Working component capable of being fit with various shaft ends

A technology of working components and shaft ends, which is applied in the field of working components, can solve the problems of lack of versatility, failure to install multi-function tools, and non-universal working components, etc., and achieve the effect of reducing accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

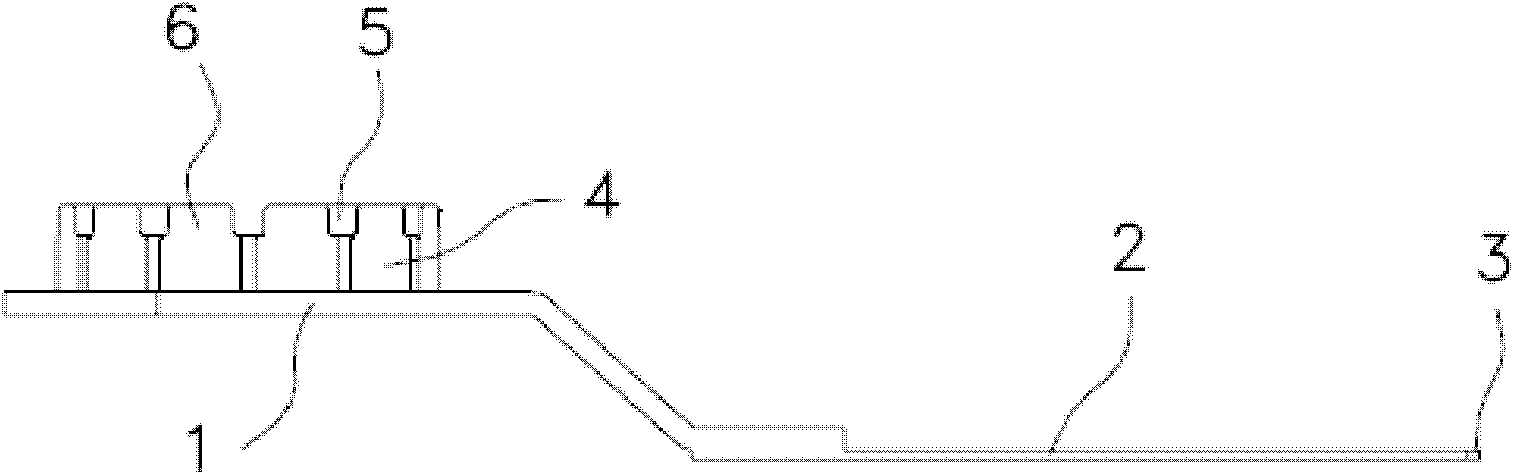

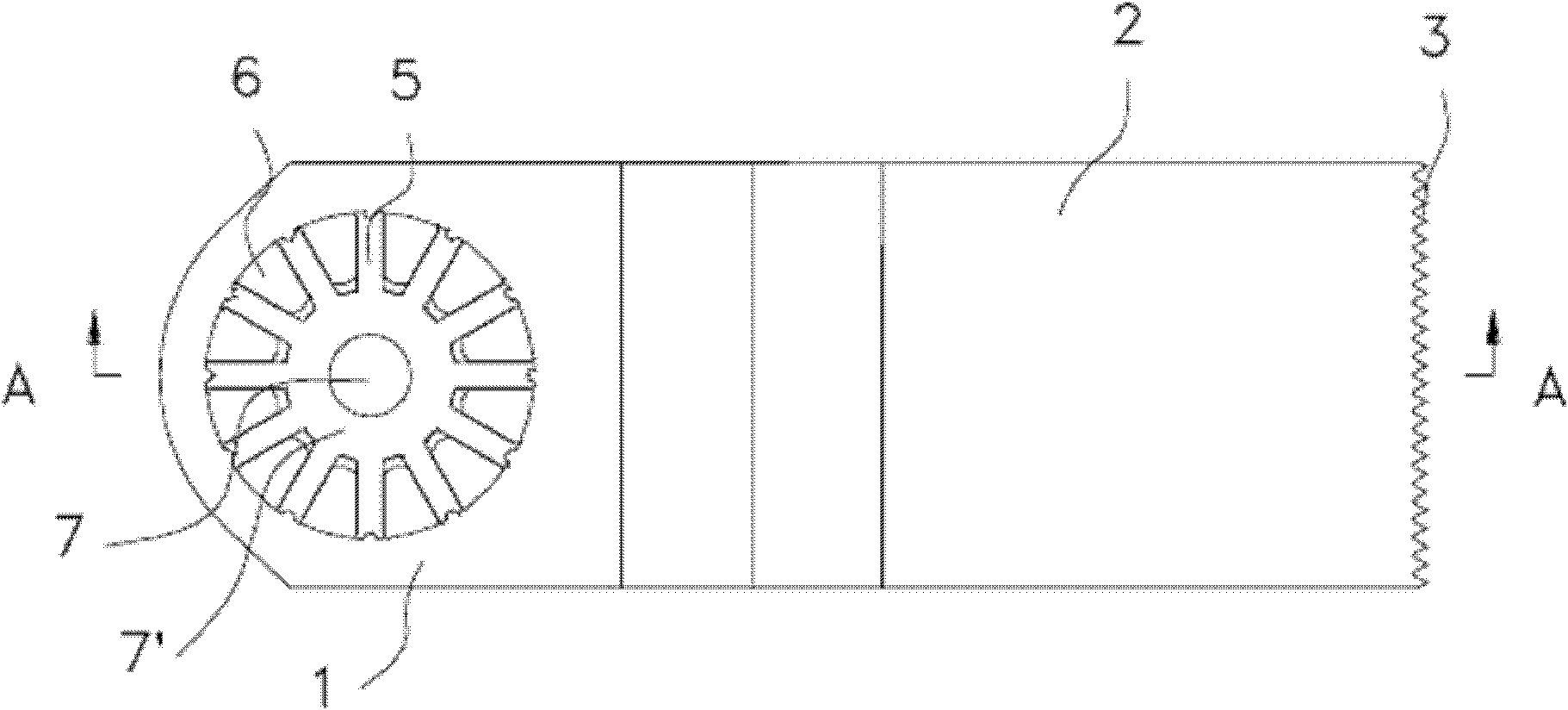

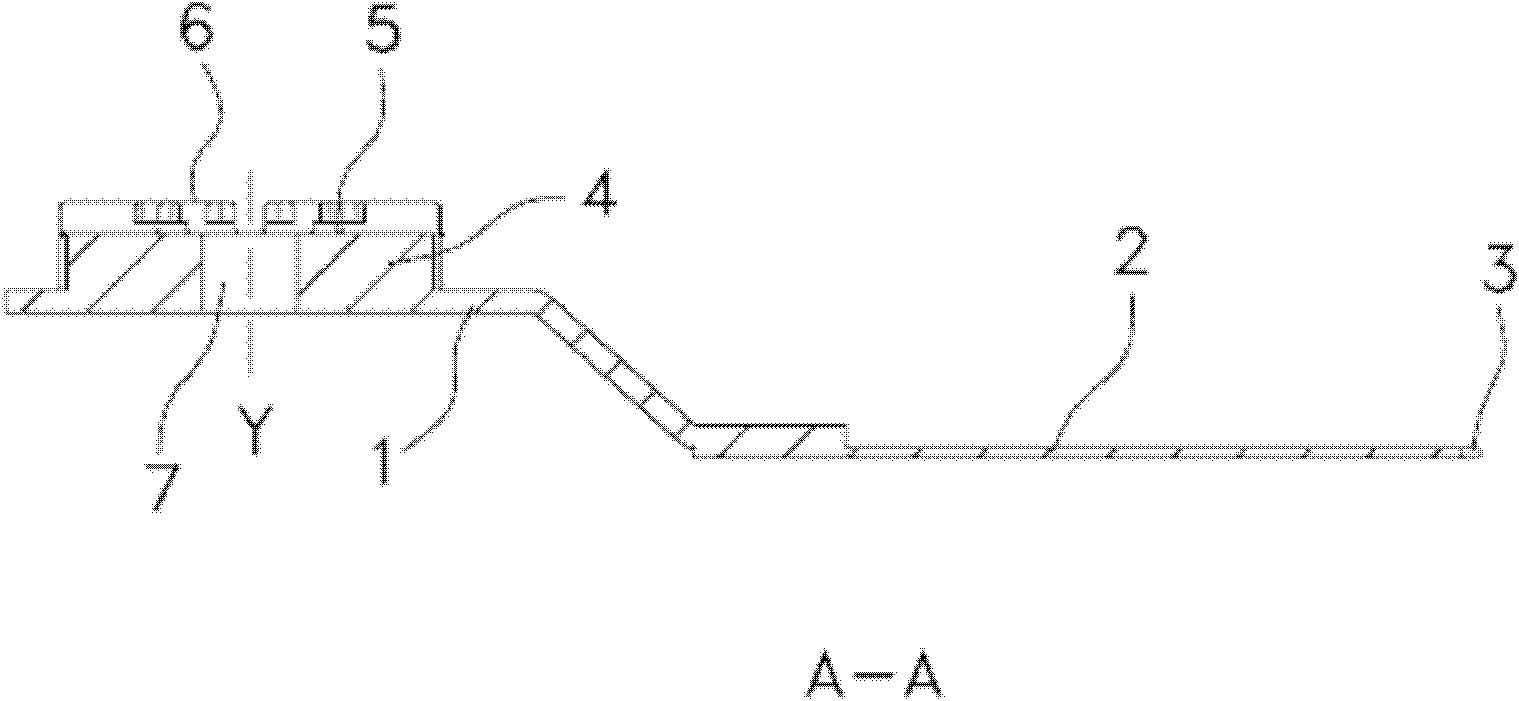

[0035] Such as Figure 1 to Figure 3 As shown, it is the first embodiment of the working element of the present invention that can be adapted to various shaft ends. The working element is a saw blade commonly used on multi-function tools as an example. The saw blade includes a body part 2 and a body part 2 The connecting part 1 is used to be adapted to the shaft end of the multi-function tool. The front end of the body part 2 is a sawtooth area 3 acting on the workpiece to be processed. A mounting hole 7 is provided on the connecting part 1. The mounting hole 7 has a longitudinal axis 8. The radial direction of the mounting hole 7 is perpendicular to the longitudinal axis 8 . The connecting part 1 of the saw blade is provided with an adapter part 4, and the adapter part 4 is fixedly connected to the connecting part 1 by means of welding, riveting or screws. Of course, the adapter part 4 and the connecting part 1 can also be integrally formed. . The fitting part 4 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com