Test device and test method for simulating molten iron flow at furnace bottom of blast-furnace hearth

An experimental device, blast furnace technology, applied in fluid dynamics tests, blast furnaces, measuring devices, etc., can solve problems such as large workload and experimental costs, repeated research resources, and difficulty in analyzing the reasons, and reduce material consumption and labor. Strength, improving work efficiency, and saving experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

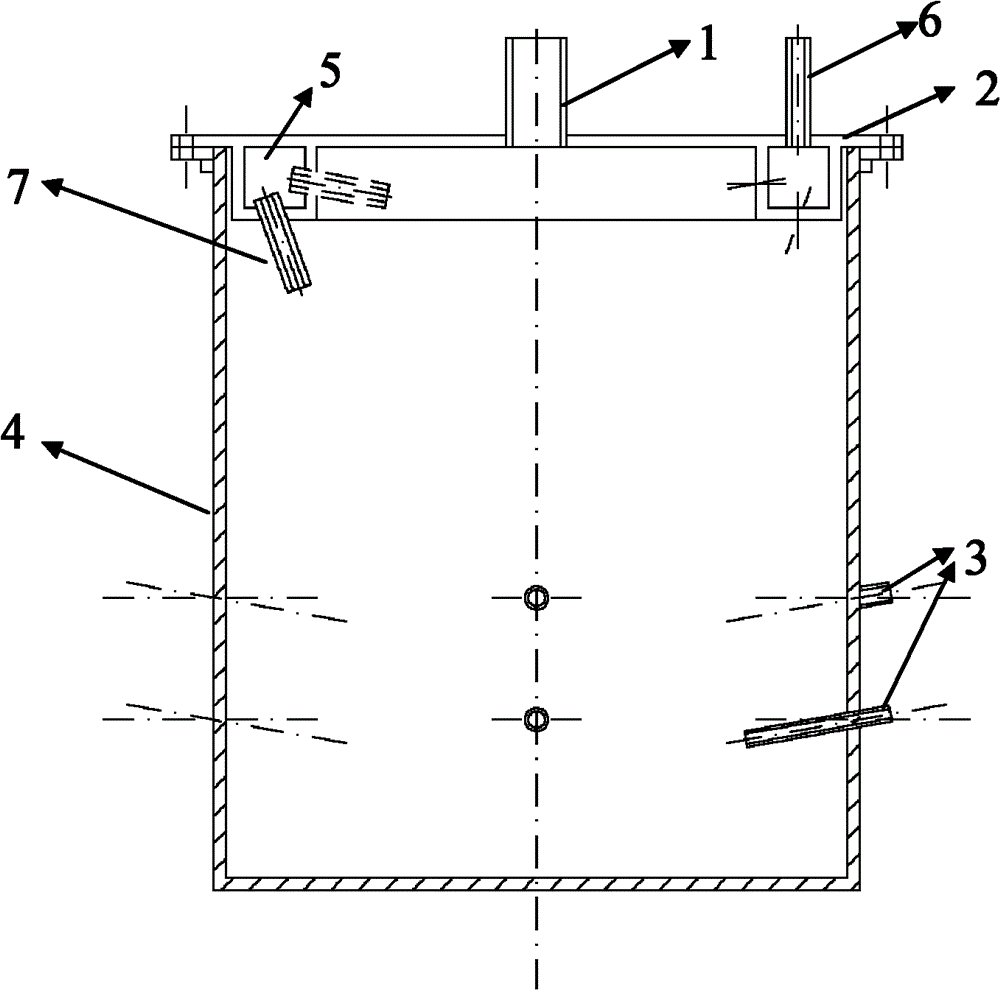

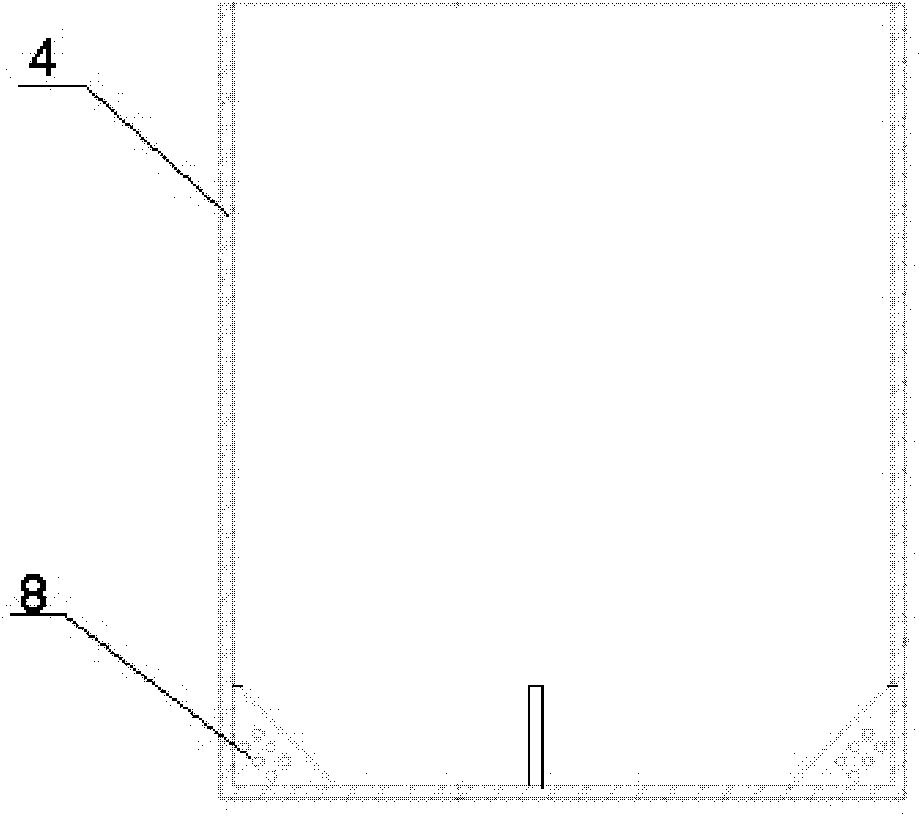

[0049] An experimental device for simulating the flow of molten iron at the bottom of the hearth of a blast furnace, comprising a cylindrical transparent container, a sealing cover, an air dispersing hole, a cold air surrounding pipe and a water discharge port. The sealing cover is covered on the upper end of the cylindrical transparent container , The diameter of the sealing cover is adapted to the inner diameter of the cylindrical transparent container; the air dispersing hole is arranged on the sealing cover; the lower surface of the sealing cover is provided with a cold air enclosure tube, and the surrounding diameter of the cold air enclosure tube is The inner diameter of the cylindrical transparent container is adapted; a cold air inlet is provided on the upper surface of the sealing cover, and the cold air inlet is connected to the cold air surrounding pipe; the cold air surrounding pipe is evenly provided with a plurality of air outlets, and the air outlets face the cylin...

