Continuous casting roughing slag inspection method and device based on vibration monitoring

A technology of vibration monitoring and detection methods, which is applied in the configuration of indicating equipment/measuring equipment, measuring devices, casting equipment, etc., and can solve the problems of small vibration of mechanical operating arms, difficulty in distinguishing the moment of slag dropping manually, and swirling molten steel, etc. problem, to avoid misjudgment and missed judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

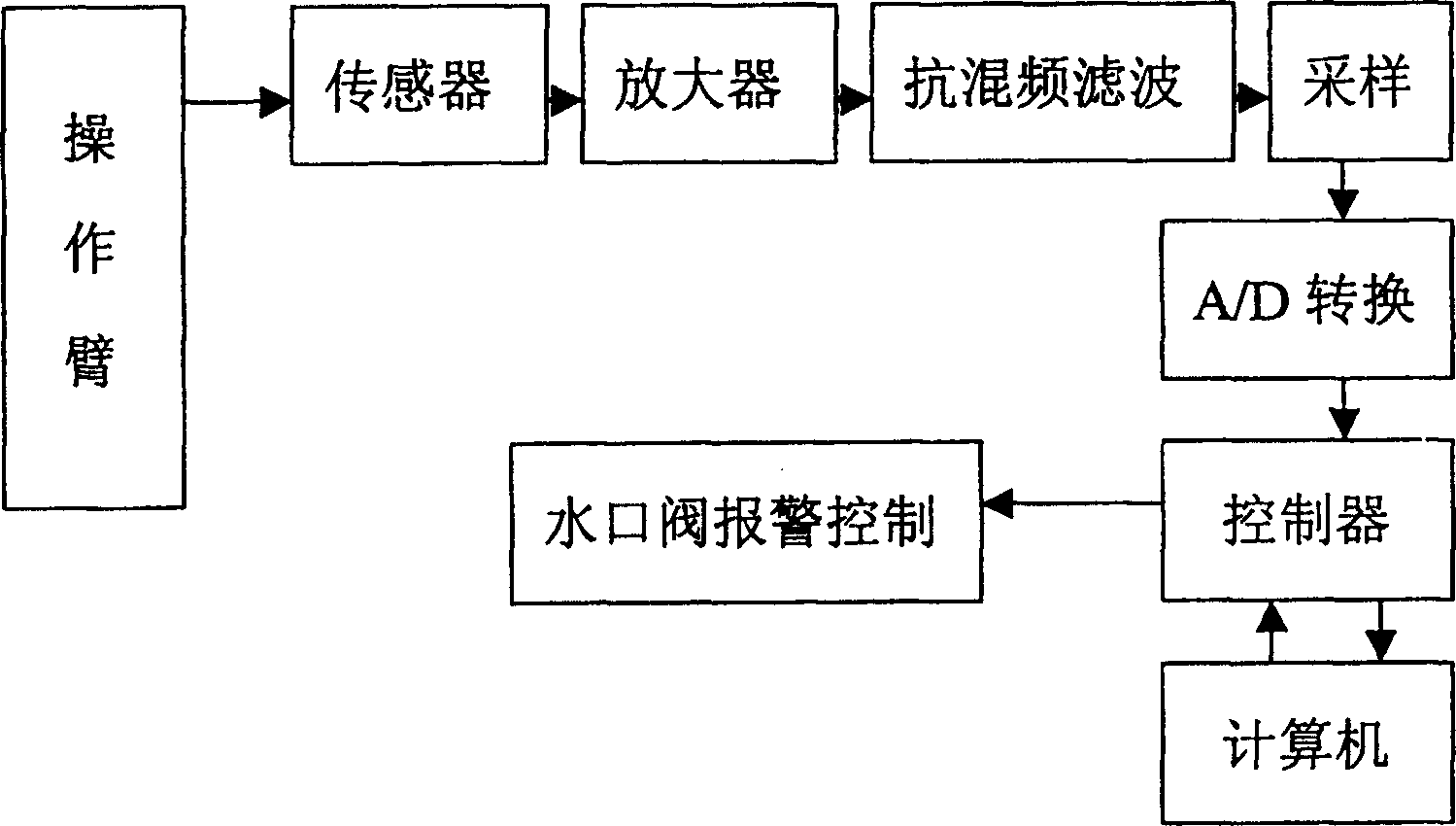

[0041] The hardware composition of the system

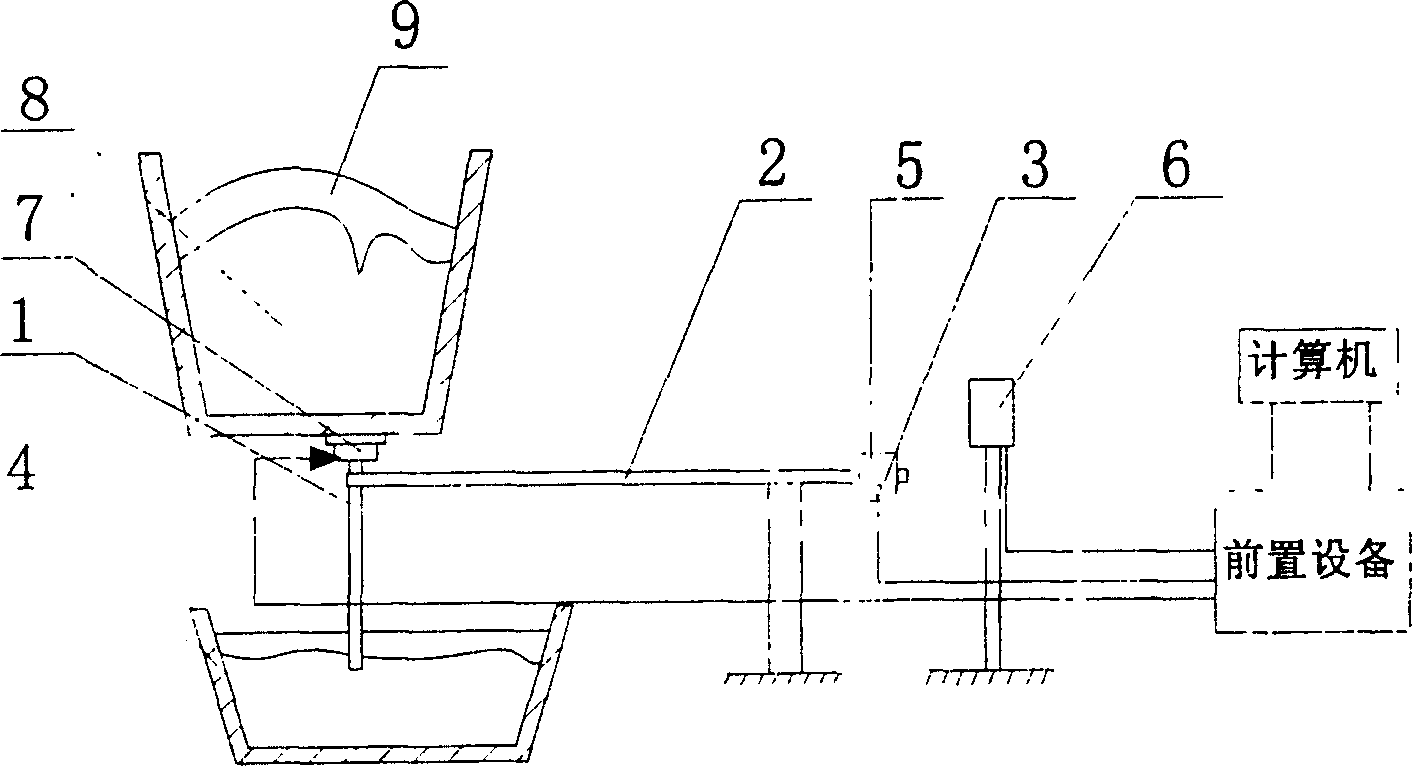

