Single excitation longitudinal-torsional compound vibration conversion device

A technology of compound vibration and conversion device, applied in the direction of fluid using vibration, etc., can solve the problems of limited transducer power capacity, imperfect design theory, and difficulty in excitation at the same frequency, and achieve simple structure, easy popularization and application, and market promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

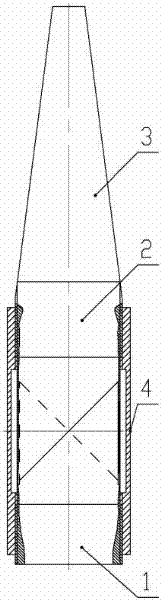

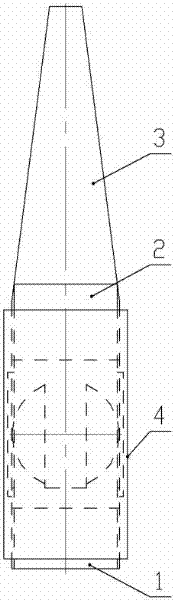

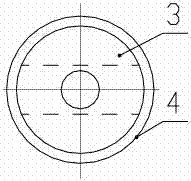

[0017] like Figure 1 ~ Figure 4 As shown, the single-excitation longitudinal-torsional compound vibration conversion device of the present invention includes a first converter 1 and a second converter 2, both of which are cylinders, and one end of the first converter 1 and one end of the second converter 2 are connected by a tenon The 90 structure is press-fitted, and an axial fixing mechanism is provided between the first converter 1 and the second converter 1 . The other end of the second converter 2 is connected with a conical horn 3 , of course, the horn 3 can also be of a conventional structure such as a ladder shape, a catenary shape, or an exponential shape. The axial fixing mechanism is a threaded sleeve 4 which is threadedly connected with the first converter 1 and the second converter 2 respectively, and the two sides of the inner wall of the threaded sleeve 4 are respectively screwed with the first converter 1 and the second converter 2 The direction of rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com