Patents

Literature

103 results about "Volumetric printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volumetric printing is a three-dimensional digital-to-physical imaging technology developed in 2013 that uses ink or other pigments suspended in a volume to form a full-color volumetric scene in physical space. It is a static version of volumetric display. Volumetric prints are auto-stereoscopic, full parallax (in both horizontal and vertical viewing arrangements) and can be viewed by multiple viewers in regular room lighting. A volumetric print can be thought of as a reconstructed light field based on the scattering of light by distributed pigments in volume. Any three-dimensional scene can be volumetrically printed, although biological specimens and volumetrically X-rayed objects (i.e., CT scans) are thought to be particularly well suited to this type of imaging.

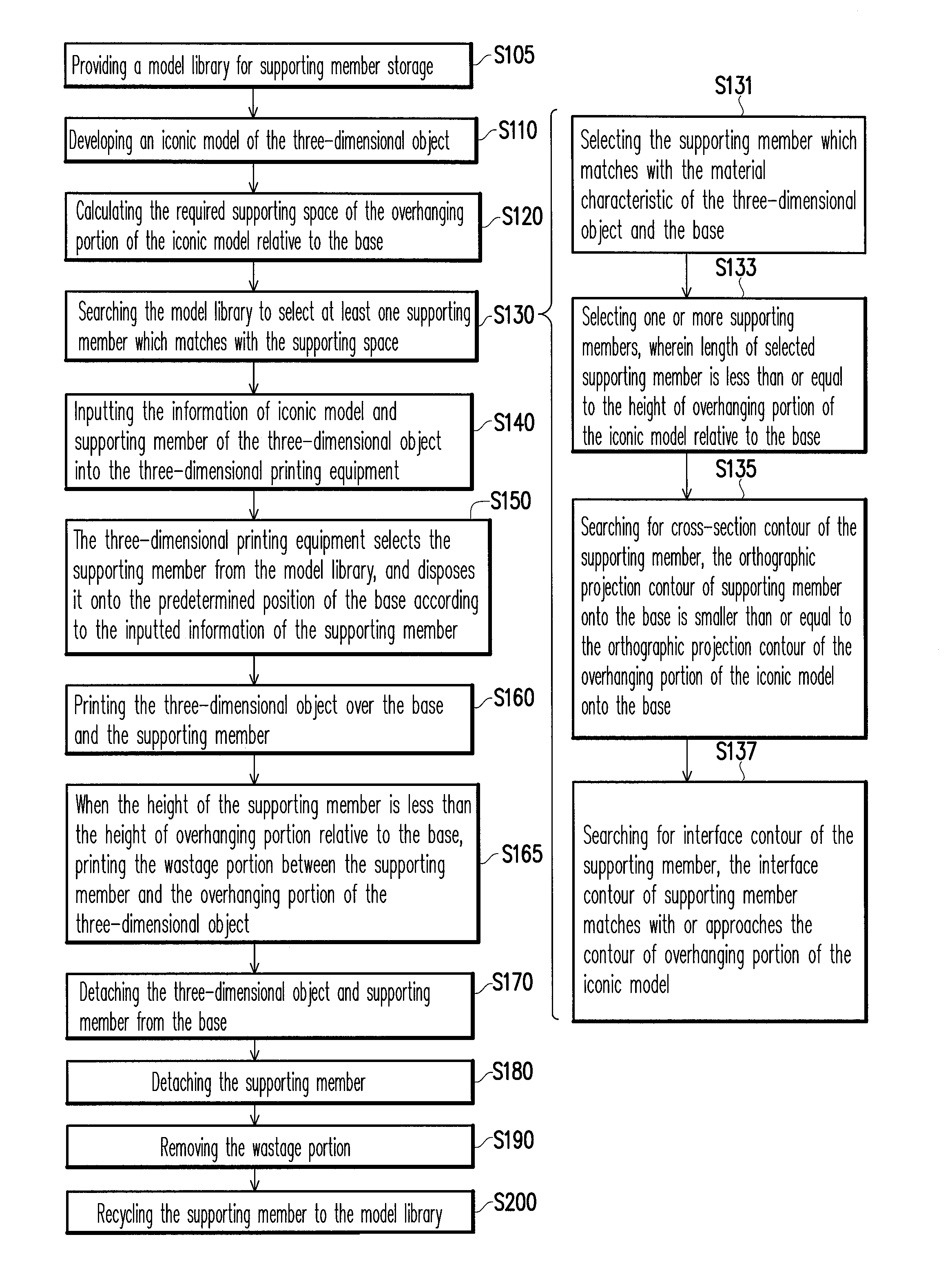

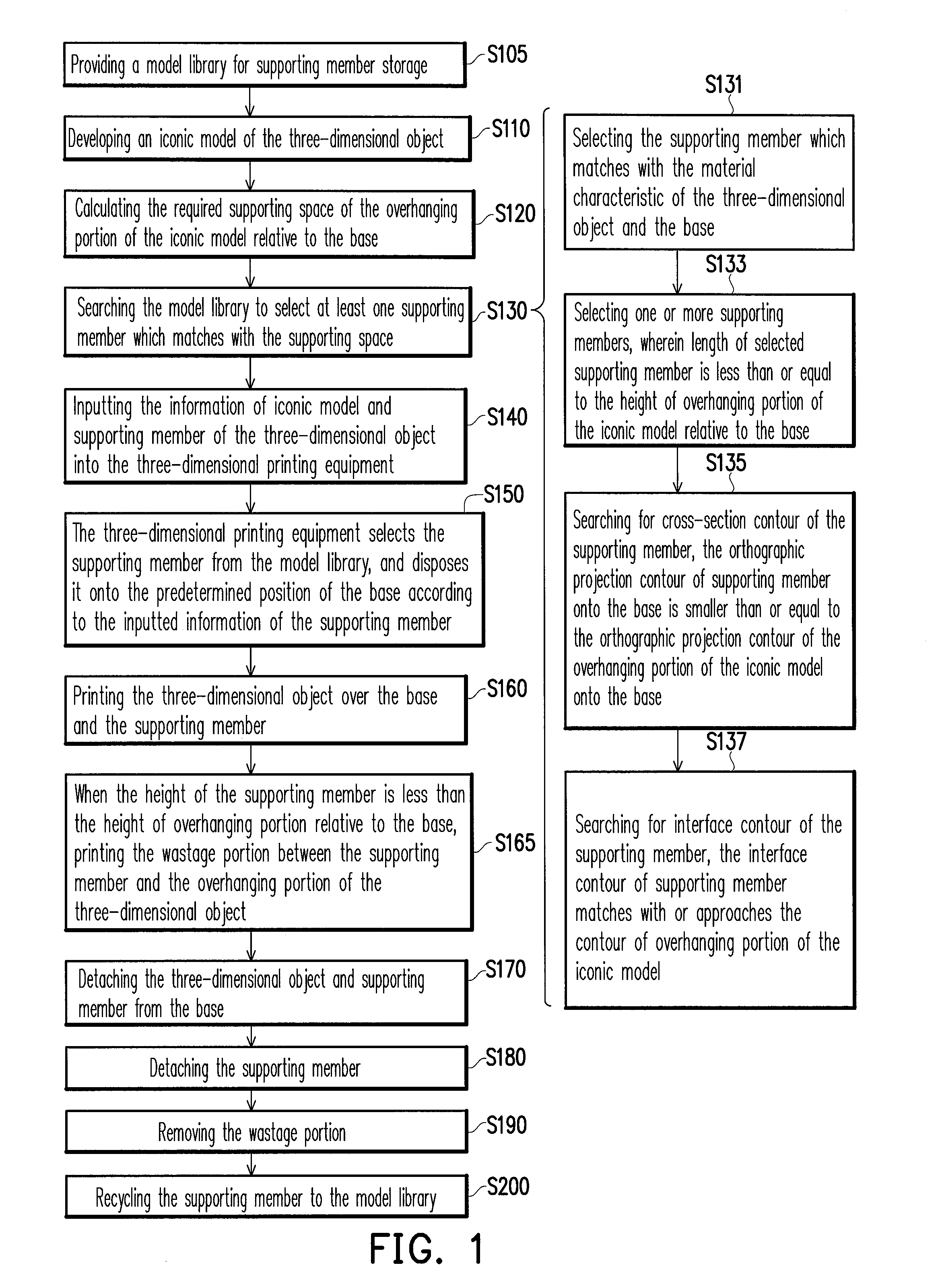

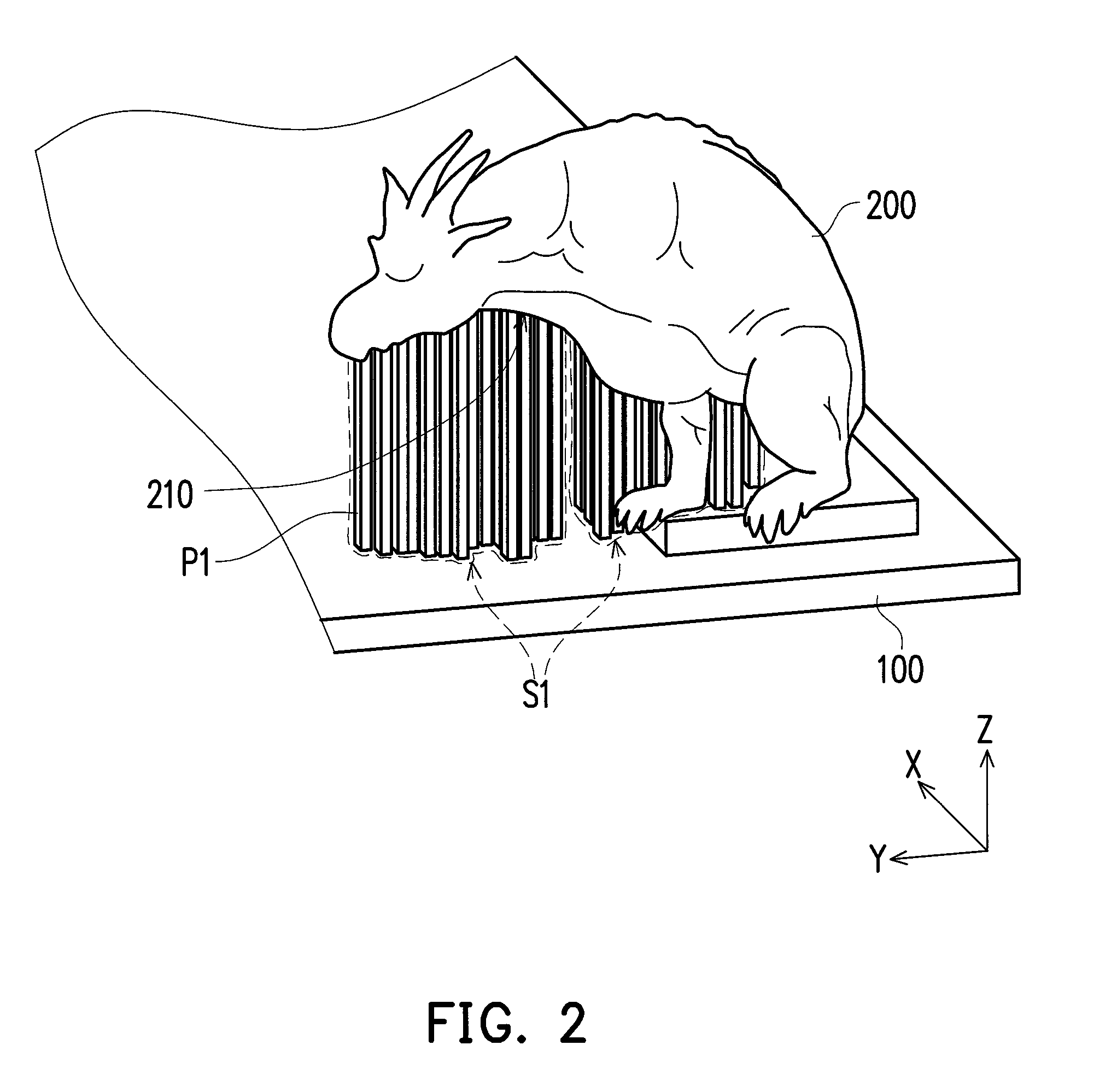

Three-dimensional printing method

