A combined ladder formwork

A combined and stepped technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of troublesome cleaning, long construction period, and large loss of cement slurry, so as to avoid environmental pollution , Low processing cost and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

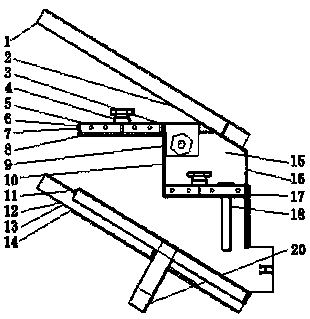

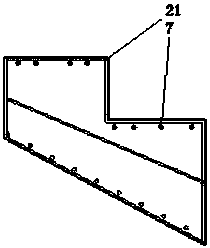

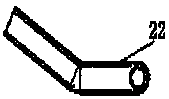

[0028] Such as Figure 1-3 As shown, the present invention provides a combined ladder formwork, which is a mold assembly with two steps surrounded by six main formworks. Welding reinforcement slats 6, bolt holes 7 for installing the side main formwork are processed on the front and back slats of the upper step and the lower step, and welded at the intersection of the middle slats on the main formwork of the upper step. The tubular sleeve 4 that mold is used is processed with the bolt 9 through holes that fix the upper main formwork on the left side of the middle slat of the lower step, and a square plate 3 with holes is fixed with bolt 9 on the side of this through hole. The left end is welded with the slat 6 of the upper main template, and the right end of the middle slat 6 of the lower step is welded with an oblique guide tube 2, the left half of the guide tube 2 is tightly mounted on the guide rod 1, and the right half of the guide tube 2 slides Install the bent bar 22 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com