Equipment with slot nozzles for vertical jets for the treatment of granular materials

A technology for processing particles and slit nozzles, which can be applied to spray devices, spray devices, liquid spray devices, etc., and can solve problems such as difficulty in adapting to different characteristics of different liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

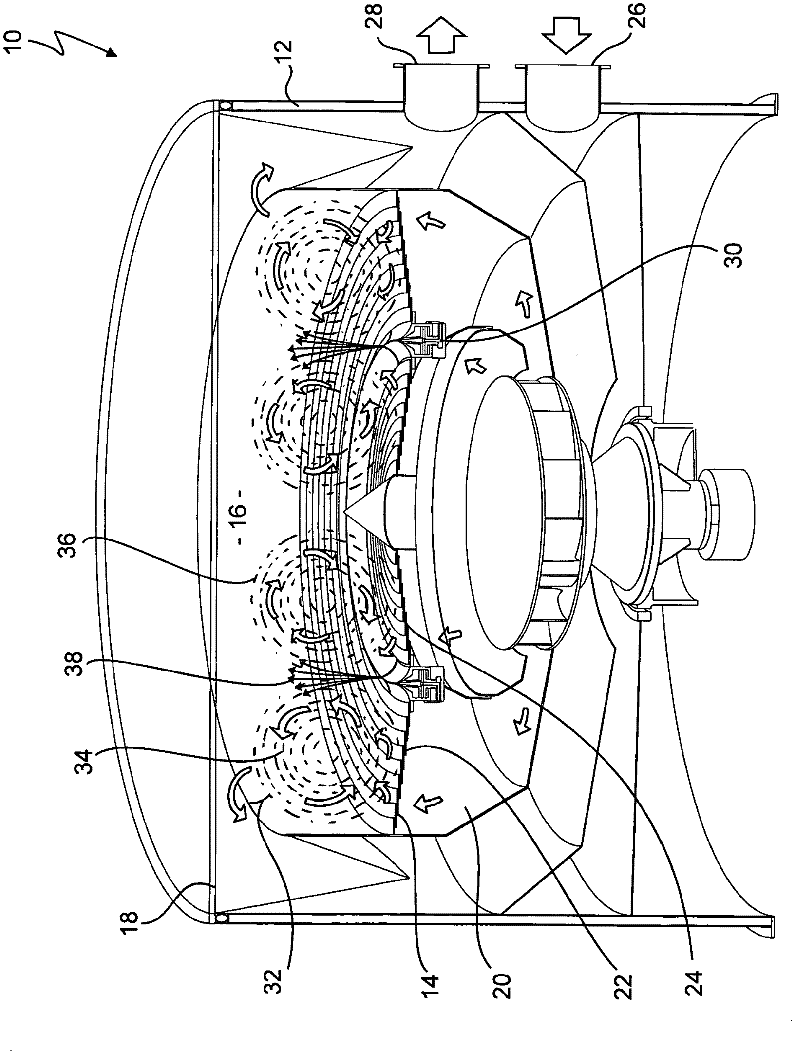

[0085] exist figure 1 The apparatus for processing granular material shown in , is indicated in its entirety by the reference numeral 10 .

[0086] The device 10 has an upright cylindrical container 12 with a base 14 at an intermediate height. The interior of the container 12 represents the process chamber 16 . The process chamber 16 is closed at the upper end by a cover 18 . An inflow chamber 20 is formed below the bottom surface 14 .

[0087] The bottom surface 14 is composed of a first group 22 of annular metal plates arranged on the outside on the circumference and stacked one above the other. A ring-shaped metal plate in such a way that two ring-shaped metal plates overlap each other. As a result, an approximately horizontally oriented annular gap is formed between the two annular metal plates arranged one above the other. Furthermore, there is an inner ring-shaped sheet metal pack 24 , wherein the ring-shaped metal plates are arranged in such a way that the inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com