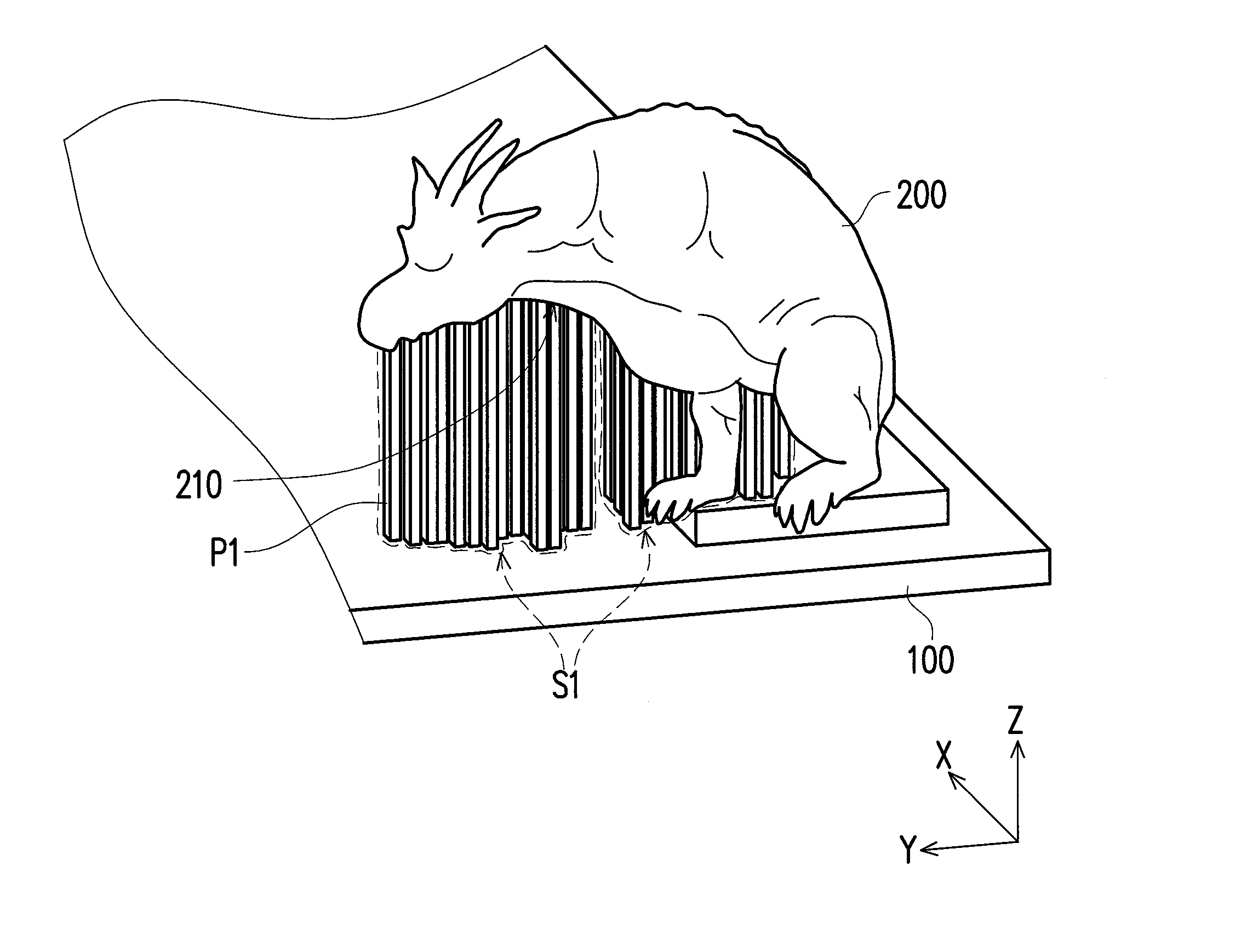

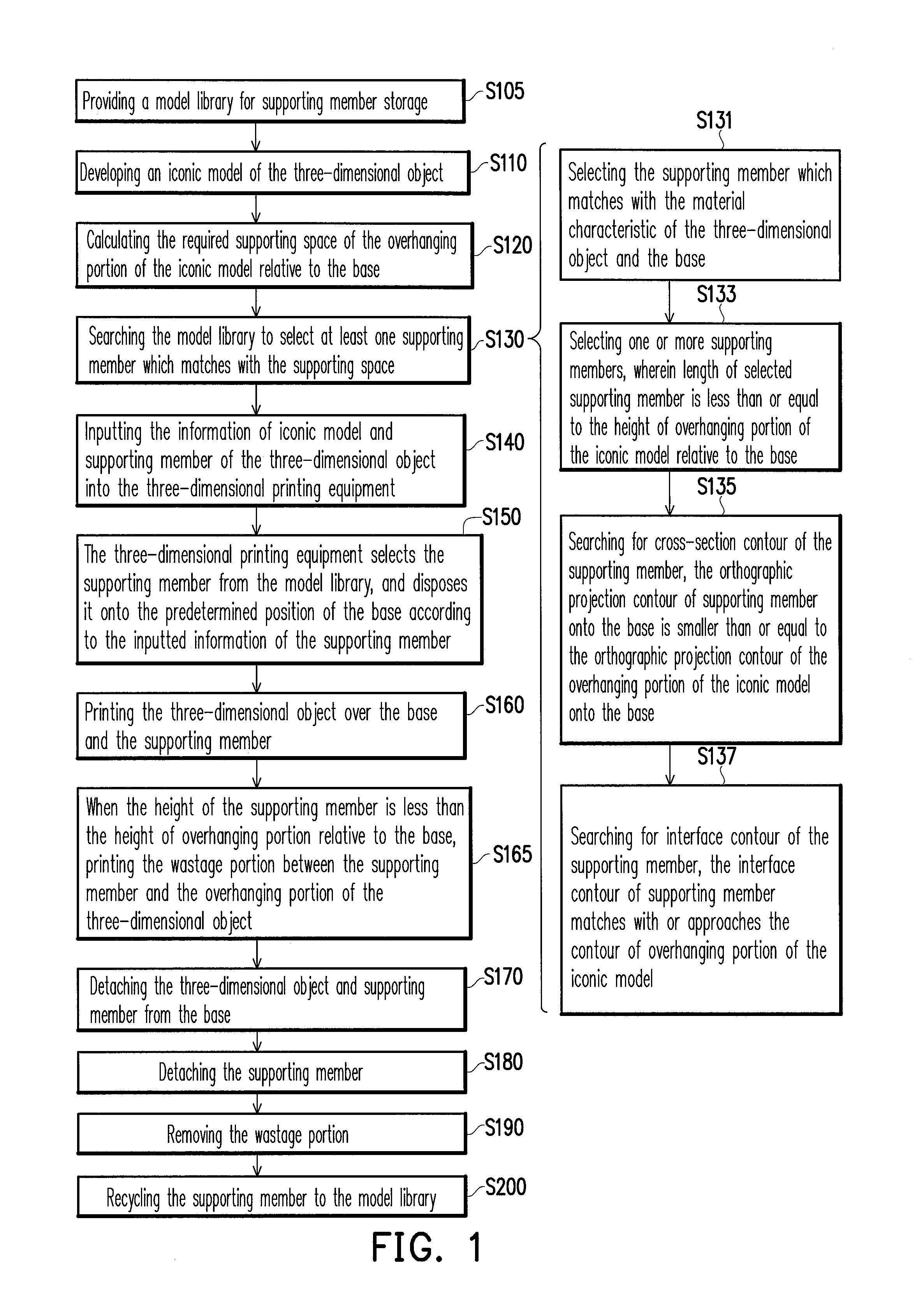

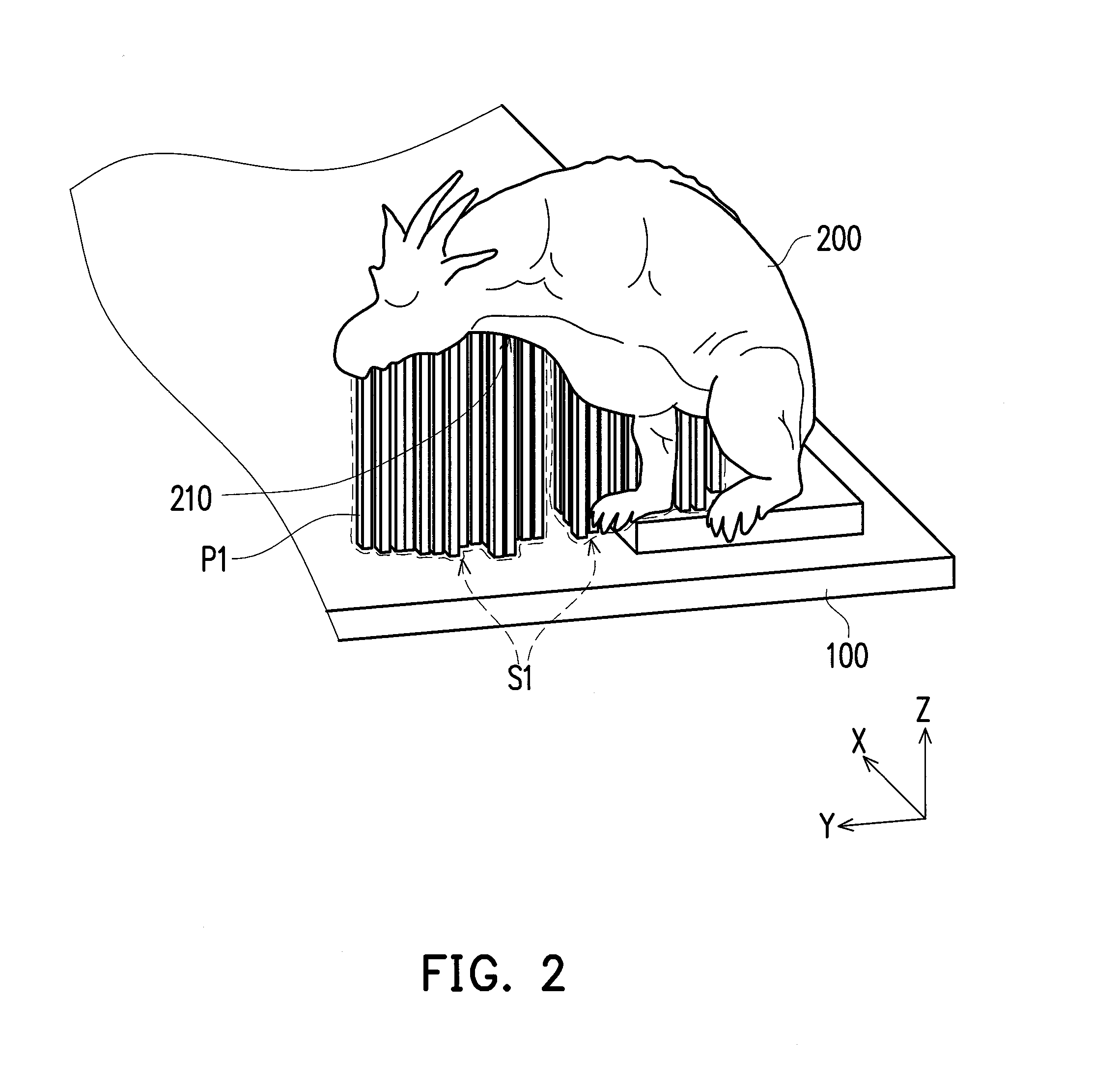

ActiveUS20150137423A1Conserve costShorten production timeAdditive manufacturing apparatusCeramic shaping apparatusEngineering3 dimensional printing

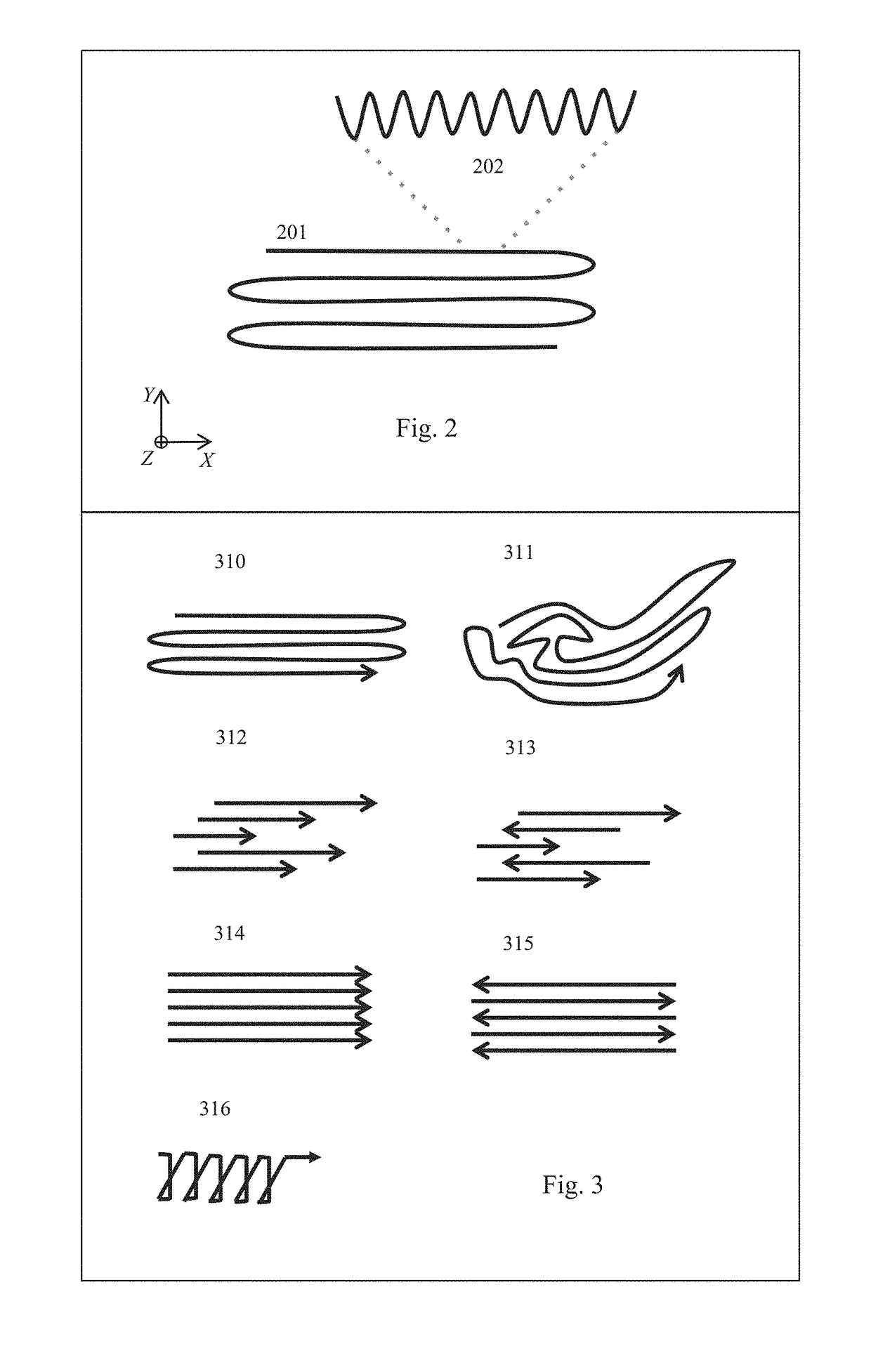

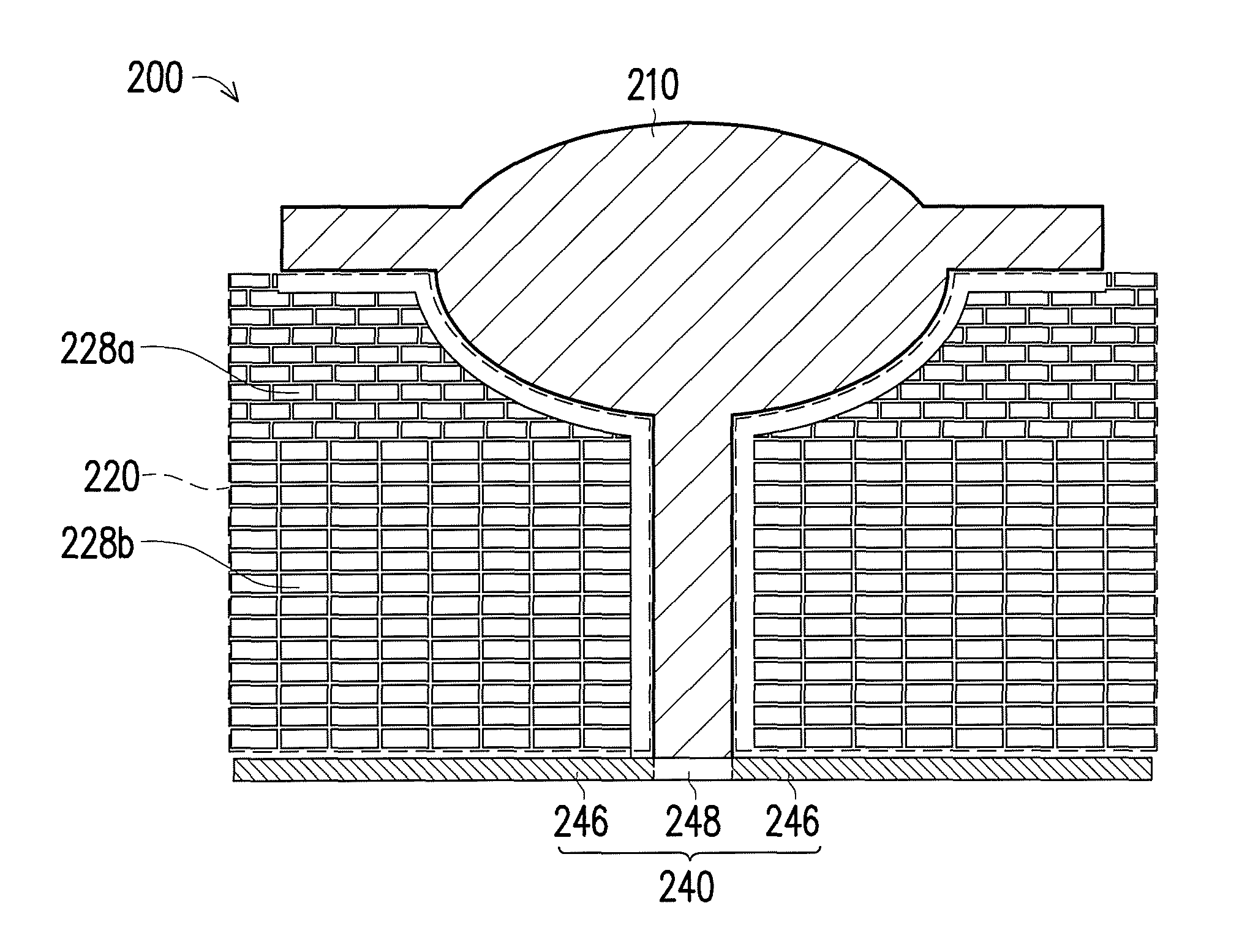

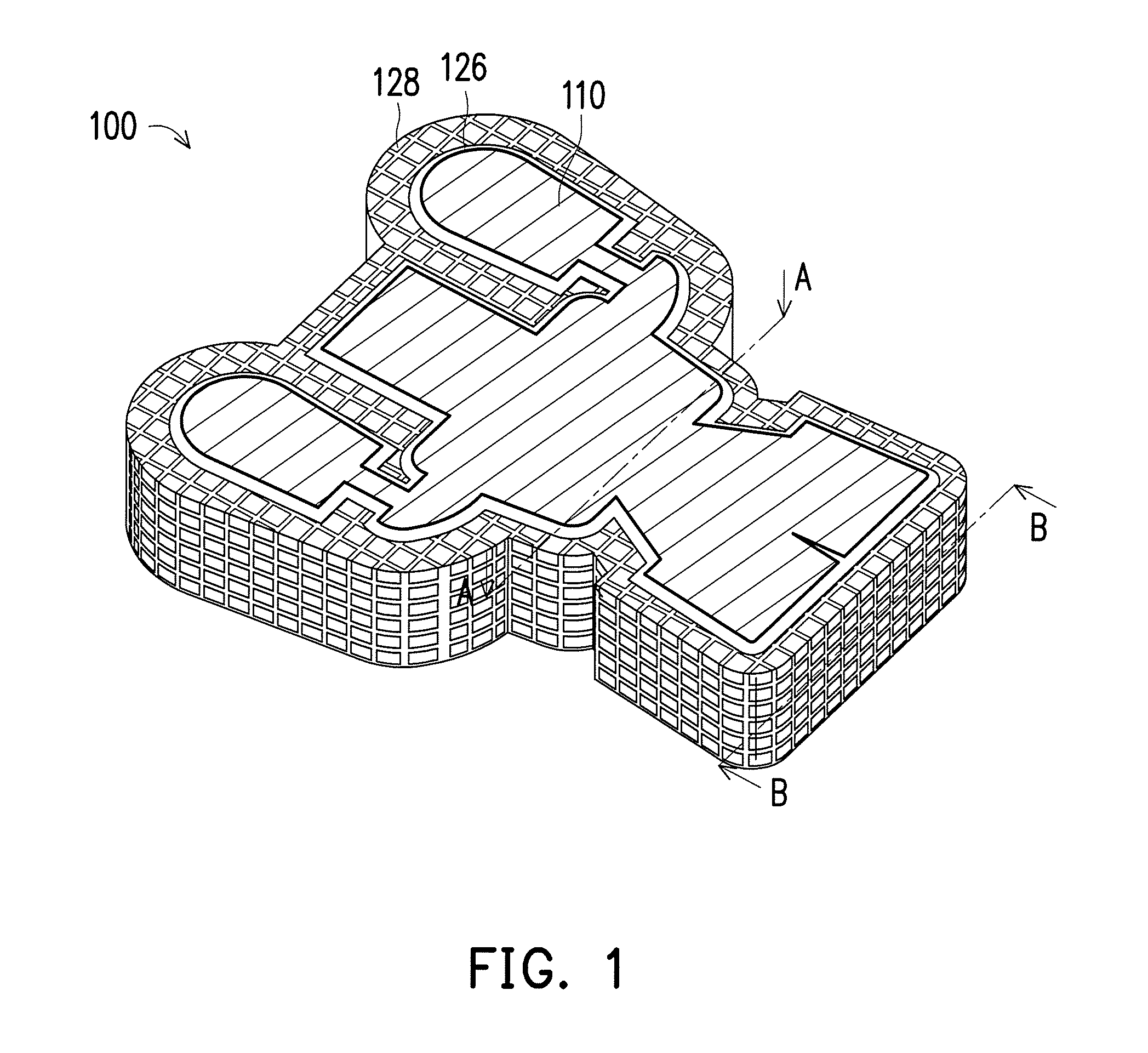

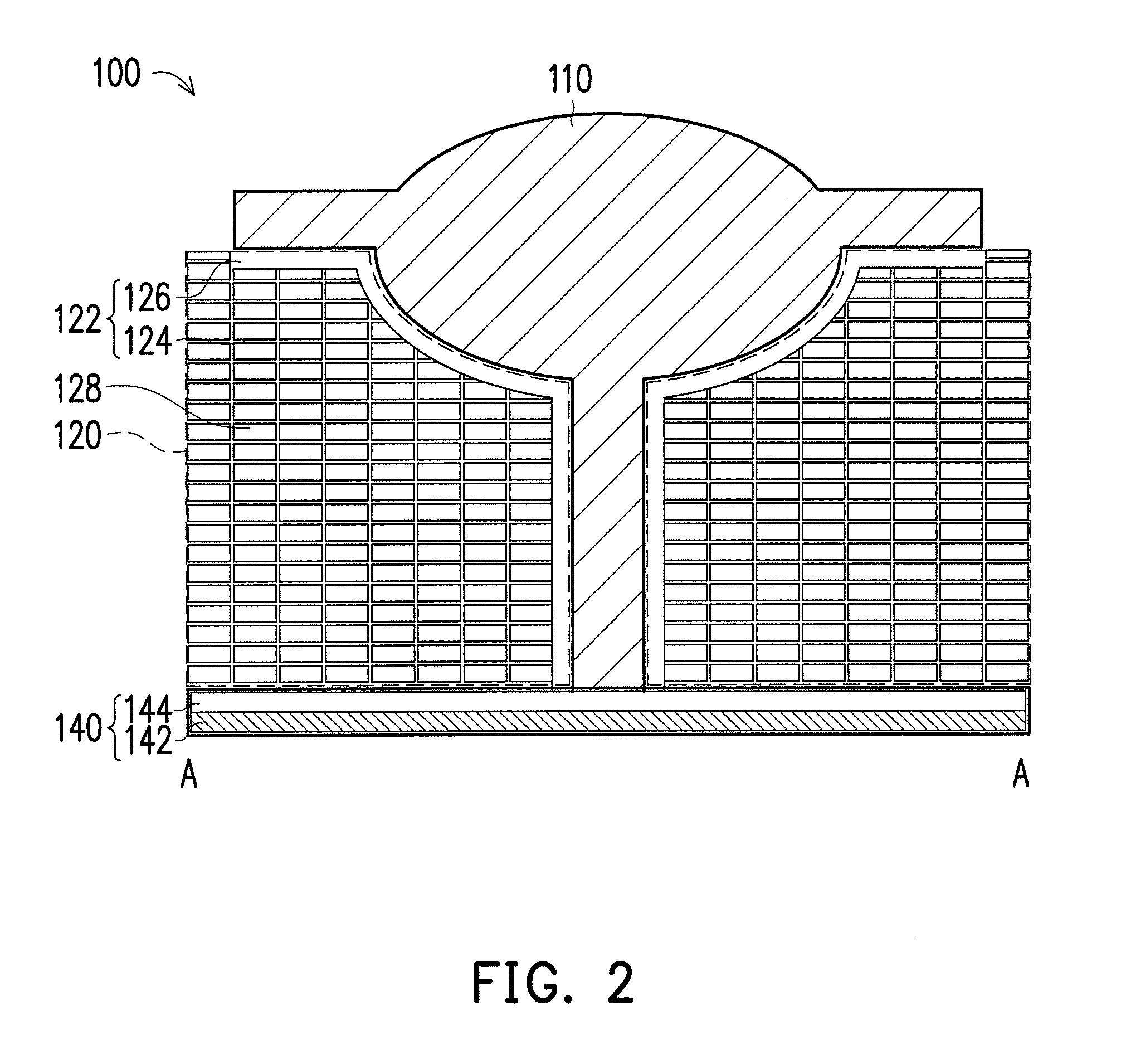

A three-dimensional printing method for forming a three-dimensional object on a base is provided. The method comprises providing a model library comprising at least one supporting member, selecting the at least one supporting member from the model library and disposing the at least one supporting member onto the base. The three-dimensional object is printed over the base and the at the least supporting member, and the three-dimensional object has an overhanging portion relative to the base and the at least one supporting member is filled between the overhanging portion and the base.