[0042] The device of the present invention mainly includes the following parts: computer and control equipment, signal sensing and acquisition equipment, display and alarm equipment, and also includes auxiliary equipment such as intermediate terminal boxes and switch boxes.

[0043] The computer and control equipment is an indoor control cabinet, which is mainly composed of a display, an operating console, and a pre-processor. It mainly completes the collection and processing of signals, and completes the control of display and alarm equipment.

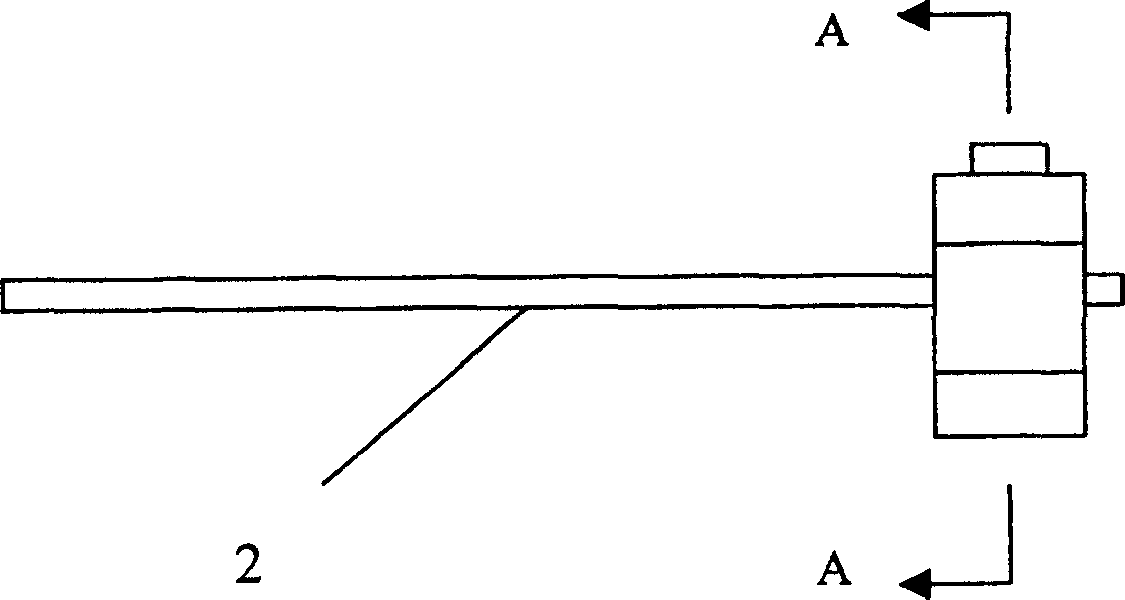

[0044] The signal sensing and acquisition equipment adopts a piezoelectric acceleration sensor integrated with an amplifier circuit inside. The end of the operating arm 2 away from the shroud 1 is fixedly connected to the sensor bracket 5, and the sensor bracket 5 in di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com