A hydraulic lifting tower

A technology of hydraulic lifting and tower body, applied in the field of communication lifting tower, can solve the problems of troublesome removal, danger, troublesome installation, etc., and achieve the effect of small construction amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

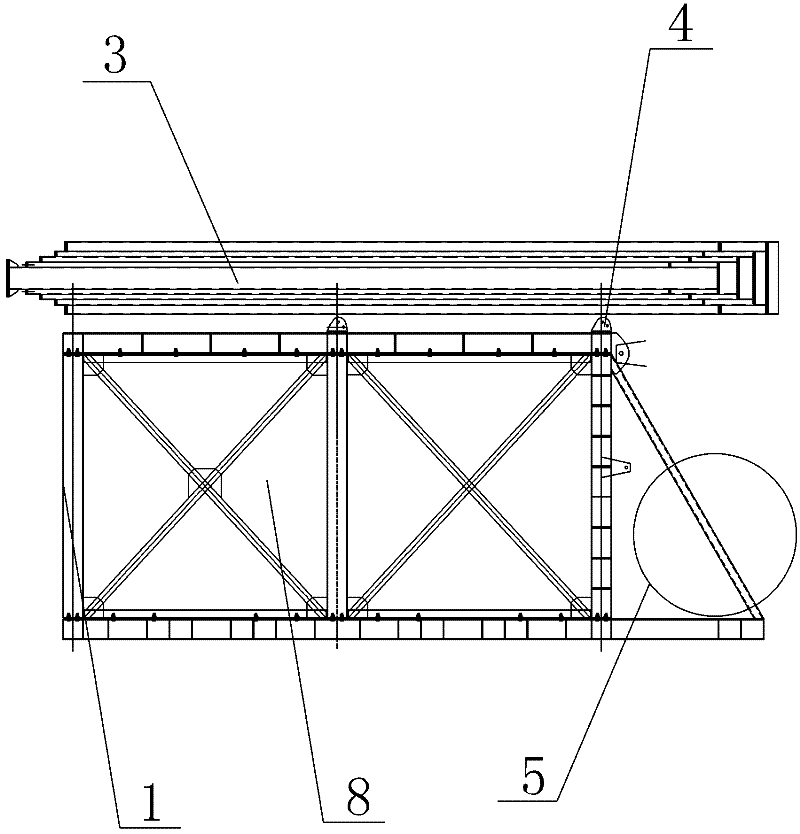

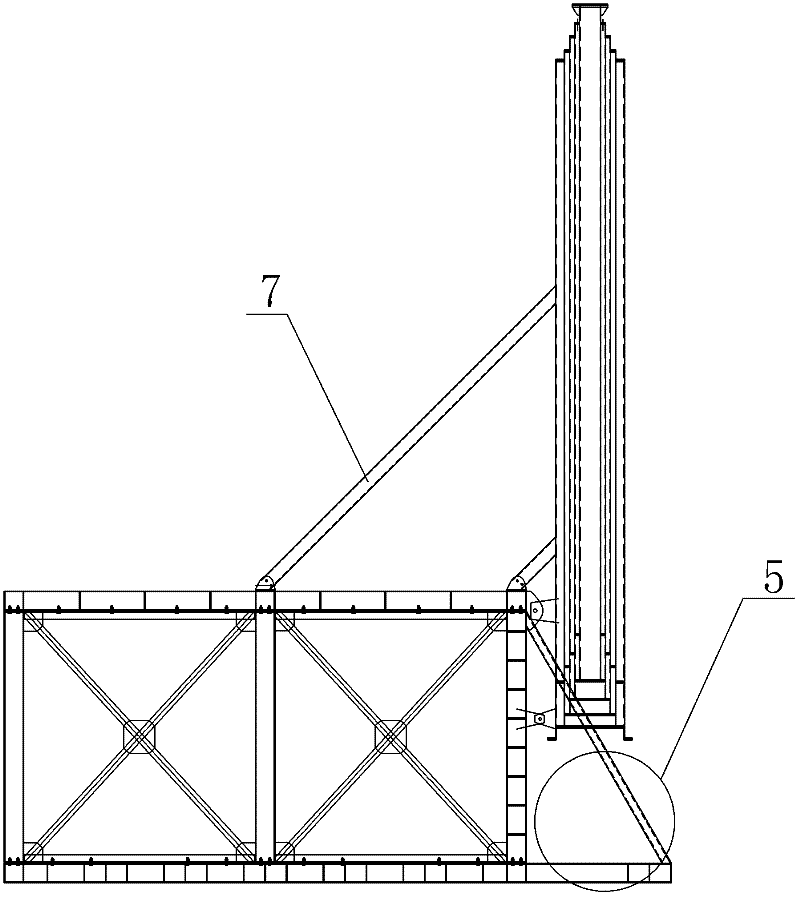

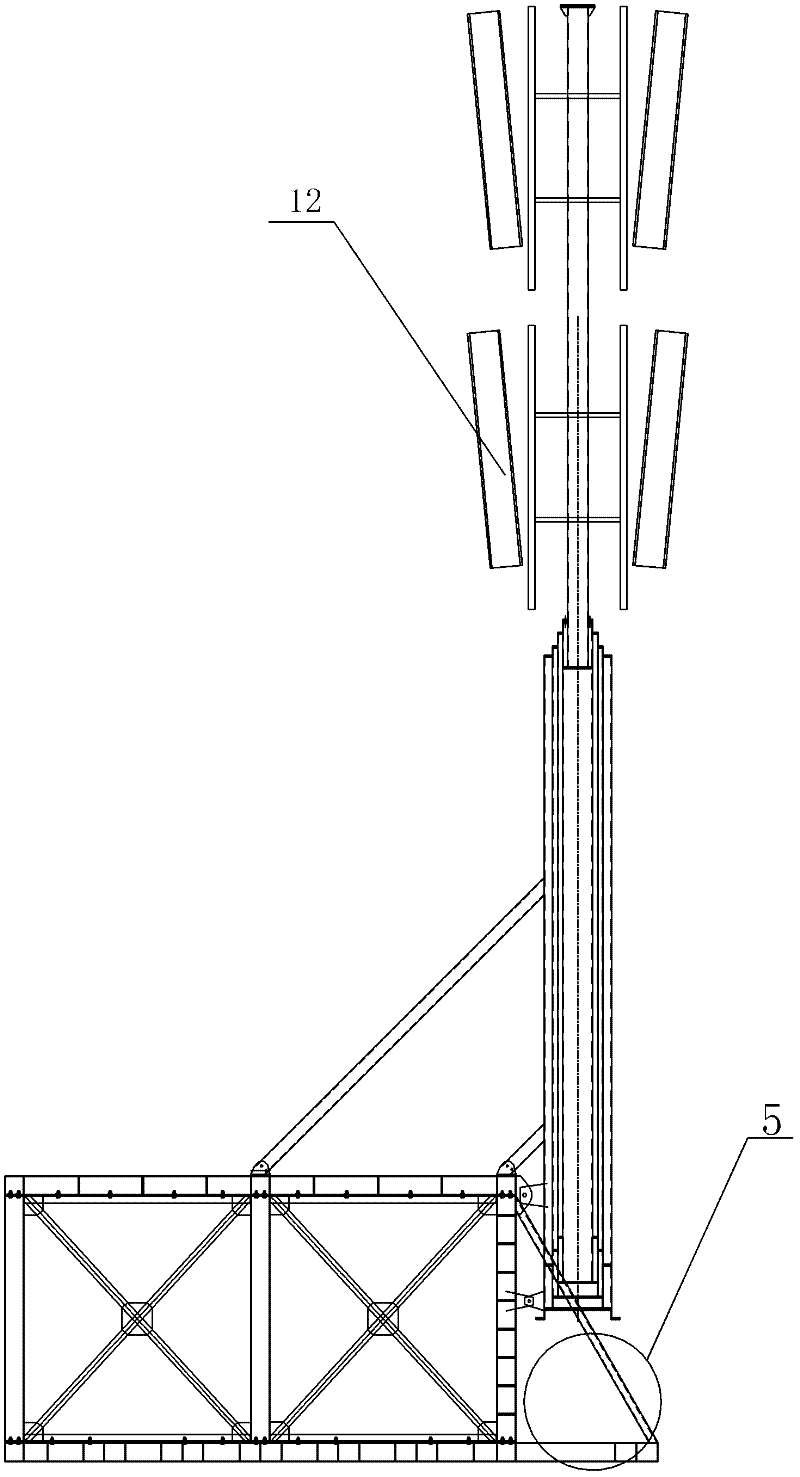

[0012] Such as Figure 1-3 , a hydraulic lifting tower, comprising a steel frame 1, the steel frame 1 is provided with a multi-section tower body 3, the tower body 3 and the steel frame 1 are flexibly connected by bolts 4, and the tower body is provided with sleeves The tubular hydraulic jack 5 and the casing hydraulic jack 5 drive the tower body 3 to lift.

[0013] After the tower body rises, each section of the tower body is fixed by pins 6. A machine room 8 is arranged on the steel frame 1 .

[0014] Such as Figure 4 , the tower body 3 of the lifting tower is a multi-section tower body. Before the tower body is raised up, the tower bodies of each section are socketed together, and the bottom section of the tower body is connected to the steel frame by bolts 4. The tower body is placed horizontally on the steel frame. When the tower body needs to be raised up, the tower body is rotated along the steel frame through the hinged bolts 4, and finally stands upright. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com