Ultrasonic-assisted high pressure eliminating device for glue scales of packaging machine

An ultrasonic-assisted and clearing device technology, which is applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of long time-consuming glue scraping, uneven scraping, and serious adhesion of glue stains, etc. Achieve the effect of reducing difficulty, reducing labor intensity and facilitating removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

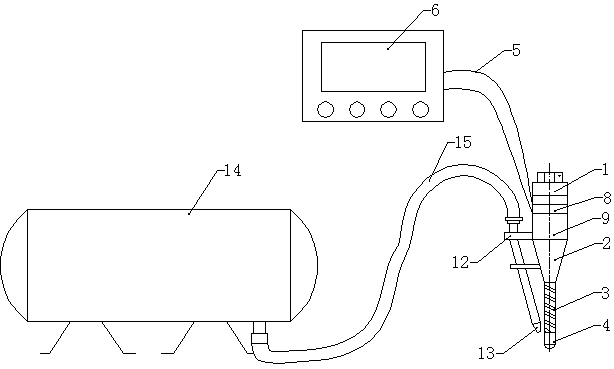

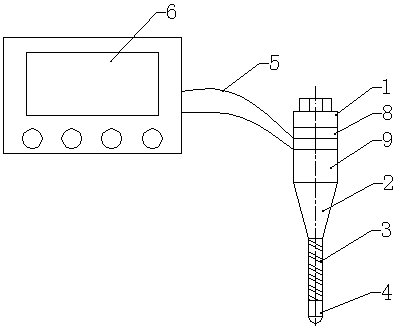

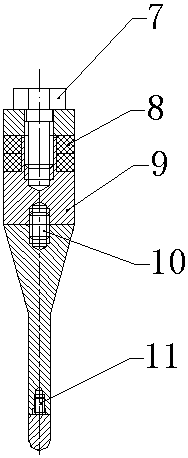

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1 to Figure 3 As shown, a packaging machine glue scale ultrasonic-assisted high-pressure removal device of the present invention includes a multifunctional ultrasonic vibration glue clearing mechanism and a high-pressure water glue clearing mechanism. The multifunctional ultrasonic vibration glue clearing mechanism includes an ultrasonic vibrator for generating acoustic vibrations, The ultrasonic vibrator is composed of an ultrasonic transducer and an ultrasonic horn 2 , and the ultrasonic vibrator is electrically connected with an external ultrasonic generator 6 through a wire 5 . The end of the ultrasonic horn 2 is fixedly installed with a working head 4 for clearing glue through a detachable type. In this embodiment, the working head 4 is a ball head, which can also be a working device such as a spatula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com