Owner:XYZPRINTING +2

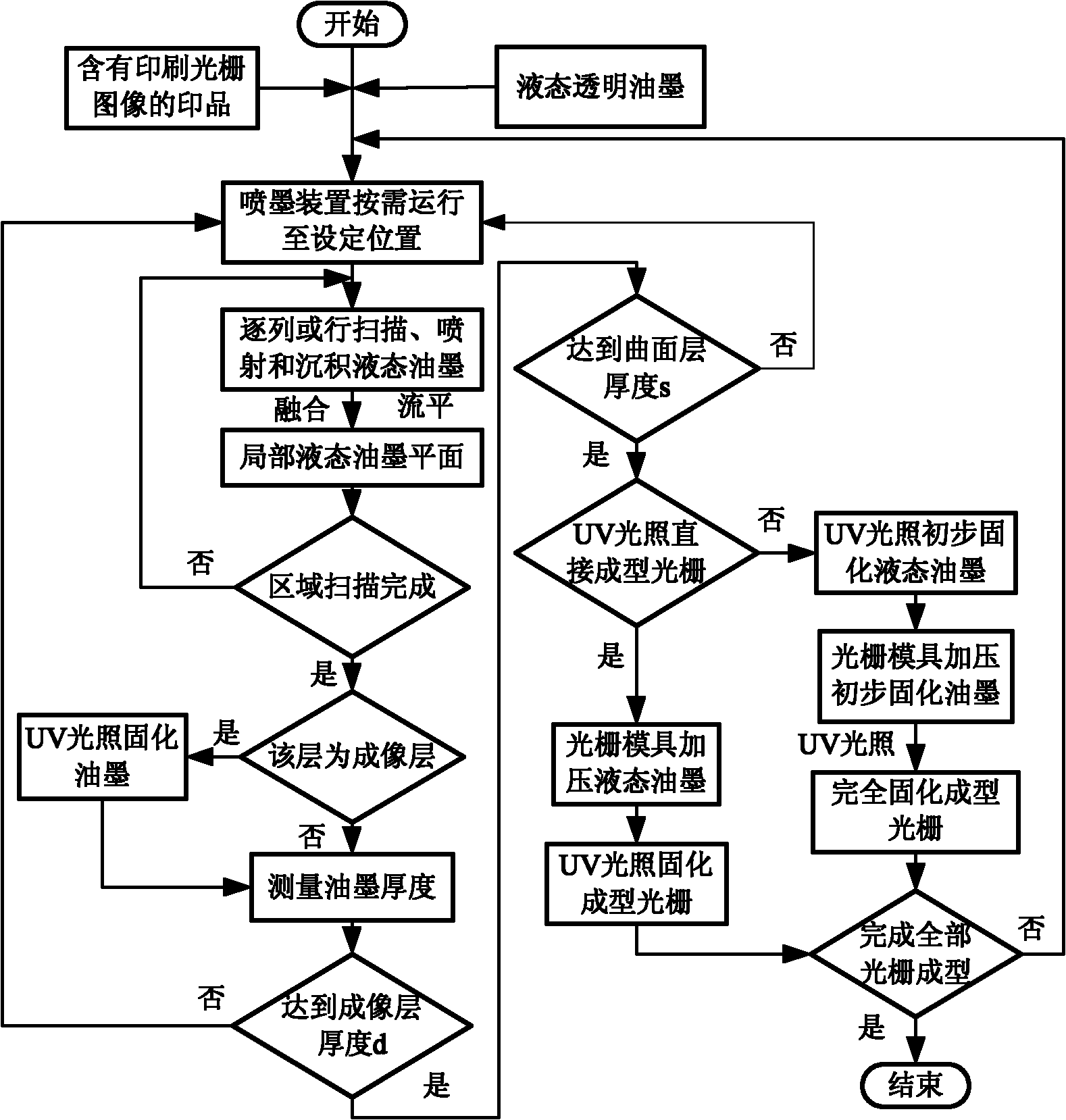

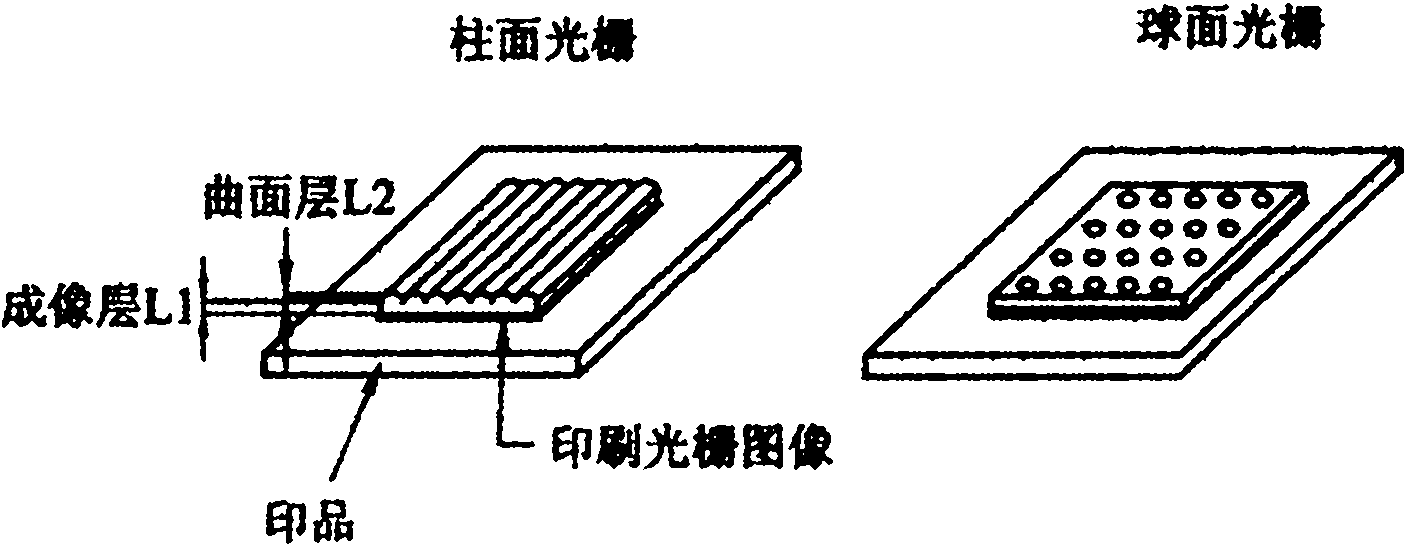

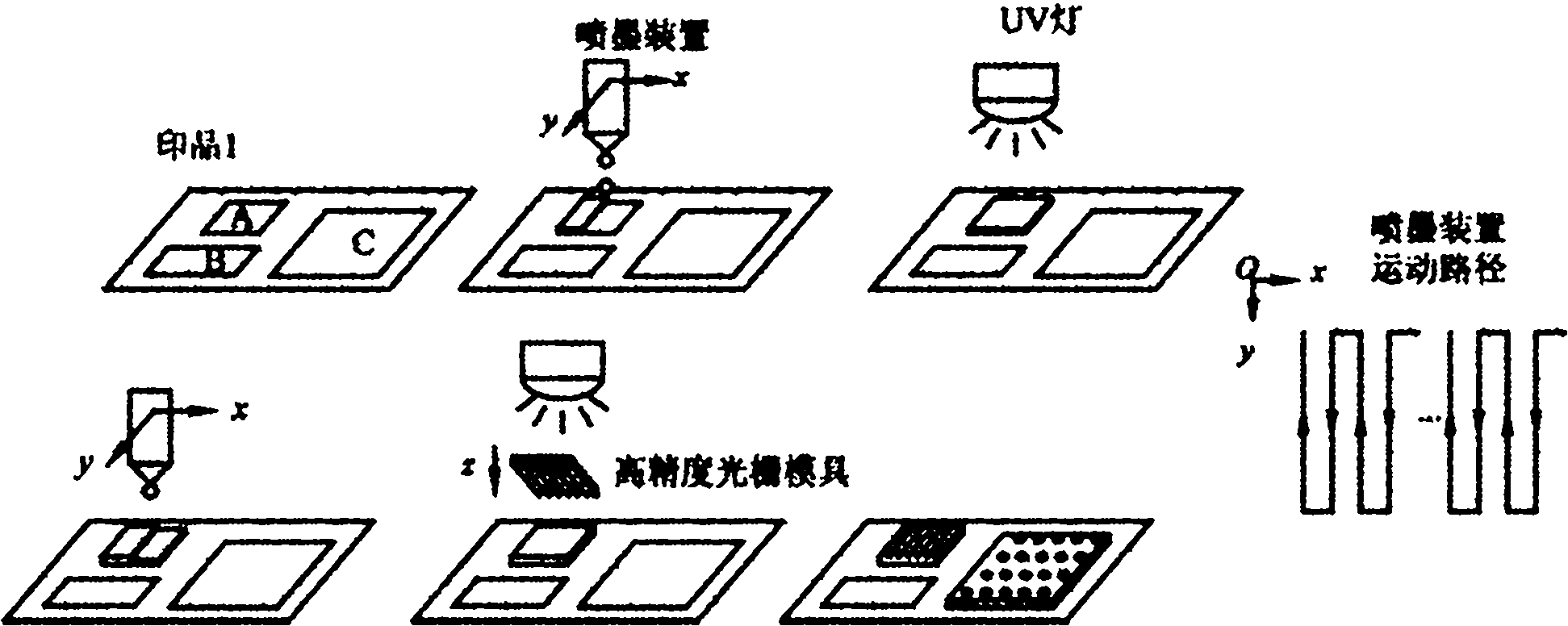

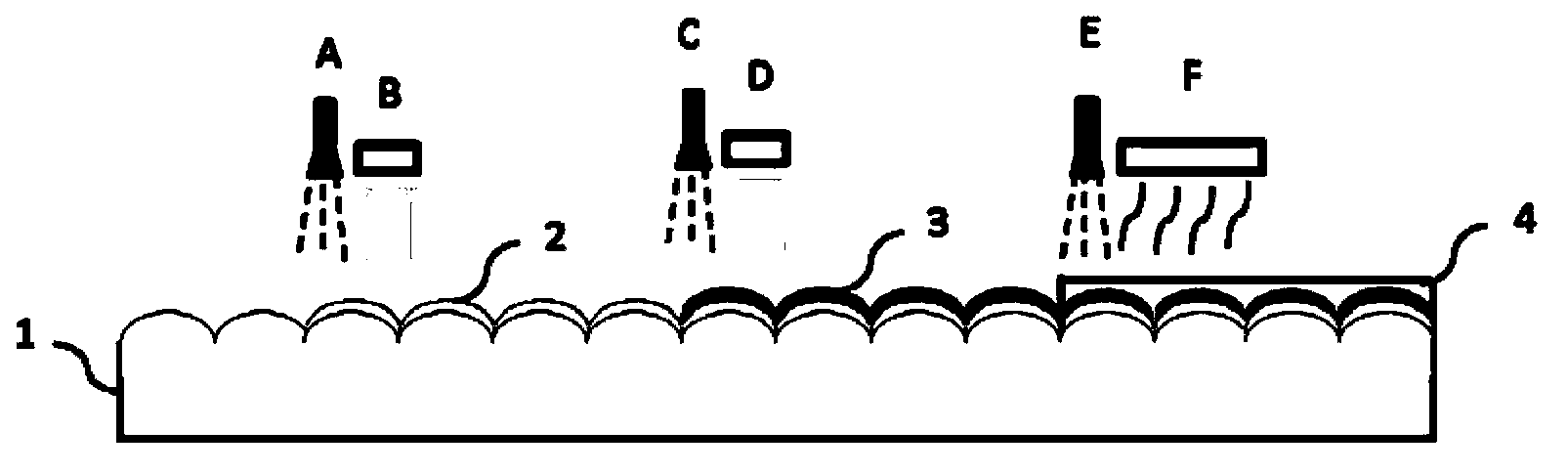

Lenticular printing method for lenticule on demand through ink jet

The invention discloses a lenticular printing method for a lenticule on demand through ink jet, which comprises the following steps of: A, inputting a print containing a printed lenticule image into an inkjet device; B, according to requirements on position and shape of the printed lenticule image, scanning row by row in a printed lenticule image area by using the inkjet device, jetting liquid transparent ink, and depositing the ink into lines so as to form a liquid plane; C, performing ultraviolet (UV) irradiation on the liquid plane to obtain a lenticule imaging layer L1; D, judging whetherthe thickness of the lenticule imaging layer L1 reaches the set threshold value d, if so, executing a step E, otherwise, repeatedly executing the step B and the step C; E, repeating the step B on thecured lenticule imaging layer L1 to obtain a lenticule curve layer L2; F, judging whether the thickness of the lenticule curve layerL2 reaches the set threshold value s, if so, executing a step G, otherwise, repeatedly executing the step E; and G, pressing the curve layer L2 by using a high-precision lenticule mold, and curing through UV irradiation to form the required lenticule.

Owner:中国印刷科学技术研究院有限公司

Three-dimensional printing of three-dimensional objects

ActiveUS20180250746A1Reduce porosityHigh aspect ratioProgramme controlAdditive manufacturing apparatus3 dimensional printingBiomedical engineering

Owner:VELO3D INC

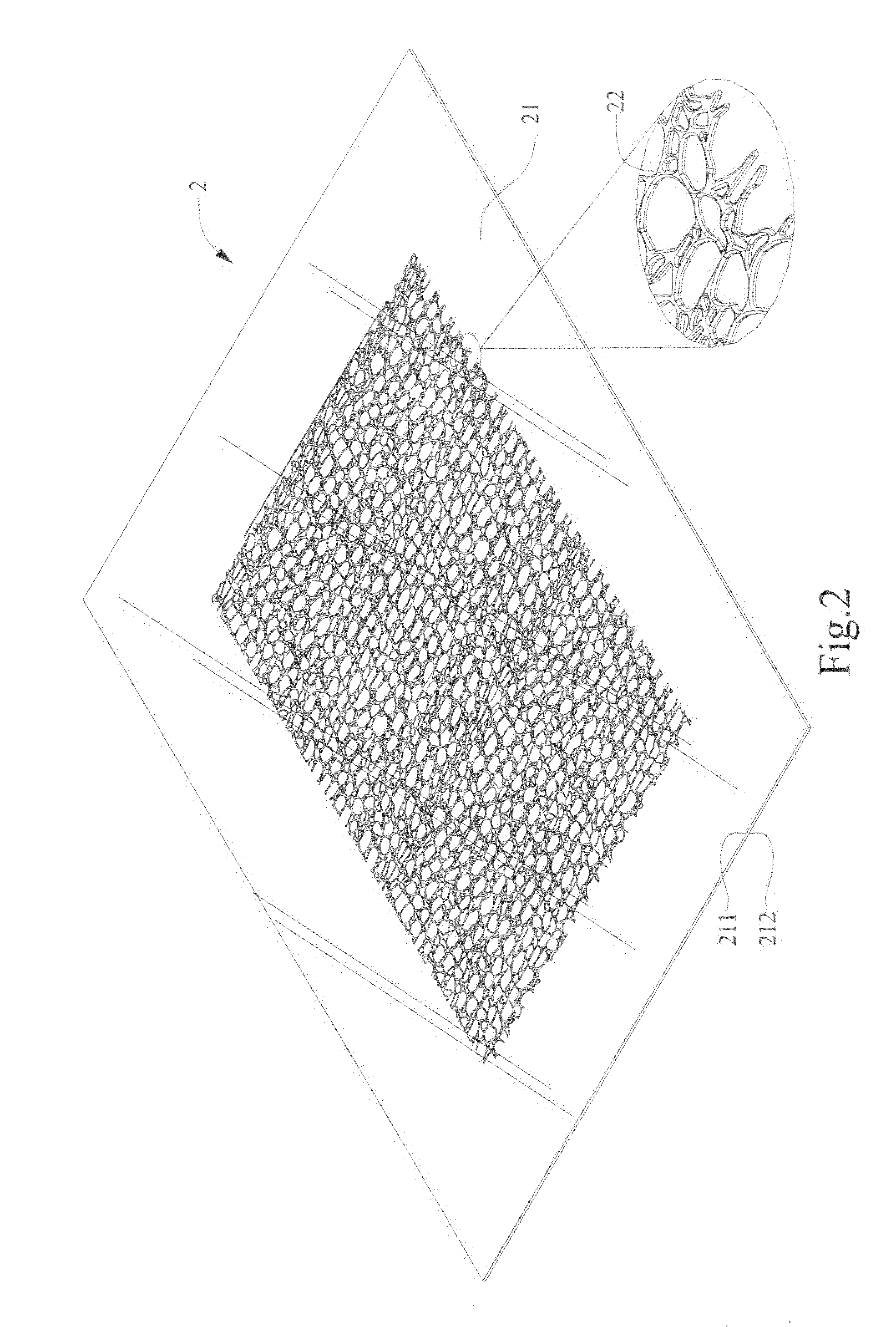

Three-dimensional printing structure

ActiveUS9399323B1Improve support strengthHigh strengthAdditive manufacturing apparatus3D object support structuresBrickEngineering

Owner:XYZPRINTING +2

Three-dimensional printing

A process for forming a three-dimensional article in sequential layers in accordance with a digital model of the article. The process comprises the steps of defining a layer of a first liquid, applying a second liquid to the first liquid layer in a pattern corresponding to the digital model, and repeating these steps to form successive layers. The first liquid comprises a first active component and the second liquid includes a second active component capable of reacting with the first reactive component so that the article is built up in layers.