Embodiment 2

[0056] The method of using the experimental device described in Example 1 to simulate the flow state of molten iron at the hearth of a blast furnace is as follows:

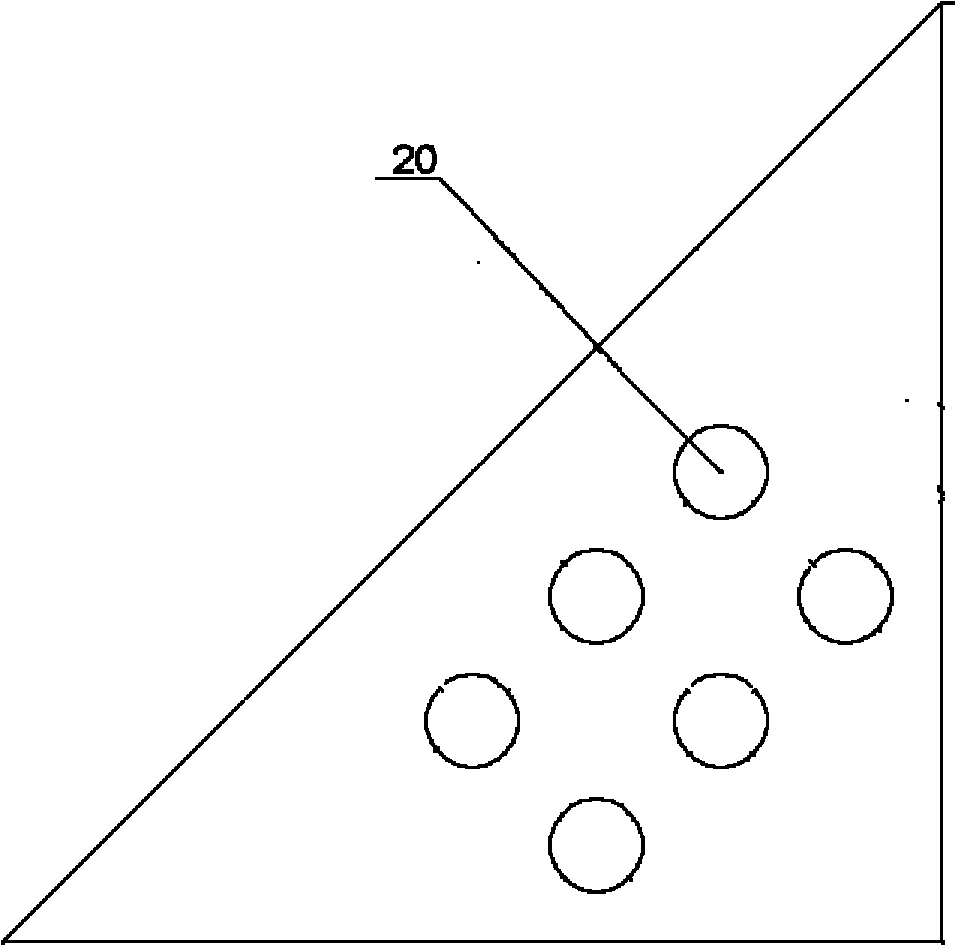

[0057] 1) Put the simulated dead material column into a cylindrical transparent container, and adjust the maximum diameter of the simulated dead material column to 400~450mm;

[0058] 2) Inject water into the cylindrical transparent container through the air vent hole. When the height of the water injection reaches 300mm, open the lower drain and adjust the water injection flow to make the liquid level constant at 300mm. Adjust the floating height of the simulated dead material column to make the simulation dead. The bottom of the material column is 100mm from the bottom of the container;

[0059] 3) Turn on the laser Doppler velocimeter and adjust the measurement position so that the lens of the laser Doppler velocimeter is at the level of the upper drain hole, and the lens plane is parallel to the longitudinal section ...

Embodiment 3

[0065] As in the method described in embodiment 2, the difference is that the step 1) adjusts the maximum diameter of the simulated dead material column to 300-350 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com