Lander-soil interaction impact model test device

A technology of impact model and test device, applied in measurement devices, instruments, force/torque/work measuring instruments, etc., can solve problems such as seldom considering real-time mechanical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

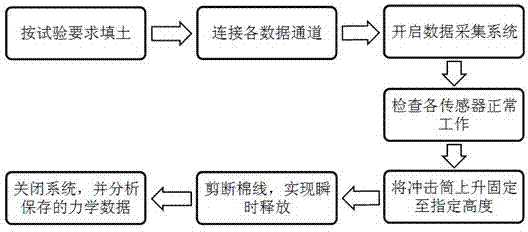

[0013] The purpose and effects of the present invention will become more apparent by referring to the accompanying drawings in detail of the present invention.

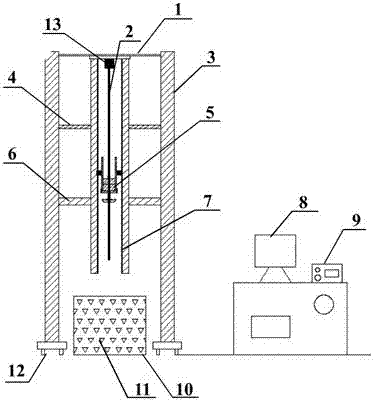

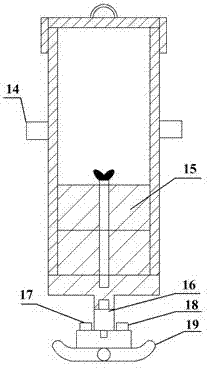

[0014] Such as figure 1 As shown, the lander and soil interaction impact model test device of the present invention includes: beam 1, cotton thread 2, side column 3, upper beam support 4, impact cylinder 5, lower beam support 6, sliding guide rail 7, computer 8, signal Processor 9, soil tank 10, moving slide rail 12, displacement meter 13.

[0015] Among them, the beam 1 and the moving slide rail 12 are respectively fixed on the top and bottom of the side column 3, the frame of the overall test device is fixed by the beam 1 and the side column 3, and the overall axial movement can be made by moving the slide rail 12, and the primary filling can be carried out by moving The device measures multiple sets of trials. A displacement gauge 13 is fixed at the center of the lower beam 1 , and the upper and lower beam suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com