Owner:3D SYST INC

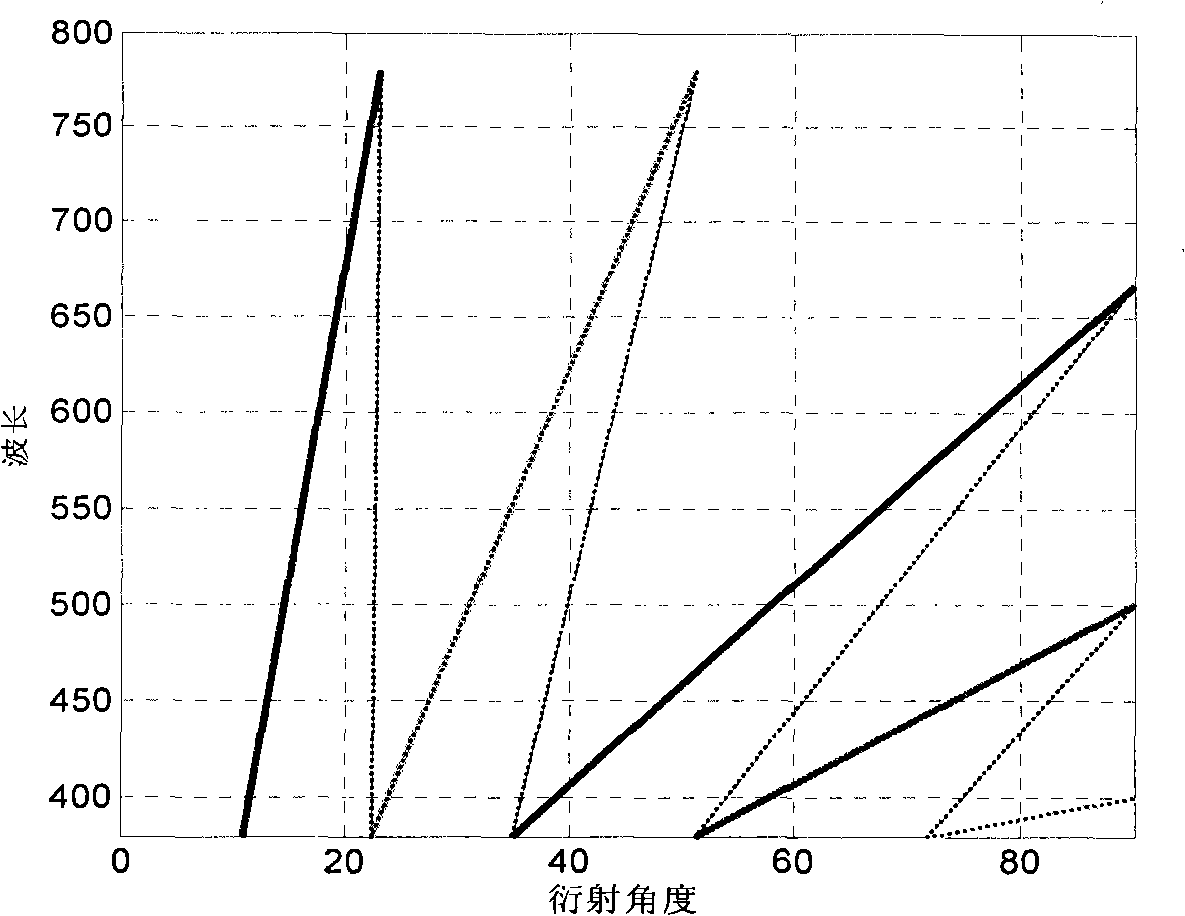

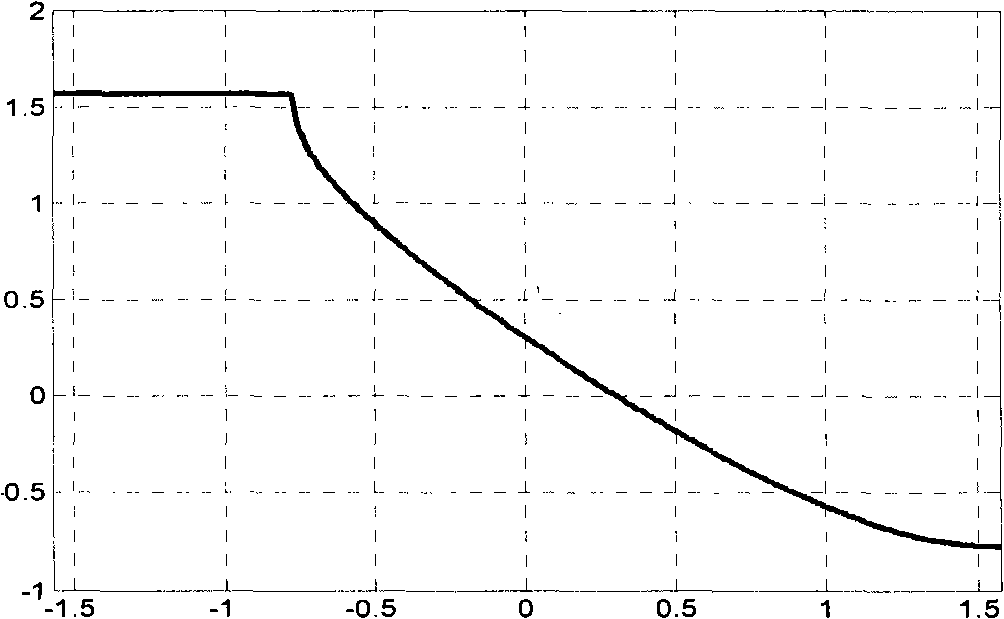

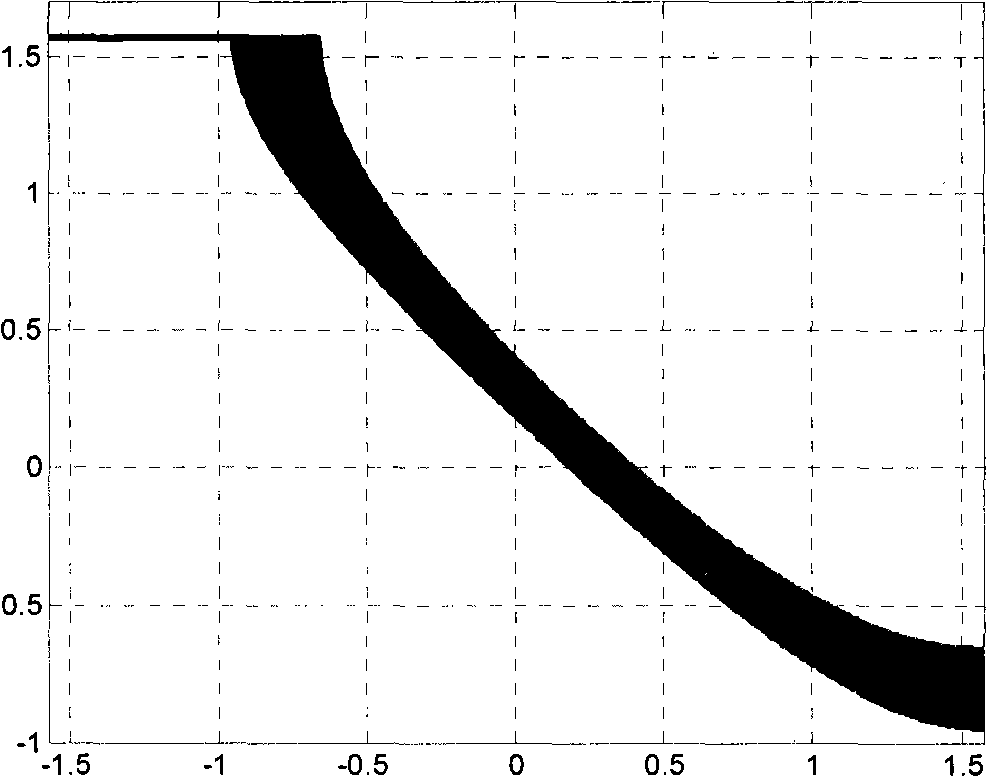

Grating-based rainbow hologram chromaticity detection and evaluation method

InactiveCN101915617AAccurate responsivenessExact sample differenceRadiation pyrometryColor measuring using electric radiation detectorsRainbow hologramTest sample

The invention provides a grating-based rainbow hologram chromaticity detection and evaluation method, which mainly comprises the following steps of: determining the type and optical parameters of a diffraction grating, and selecting an optical filter according to the type characteristics of the grating; preserving or shielding specular reflection light according to actual needs by adopting a diffused light source; and testing the reflectance spectrums of a sample, calculating spectral errors and metamerism indexes of a reference and the sample according to the reflectance spectrums of the tested sample, and evaluating the chromaticity information of a grating-based rainbow hologram image according to the spectral errors and the metamerism indexes. The method has the advantages of objectively reflecting the chromaticity information between the sample and the reference and accurately reflecting chromaticity errors between the sample and the reference, along with simplicity and high speed, and is popularized and utilized to effectively control the chromaticity quality of the grating-based rainbow hologram image and promote laser holographic anti-counterfeiting, three-dimensional printing and control over the quality of grating-based high-end products.

Owner:永发印务(东莞)有限公司

Three-dimensional printing equipment, printing method and packaging box

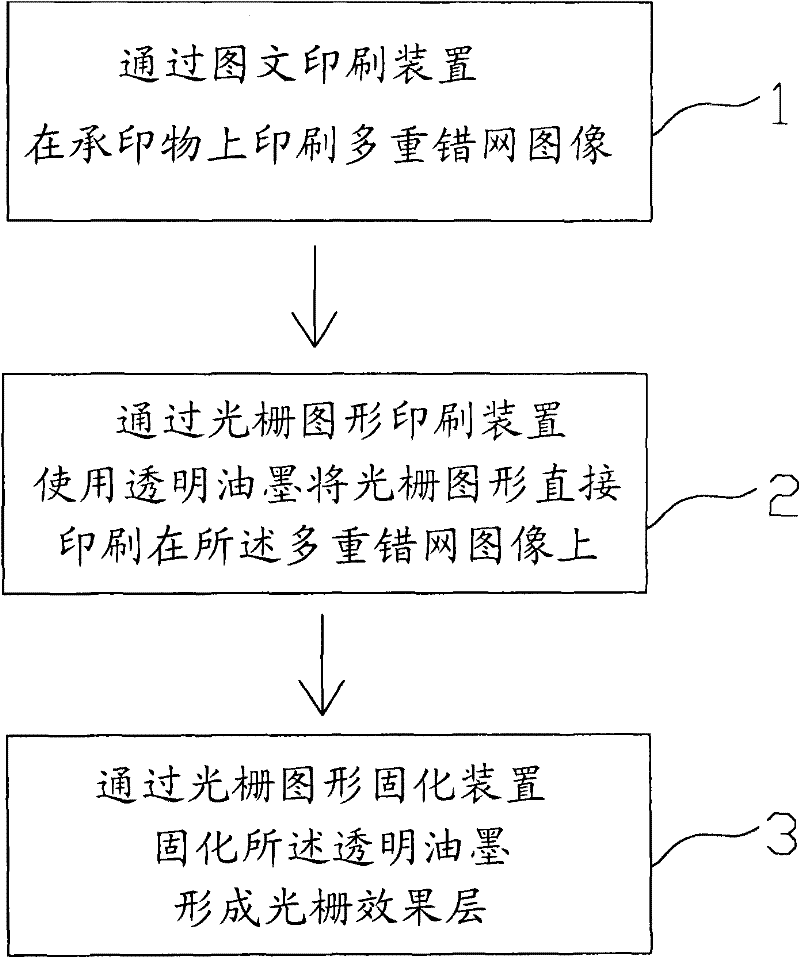

InactiveCN102673097ANo wasteSave materialRotary intaglio printing pressPattern printingGraphicsGrating

The invention provides three-dimensional printing equipment which comprises an image-text printing device and a raster graphic printing device, wherein the image-text printing device is used for printing a multigrid image onto a printing material; and the raster graphic printing device is positioned at the down stream of the image-text printing device, and transparent ink is used to directly print raster graphics onto the multigrid image of the printing material. The invention further provides a three-dimensional printing method which comprises the following steps that the multigrid image is printed onto the printing material through the image-text printing device; and the transparent ink is used to directly print the raster graphics onto the multigrid image through the raster graphic printing device. The invention also provides a packaging box with a three-dimensional image, and the three-dimensional image is printed through the three-dimensional printing method. Accordingly, the invention not only can save materials, but also is environmental-friendly, has high production efficiency and a wide application scope.

