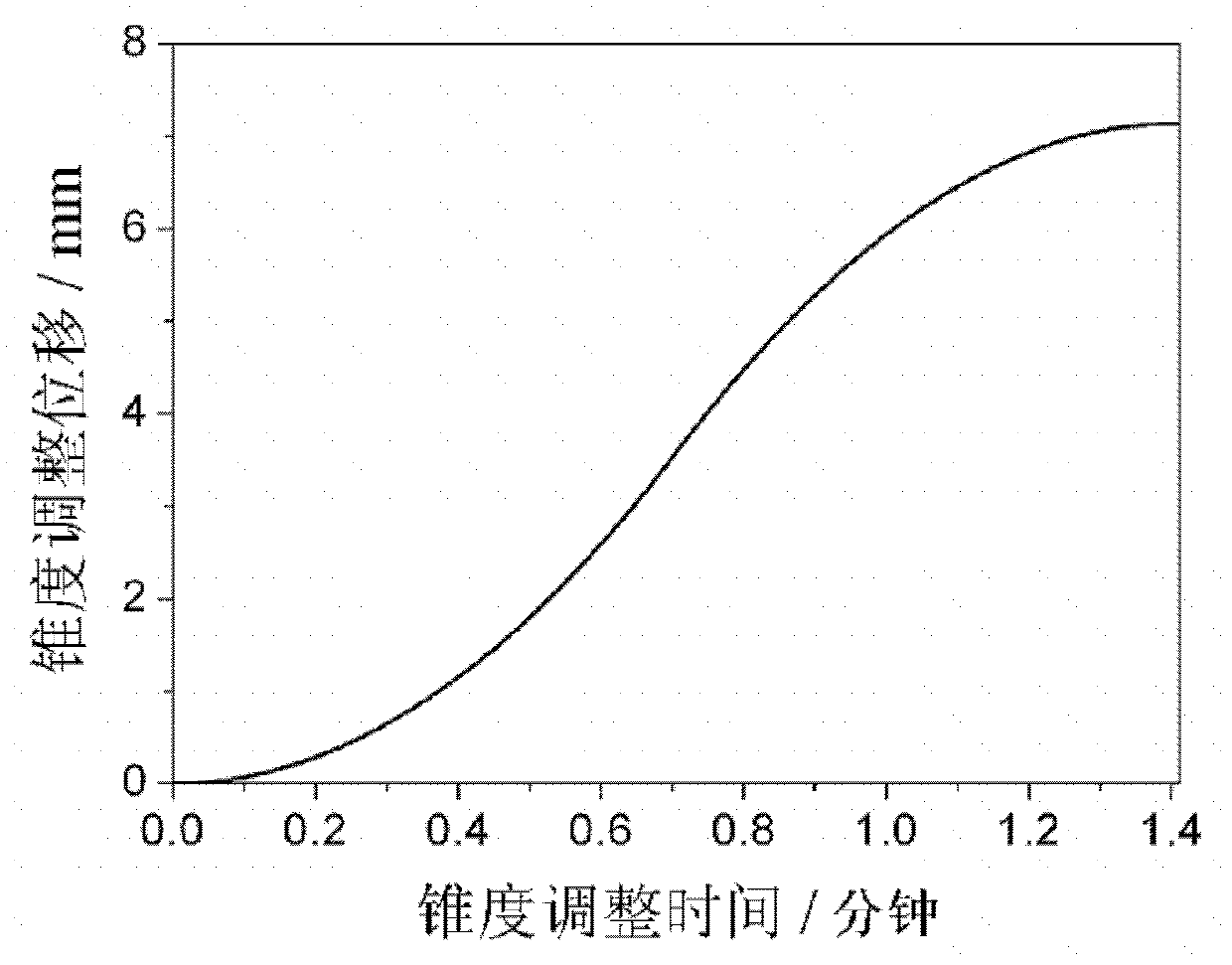

[0061] The taper on one side of the mold is 9 mm, the taper change during the width adjustment process is 7.2 mm, the casting speed is 1.2 m / min, the mold height is 900 mm, and the meniscus height is 800 mm. The failure of the upper cylinder is caused, and the corresponding relationship between acceleration and taper change time during the taper change process is obtained.

[0062] From the above analysis, it can be seen that the fault in the width adjustment process occurs in the width adjustment translation process. The relevant parameters in the process of width adjustment can be set as:

[0063] tanα=9 / 900, tanθ=(9-7.2) / 900, V c =1200 mm / min, l =800 mm, ΔL / = 7.2 mm

[0064] therefore:

[0065] 1. Taper change acceleration:

[0066] (3)

[0067] 2. Taper change process time:

[0068] (4)

[0069] In the process of changing the taper in Example 2, the time displacement relationship corresponding to the upper mouth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com