Lighting system for three-dimensional printing equipment

A technology of lighting system and support body, applied in the field of lighting system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

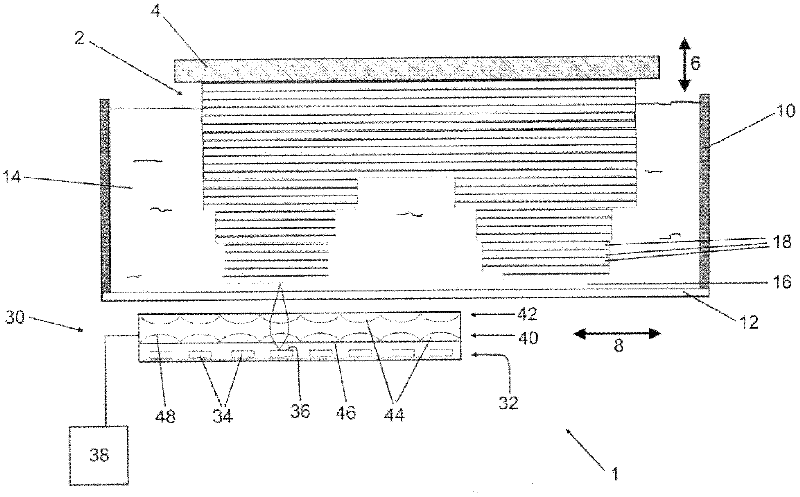

[0045] see first figure 1 , figure 1 is a cutaway side view of an exemplary stereoscopic printing apparatus (SLA) 1 in which the lighting system according to the present invention may be used. This SLA1 can be used to produce a tangible object 2, such as a prototype or model of an article, layer by layer. The SLA1 comprises a carrier plate 4 , a reservoir 10 and a lighting system 30 .

[0046] During production, the tangible object 2 is suspended from a carrier plate 4 on which the first structural layer of the object 2 and indirectly any subsequent layers are glued. The carrier plate 4 is movable in direction 6 by a drive mechanism (not shown) and is moved up by the thickness of one layer each time a new layer is constructed.

[0047] The reservoir 10 contains a liquid photocurable resin 14 . The base plate 12 of the reservoir 10 is optically transparent to light emitted by an illumination system 30, which will be described later. The bottom plate 12 also serves as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com