Owner:SHENZHEN JINJIA GRP

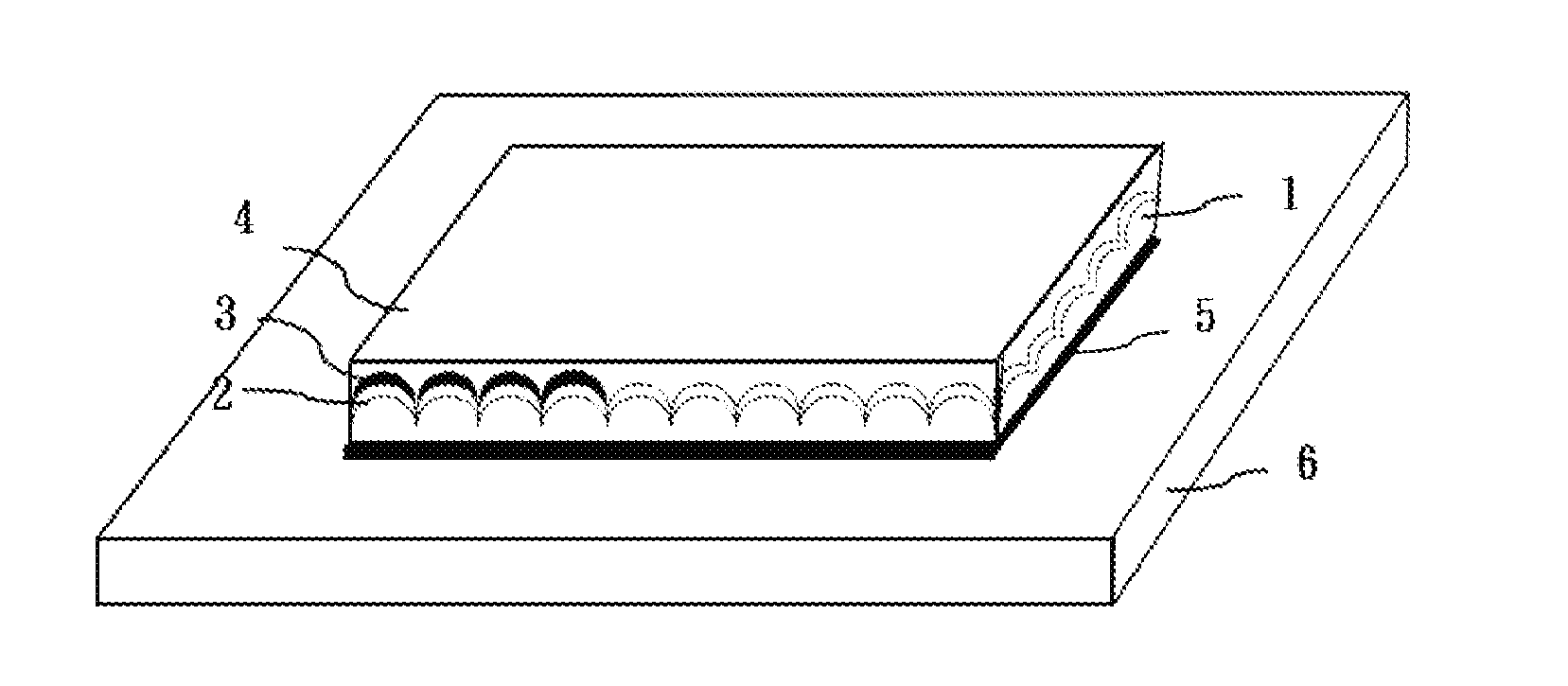

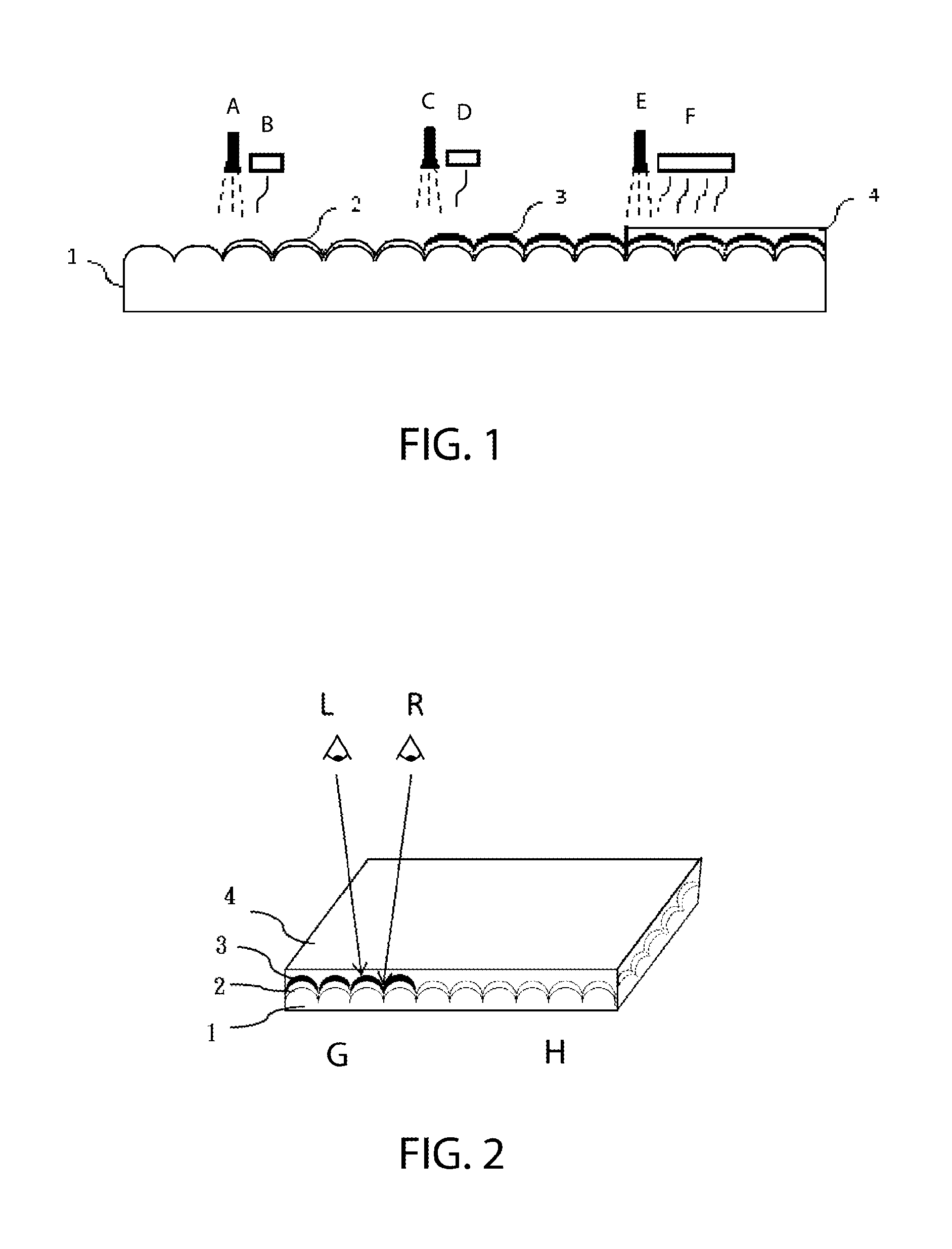

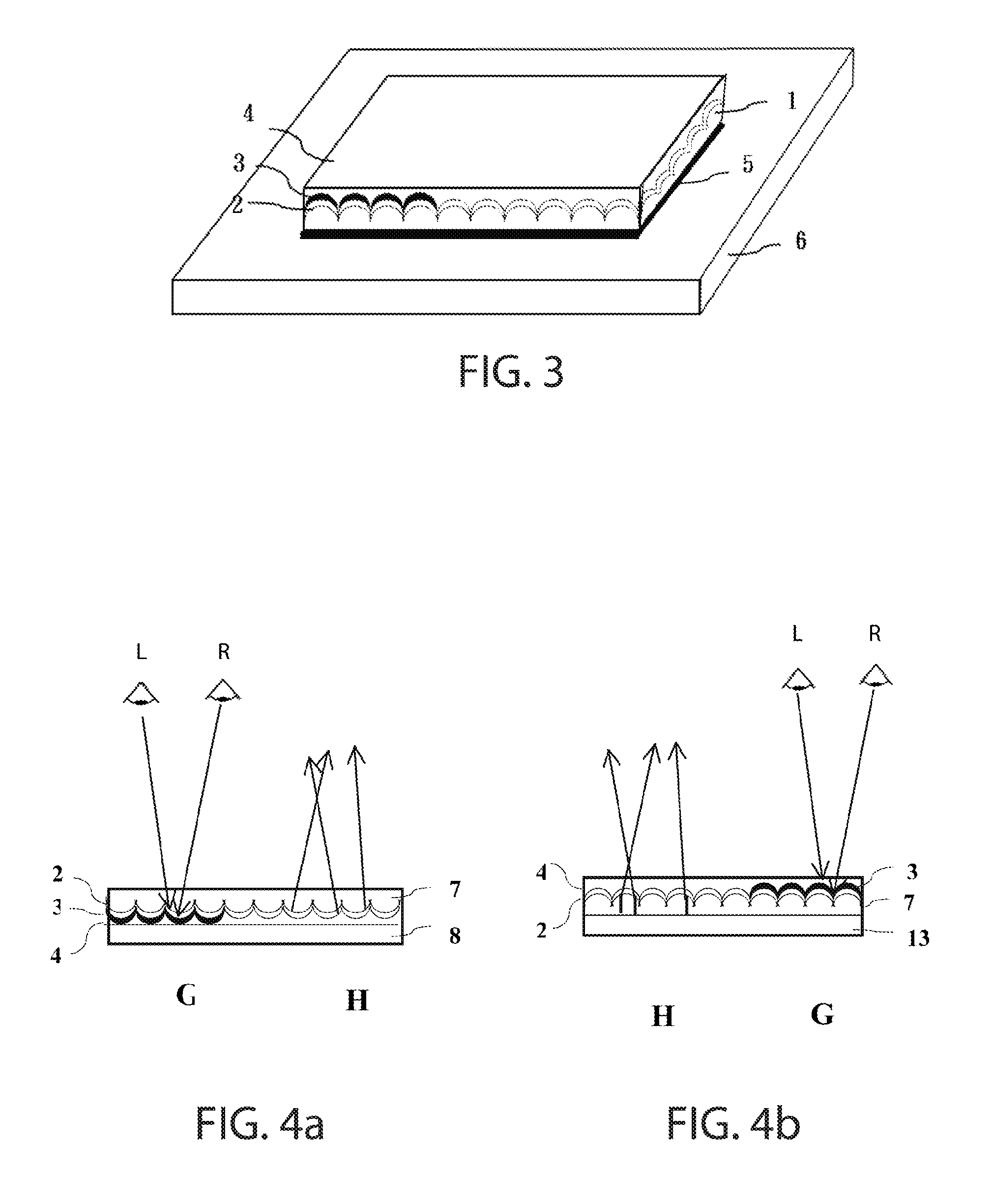

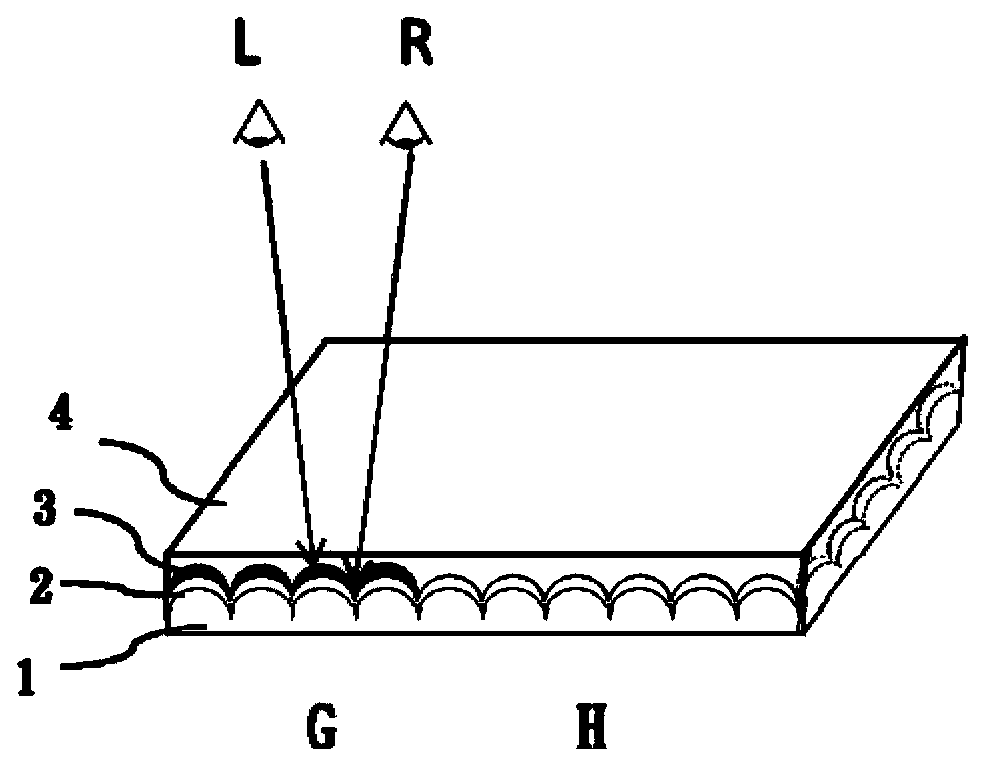

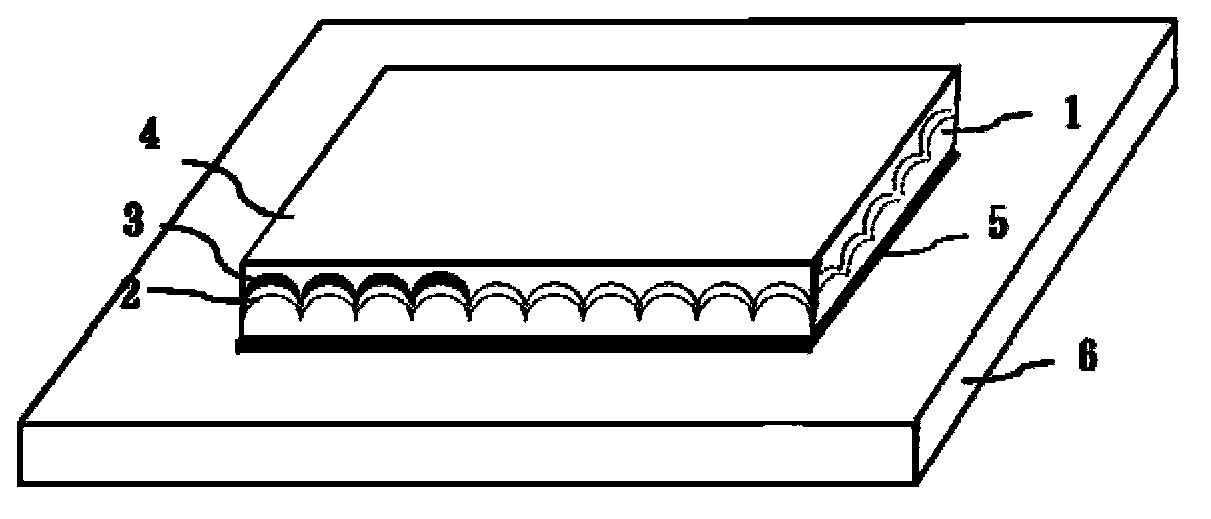

Method of stereoscopic printing and the decorative plate and light box made thereof

InactiveUS20140043679A1Additive manufacturing apparatusRadiation applicationsMicro structureImage resolution

This invention describes a method of stereoscopic printing and its application in decorative plate and light box. The stereoscopic printing method includes a substrate with concave and convex surface micro structures followed by printing with electron beam or UV light curable ink to retain the surface morphology after printing. The printing resolution is between 5 and 20 times the density of concave and convex surface structure to create the decorative plate with visual depth perception. If the micro structured substrate is transparent, a high contrast image on a decorative plate or a light box can be obtained by integration of a reflective film or a back light unit.

Owner:HWANG YU CHEN

Powder particle layerwise three-dimensional printing process

ActiveUS10040216B2Improve structural strengthReduce the temperatureAdditive manufacturing apparatusTransportation and packagingMetal alloyNanoparticle

Three-dimensional printing processes are disclosed which utilize printable fluids comprising a carrier fluid, a polymeric binder, and nanoparticles. The three-dimensional printing processes are useful for making articles from a build material powder, e.g., a ceramic, metal, metal alloy, or intermetallic powder. The nanoparticles enable low temperature interparticle bonding of the build material powder particles, e.g., by forming bridging bonds between adjacent powder particles, and / or increasing the interparticle friction between the build material powder particles to enhance the structural strength of the as-built article during a thermal treatment over at least a part of the temperature range which has as its low end the temperature at which the structural strength due to the binder becomes insubstantial and as its high end the temperature at which the structural strength due to interparticle sintering of the build material powder becomes substantial, i.e., the article's debile temperature range. Green density improvements are achievable.

Owner:THE EX ONE +1

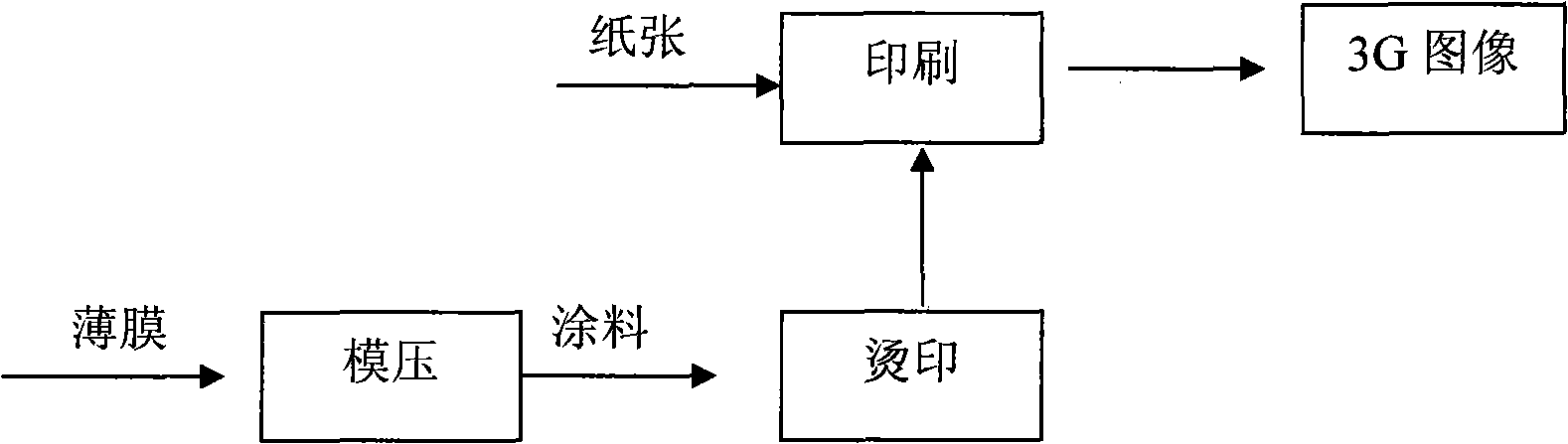

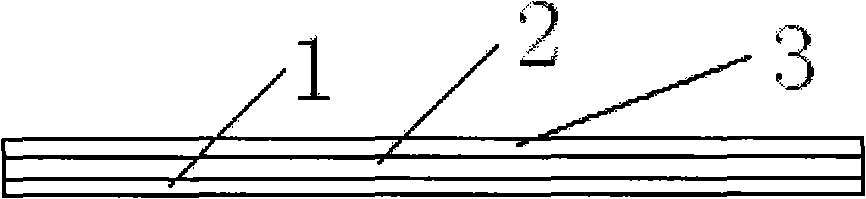

Stock having green environment-protective three-dimensional stereo grating effect image and transfer making method

InactiveCN101301830AReduce material consumptionReduce product costOther printing matterPattern printingMaterial consumptionEnvironmental resistance

The invention relates to a printing stock with green environment protective 3D solid grating effect image and a transfer manufacture method thereof. The invention belongs to the technical field of 3D solid printing of packaging and upholstering. The stock includes a printing substrate with a plane printing image; a compound medium layer is arranged on the printing substrate; a grating effect layer obtained by carrying out laser grating effect mould pressing treatment and peeling transfer on a film is arranged on the compound medium layer. The transfer manufacture method includes the following steps: 1, carrying out plane colorful printing on the stock; 2, providing a film the surface of which is coated with an isolating layer; 3, carrying out laser grating effect mould pressing treatment on the film to generate the grating effect layer; 4, transferring the grating effect layer to the printing surface of the printing stock. The invention transfers the grating effect layer to the printing surface of paper which is provided with the plane printing image, thus leading the printing surface of paper to take a special vision feeling of solid vision and heteroclitic cartoon. The invention reduces the material consumption and the product cost, adapts to the requirements of the product to resist fake and improve the grade, is green and environmentally protective and can not cause pollution to the environment.

Owner:YANTAI BOYUAN TECH MATERIALS

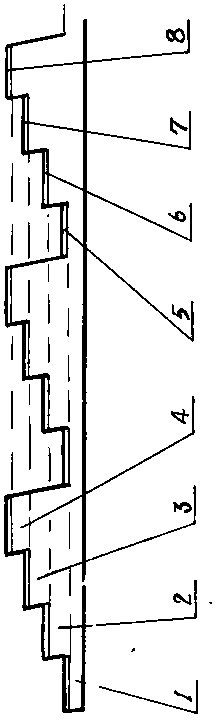

Three-dimensional print film structure

InactiveUS20110117326A1Synthetic resin layered productsThin material handlingPlastic materialsAdhesive

A three-dimensional print film structure is applicable to in-mold injection-molded decoration. The three-dimensional print film structure comprises a film, a three-dimensional printing layer, a releasing layer, a pattern layer, an impact-resistant layer and a thermal tolerance bonding adhesive. The film has a first surface and a second surface. The three-dimensional printing layer is disposed on the first surface. The releasing layer is disposed on the second surface. The pattern layer is disposed on one side of the releasing layer. The impact-resistant layer is disposed on one side of the pattern layer. The thermal tolerance bonding adhesive is disposed on one side of the impact-resistant layer. When a mold is closed, the three-dimensional printing layer can form a three-dimensional patterned decoration on a plastic material so as to provide an aesthetic effect.

Owner:CHIU SOU KUEIN +1

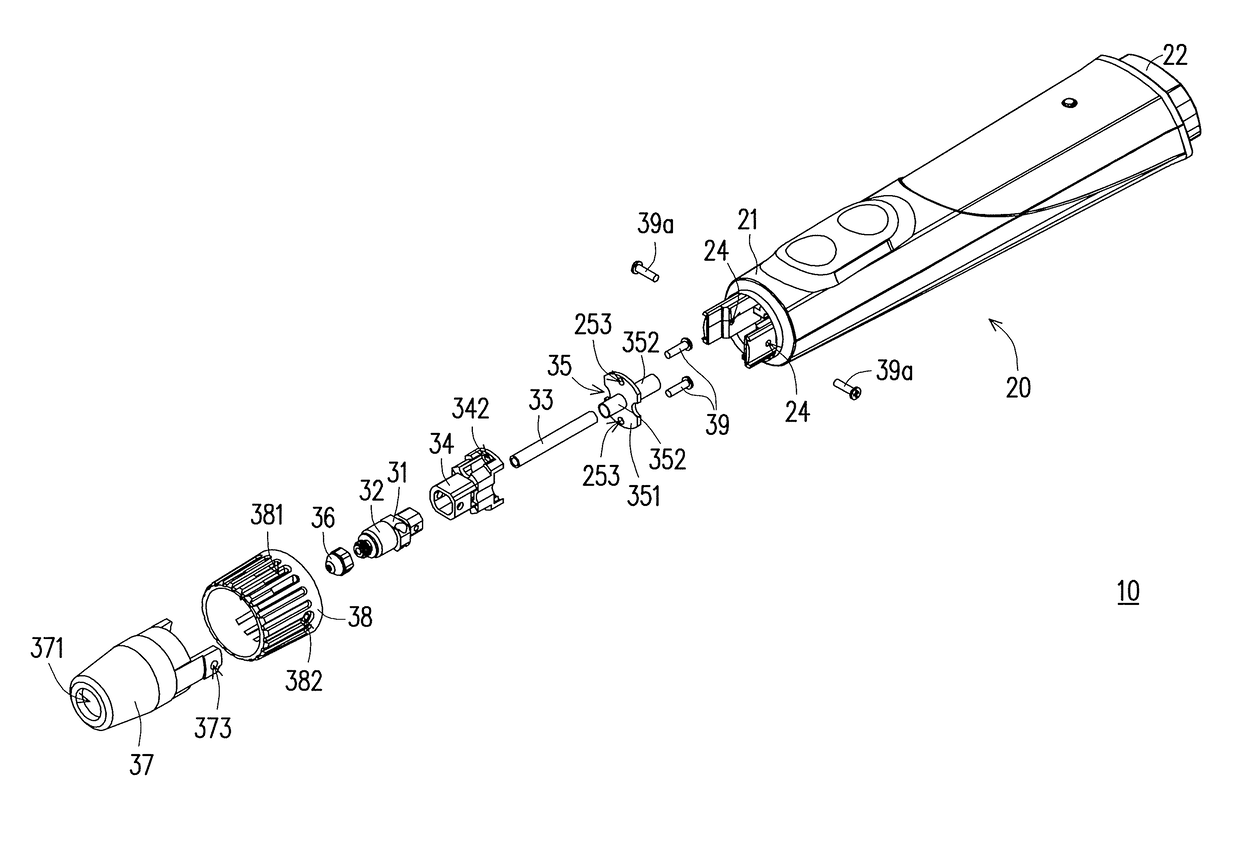

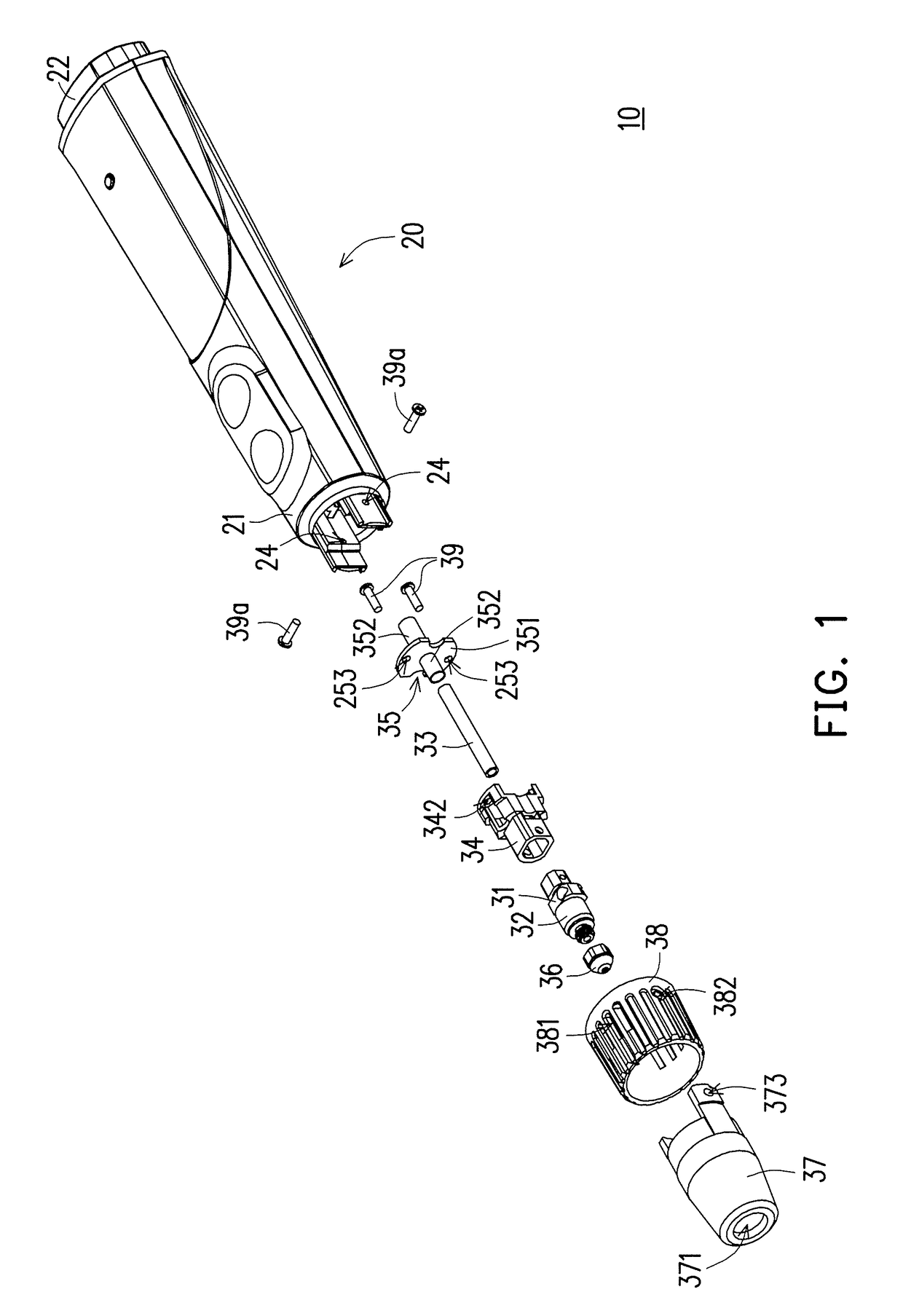

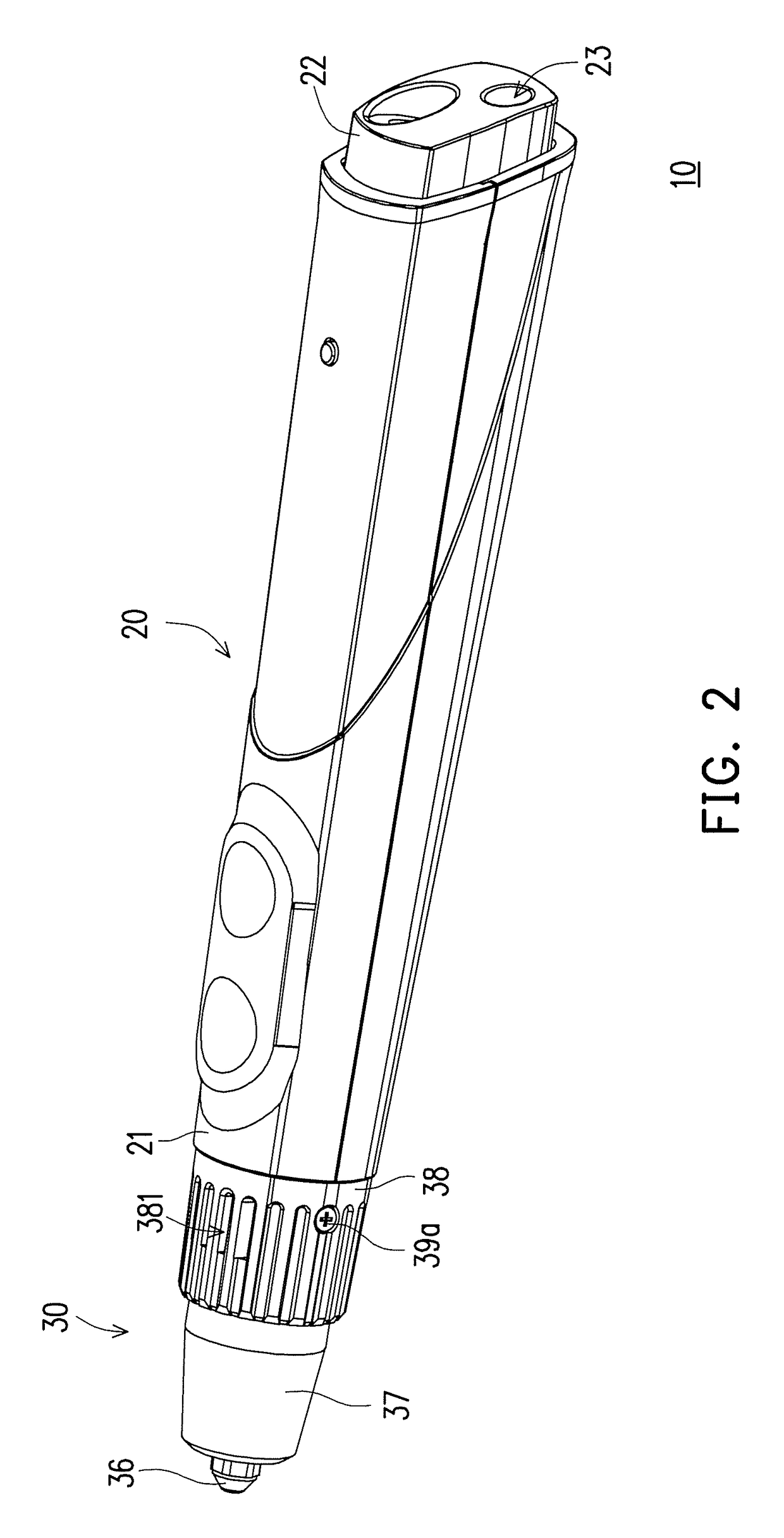

Heating head for three-dimensional printing pen

ActiveUS20170190105A1Improve insulation effectMaintain temperatureManufacturing heating elementsHeating element shapesEngineeringHeat pipe

The invention provides a heating head for a three-dimensional printing pen. The heating head includes a heating pipe, a heating member, a heat insulation pipe, a heat insulation sleeve, and a heat sink. The heating member is disposed on the heating pipe. The heat insulation pipe penetrates into the heating pipe. The heat insulation sleeve is sleeved on the heating pipe and opposite to the heating member. The heat insulation sleeve partly covers the heat insulation pipe, and the heat insulation pipe and the heat insulation sleeve are separated by the heating pipe. The heat sink and the heat insulation sleeve mutually lean against, wherein the heat insulation sleeve is located between the heating member and the heat sink, and the heat insulation pipe penetrates into the heat sink.

Owner:XYZPRINTING +1

Three-dimensional printing system

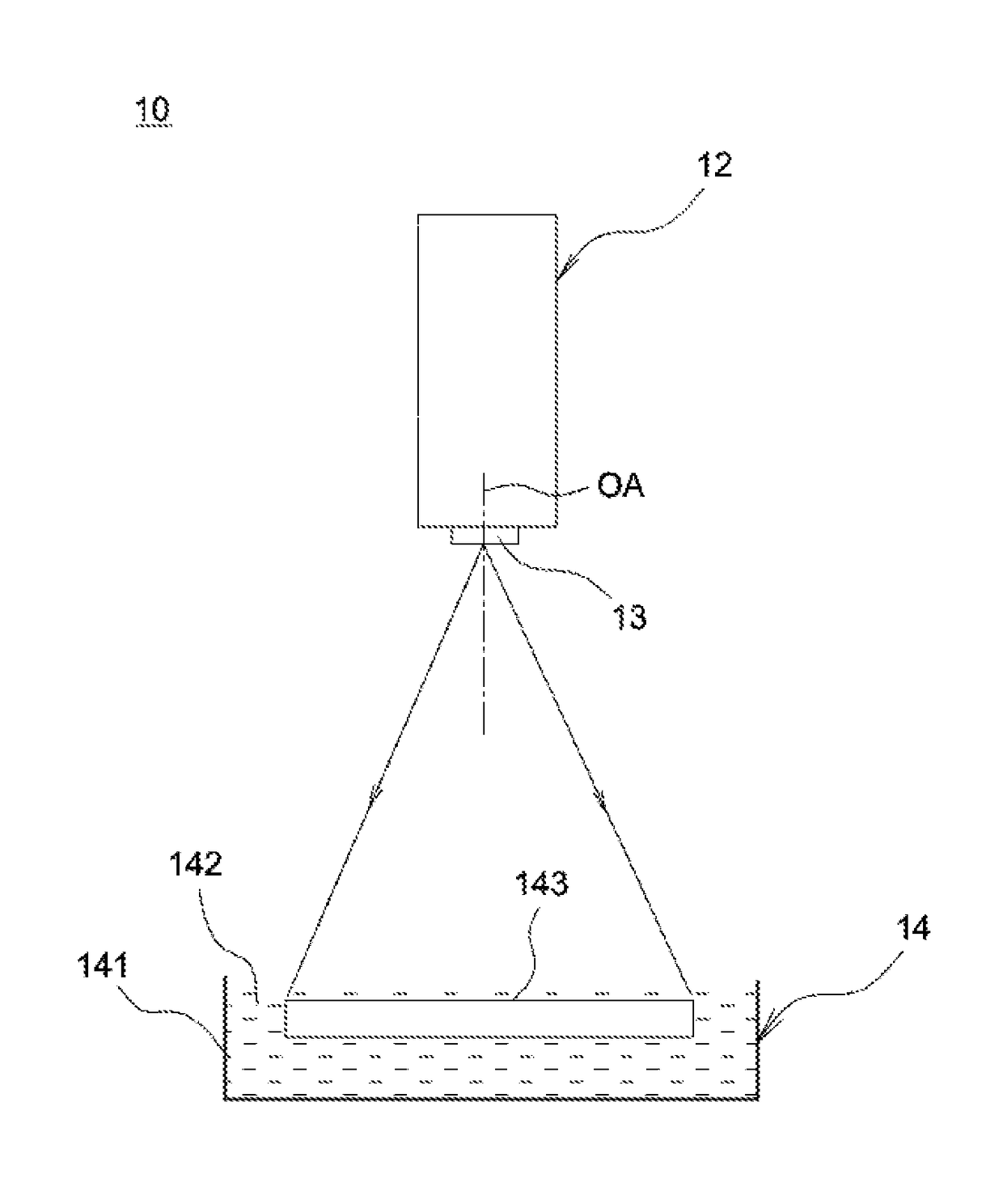

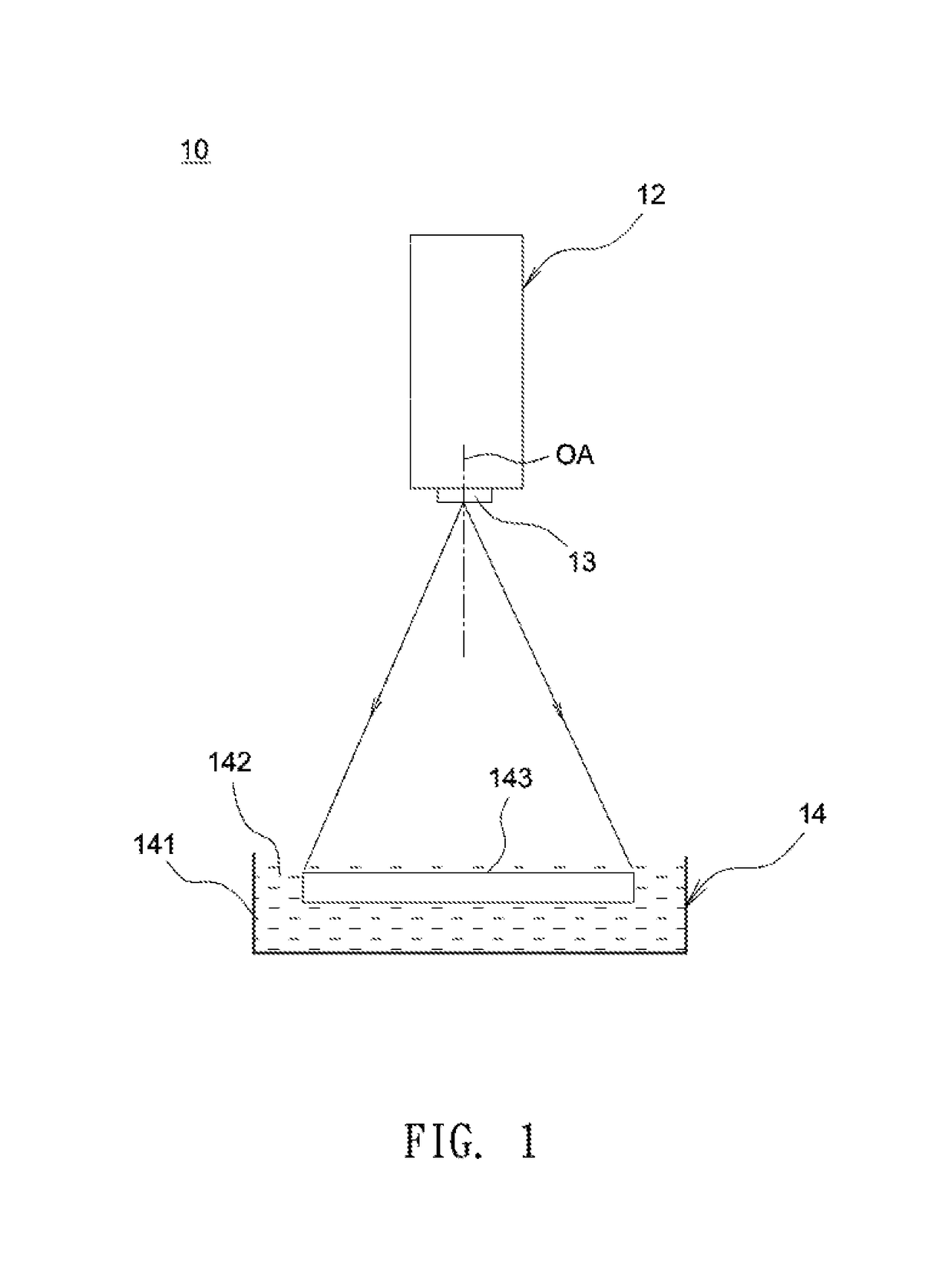

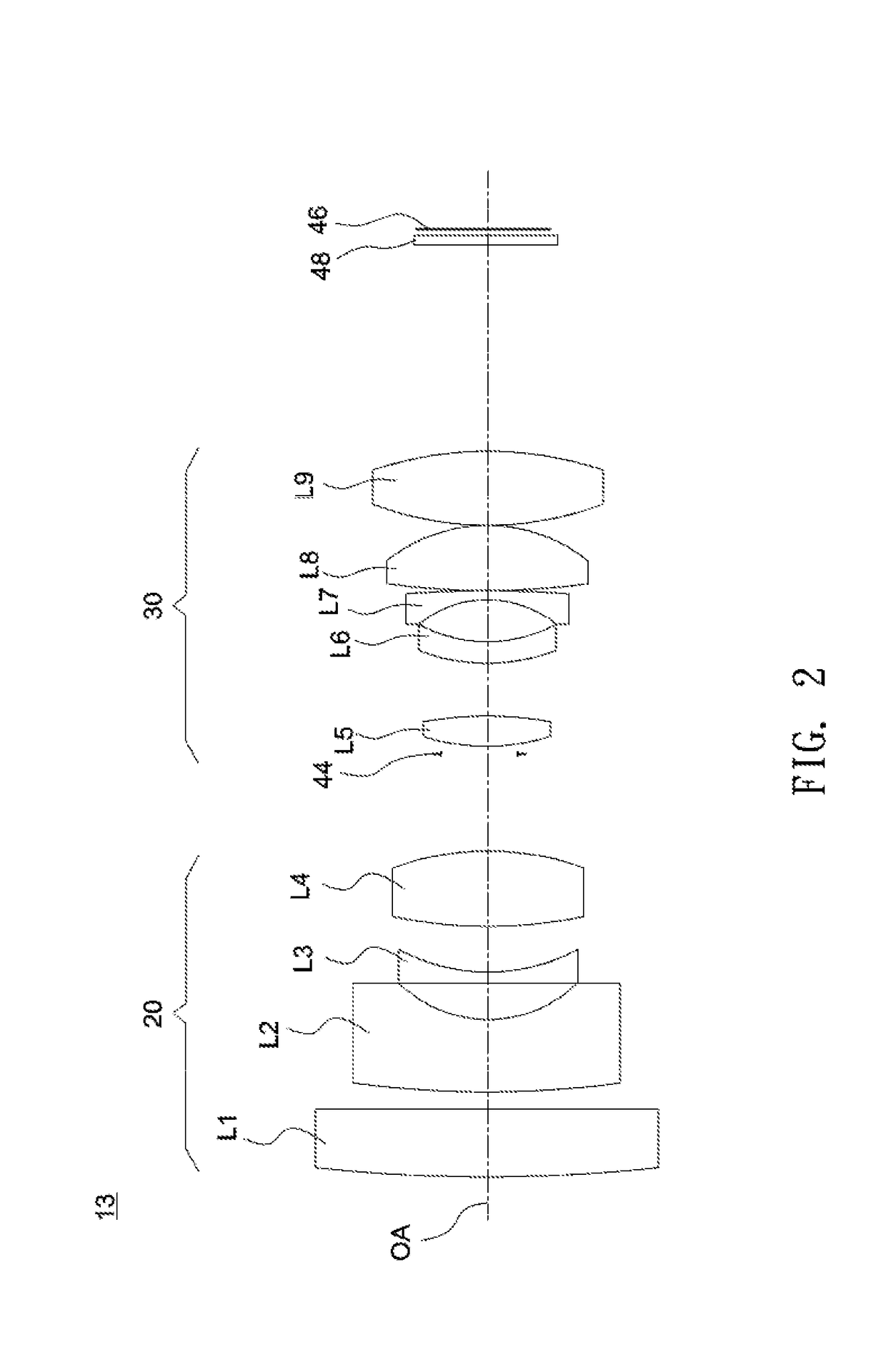

ActiveUS20180056605A1Additive manufacturing apparatus3D object support structuresLight beamEngineering

A three-dimensional printing system includes a build device and an optical projection engine. The build device includes a curing tank, a photocurable material and a build platform, and the photocurable material and the build platform is disposed in the curing tank. The optical projection engine has a zoom lens for projecting image beams with at least a first pixel size and a second pixel size on the build platform to cure the photocurable material, and the first pixel size is different to the second pixel size.

Owner:YOUNG OPTICS

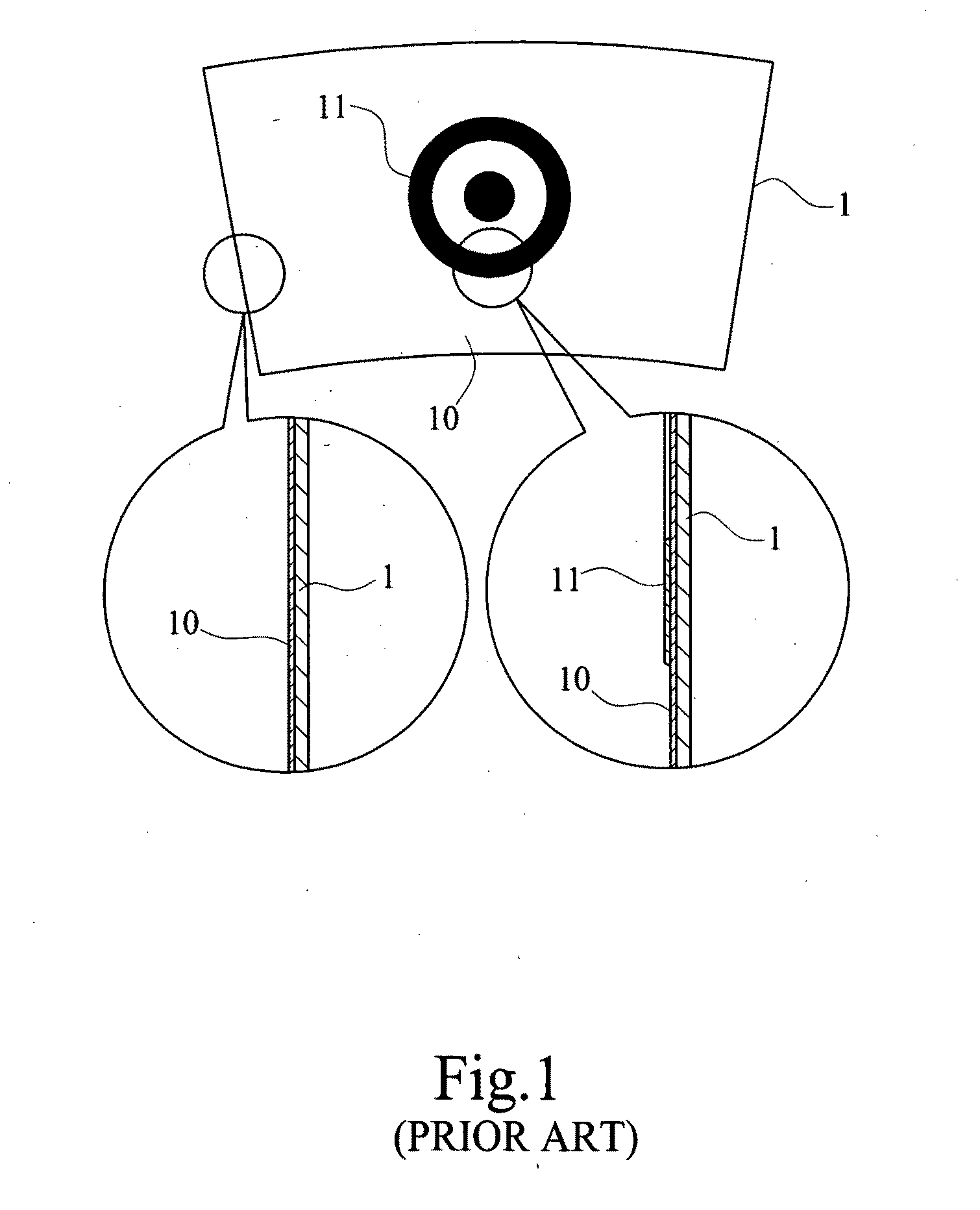

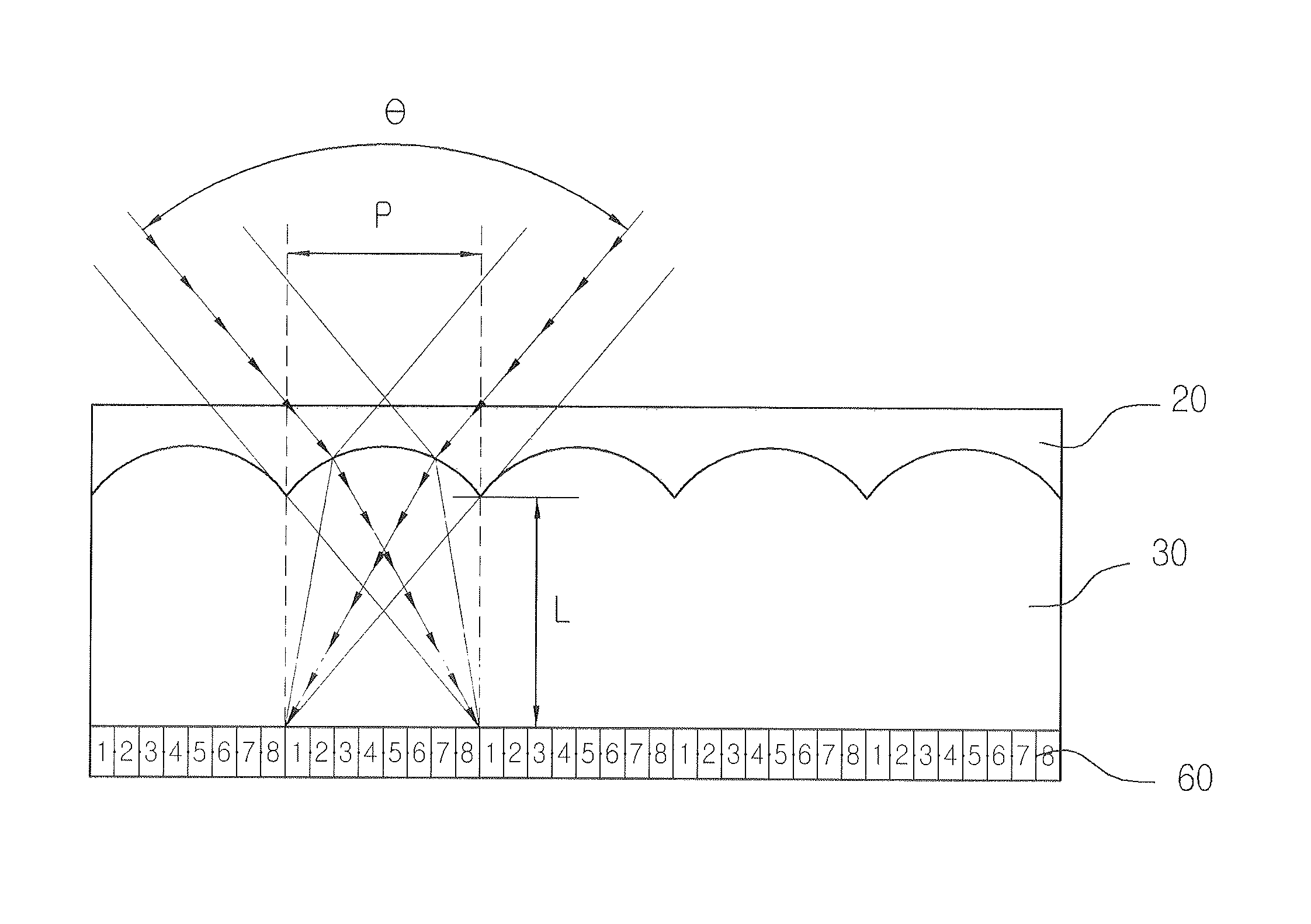

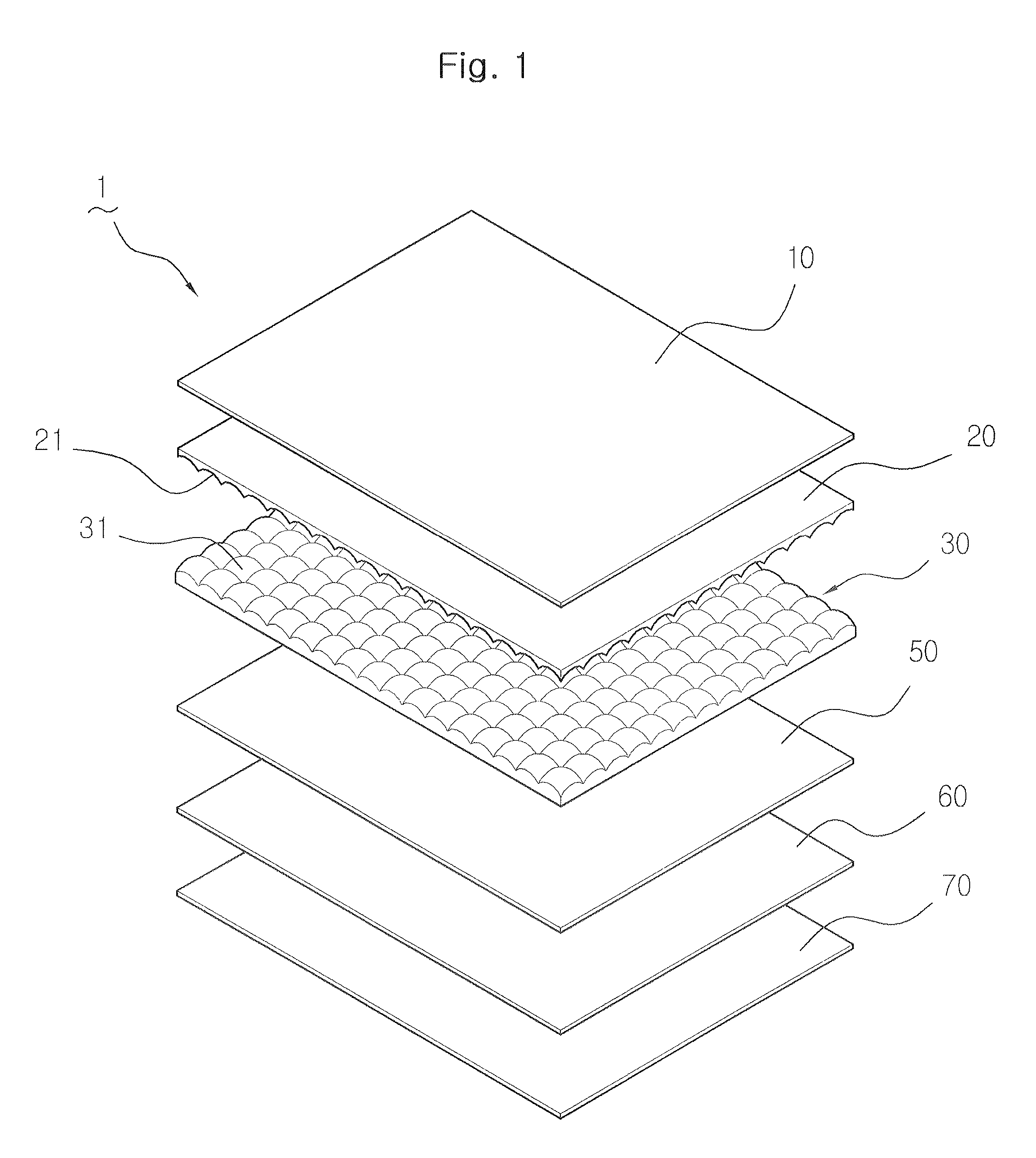

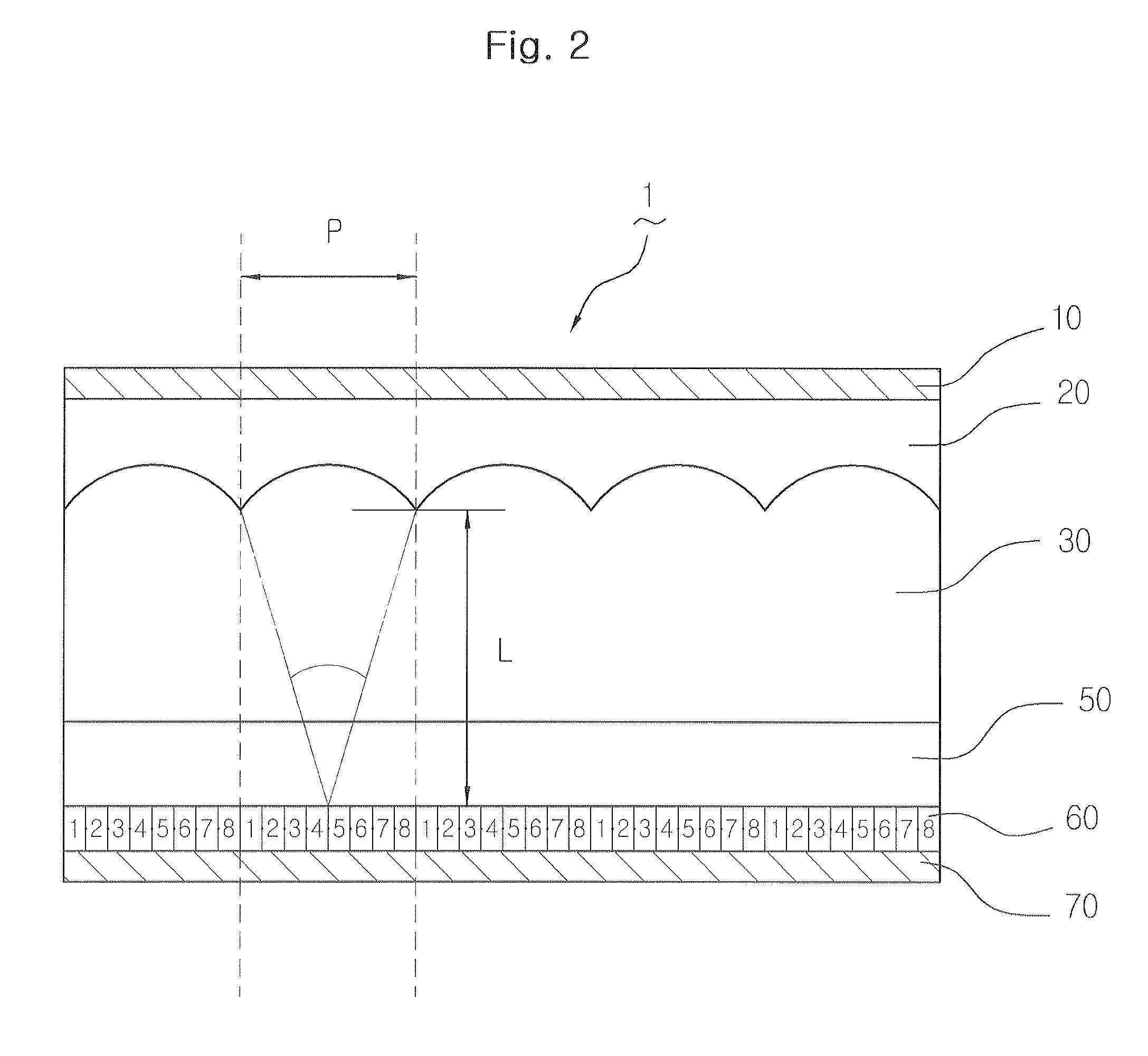

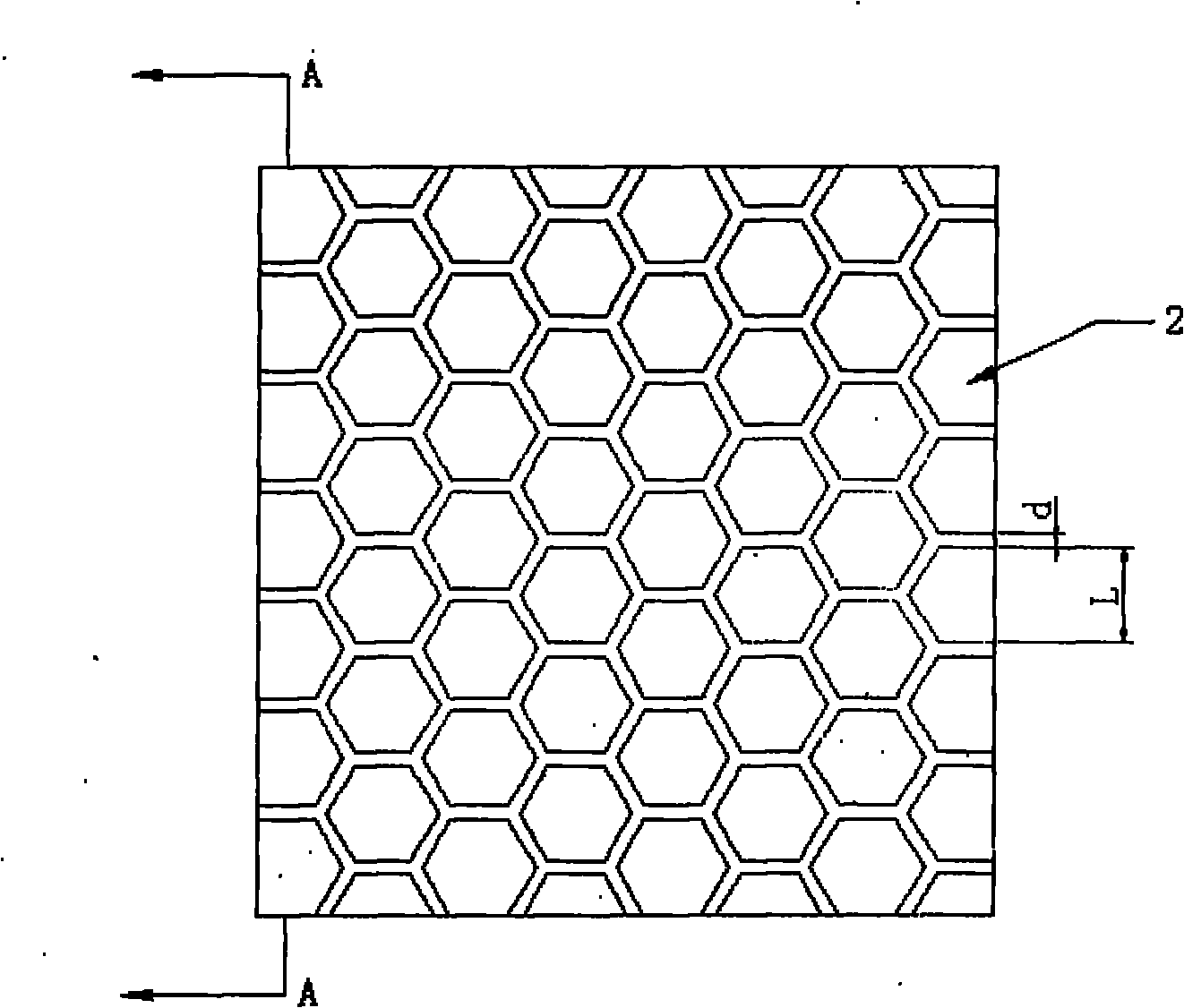

Plane lens sheet using light transmission rate difference

InactiveUS7394596B1High resolutionGood colorDiffusing elementsProjectorsIntegral photographyLenticular lens

Disclosed herein is a plane lens sheet using a light transmission rate difference, which is used for stereoscopic printing for a lenticular system and an integral photography method and has a plane surface while innumerable lenses are arranged on the surface there so that it looks like a flat transparent sheet, improves the quality of stereoscopic products employing the lens sheet and facilitates the maintenance of the stereoscopic products. The plane lens sheet includes: a concave lens layer 20 and a convex lens layer 30 laminated on each other in such a manner as the adhere to each other with the same radius curvature to form a superposed lens sheet, the concave lens layer 20 and the convex lens layer 30 being made of a transparent synthetic resin and having the same lens pitch and different light transmission rates; a thin flat transparent upper protection layer 10 formed on the concave lens layer 20; a transparent layer 50 formed below the convex lens layer 30 for forming the focal length of the laminated concave lens layer and convex lens layer; and a thin flat transparent lower protection layer 70 formed below the transparent layer 50.

Owner:CHUNG HYUNIN

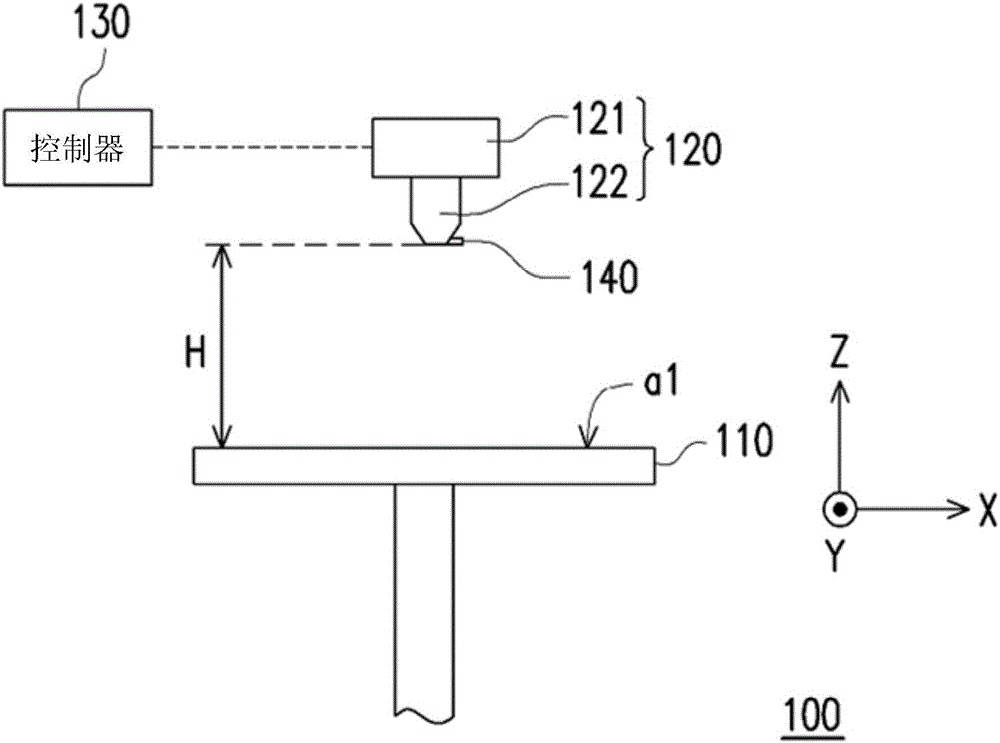

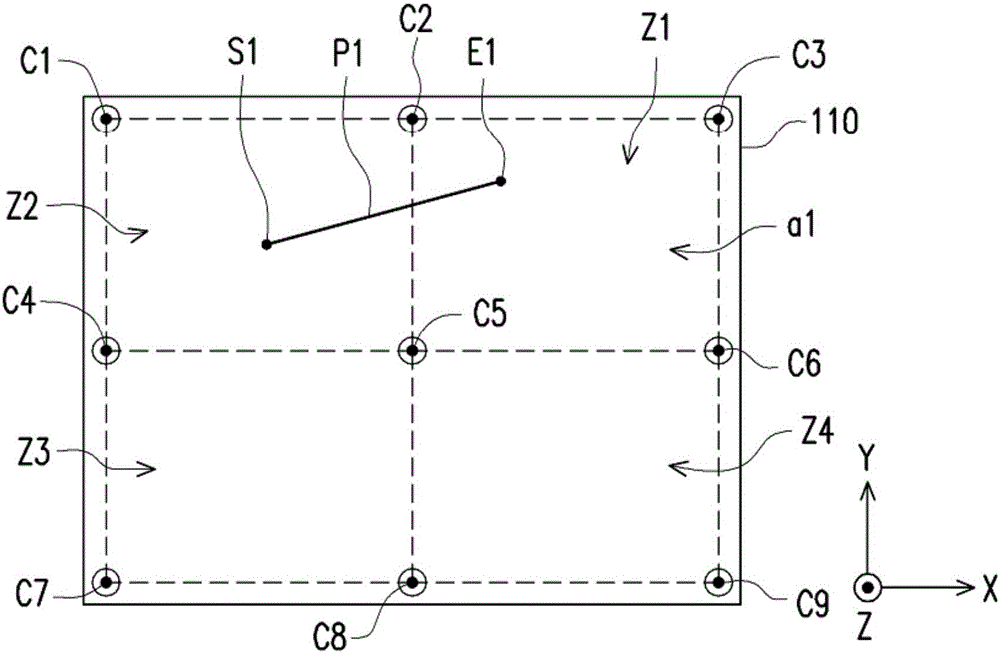

Three-dimensional printing device and printing error correcting method thereof

InactiveCN106273453AProgramme controlAdditive manufacturing apparatusBearing surfaceError correcting

The invention provides a three-dimensional printing device and a printing error correcting method thereof. A printing head of the three-dimensional printing device is suitable for moving on a datum plane along at least one linear printing path, and a formed material is fed out at the same time so that all laminated articles can be formed on a bearing surface of a platform. If the path distance of the linear printing path is larger than a threshold value, a first compensation value of the starting node and a second compensation value of the ending node are calculated according to the linear compensation relation corresponding to a plurality of first class areas of the bearing surface. If the path distance of the linear printing path is not larger than the threshold value, a common compensation value is determined according to at least one of a plurality of second class areas corresponding to the starting node and the ending node. According to the three-dimensional printing device and the printing error correcting method thereof, the printing heights of all printing nodes can be further adjusted according to the actual state of the platform, and thus the printing quality is effectively improved.

Owner:XYZPRINTING +2

Cigarette packet whose patten and characters have three-dimensional visual effect and its production method

InactiveCN1460605AWith stereoscopic effectThree-dimensionalTobacco pipesLight effect designsSurface patternGrating

The present invention relates to a cigarette packet whose surface pattern and character have stereoscopic vision effect and its production method. It is made up by printing pattern and characters on 150I pi-200I pi line grating material, and its production method includes the following steps: (1) selecting pattern and characters; (2) using special software to treat the pattern and characters; (3). making printing file; (4) setting type; (5). colour-separating, screen-placing and making plate; (6). printing; and (7). die-cutting.

Owner:YUNNAN QIAOTONG PACKAGE PRINTING

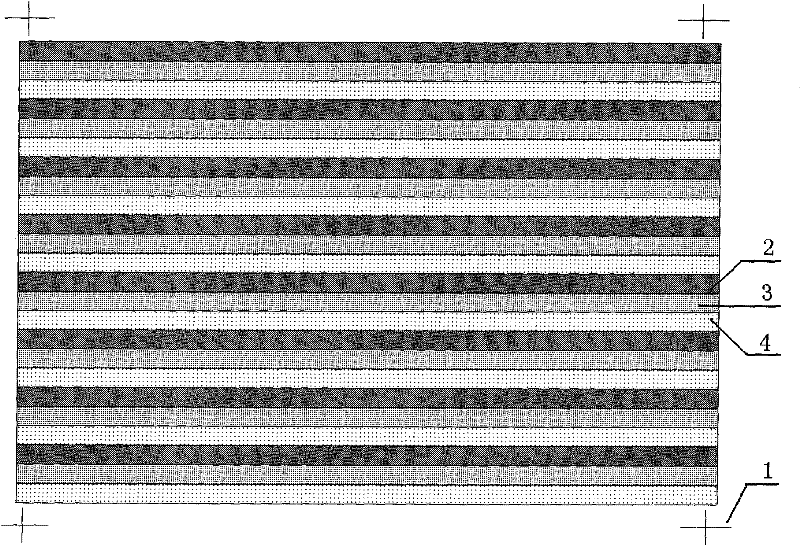

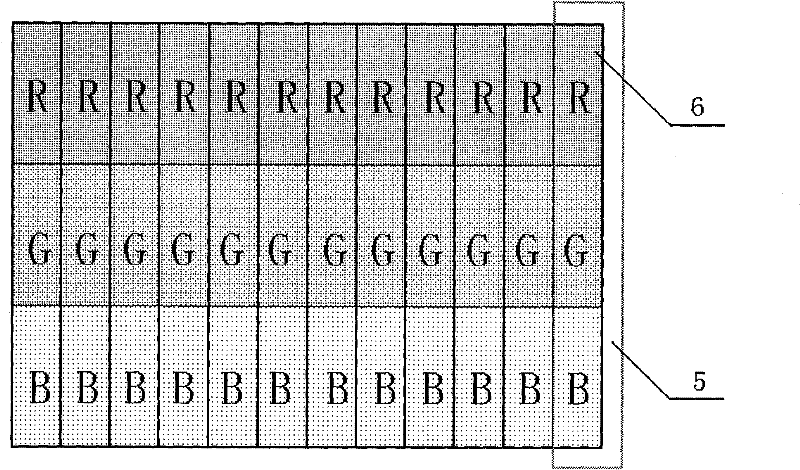

Single color printing method for colored three-dimensional image

InactiveCN102241207AGuaranteed independenceImprove vividnessPattern printingColor printingMonochrome Image

The invention discloses a single color printing method for a colored three-dimensional image. The method comprises the following steps of: recombining red-green-blue (RGB) three color components of a three-dimensional image to form a single color image; outputting the single color image to a printing plate; and overprinting to an RGB color plate to form a colored image which presents a distinct clear three-dimensional image under the irradiation of a backlight source, wherein the RGB color plate comprises periodically-distributed red (R), green (G) and blue (B) lines and overprinting marks. By the three-dimensional printing method provided by the invention, three-dimension obscuring and giddy feeling which are caused by inaccurate overprinting during four color printing are prevented, the independence of pixels is ensured, the vividness of colors is improved, the stereoscopic impression and the definition of pictures can be substantially improved, and the requirements of low cost and batch production of three-dimensional lamp box sheets are met simultaneously.

Owner:BEIJING KANGDEXIN 3D TECH

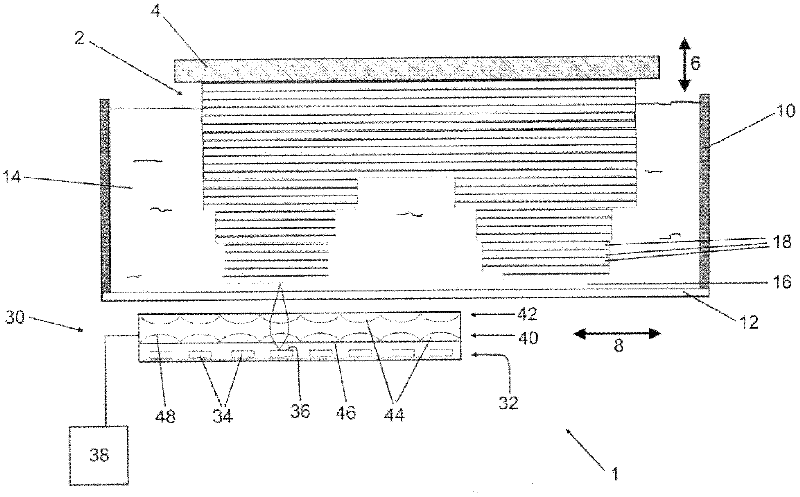

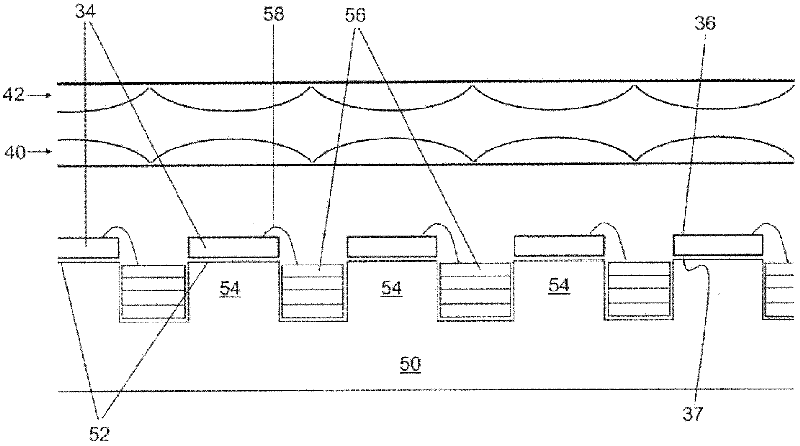

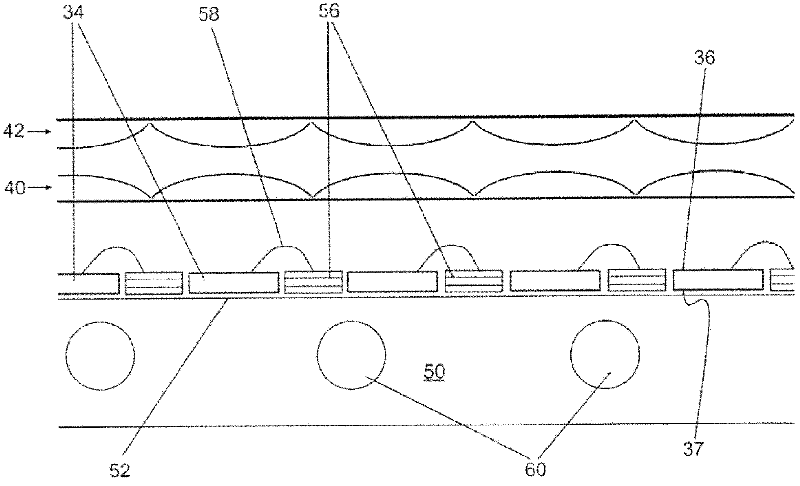

Lighting system for three-dimensional printing equipment

The present invention discloses an illumination system (30), comprising: - a plurality of light-emitting diodes (LEDs) (34), each LED having at least a first, light-emitting surface (36) and a second surface (37), at least one of the first and the second surface being substantially flat; - a plurality of electrical pathways (56), selectively connected to the respective LEDs, such that each LED can be individually controlled; and -a levelling surface (46, 52), wherein the levelling surface is substantially flat and in levelling contact with the at least one substantially flat surface (37, 36) of each LED, such that a two-dimensional array of LEDs extends in a plane parallel to the levelling surface.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

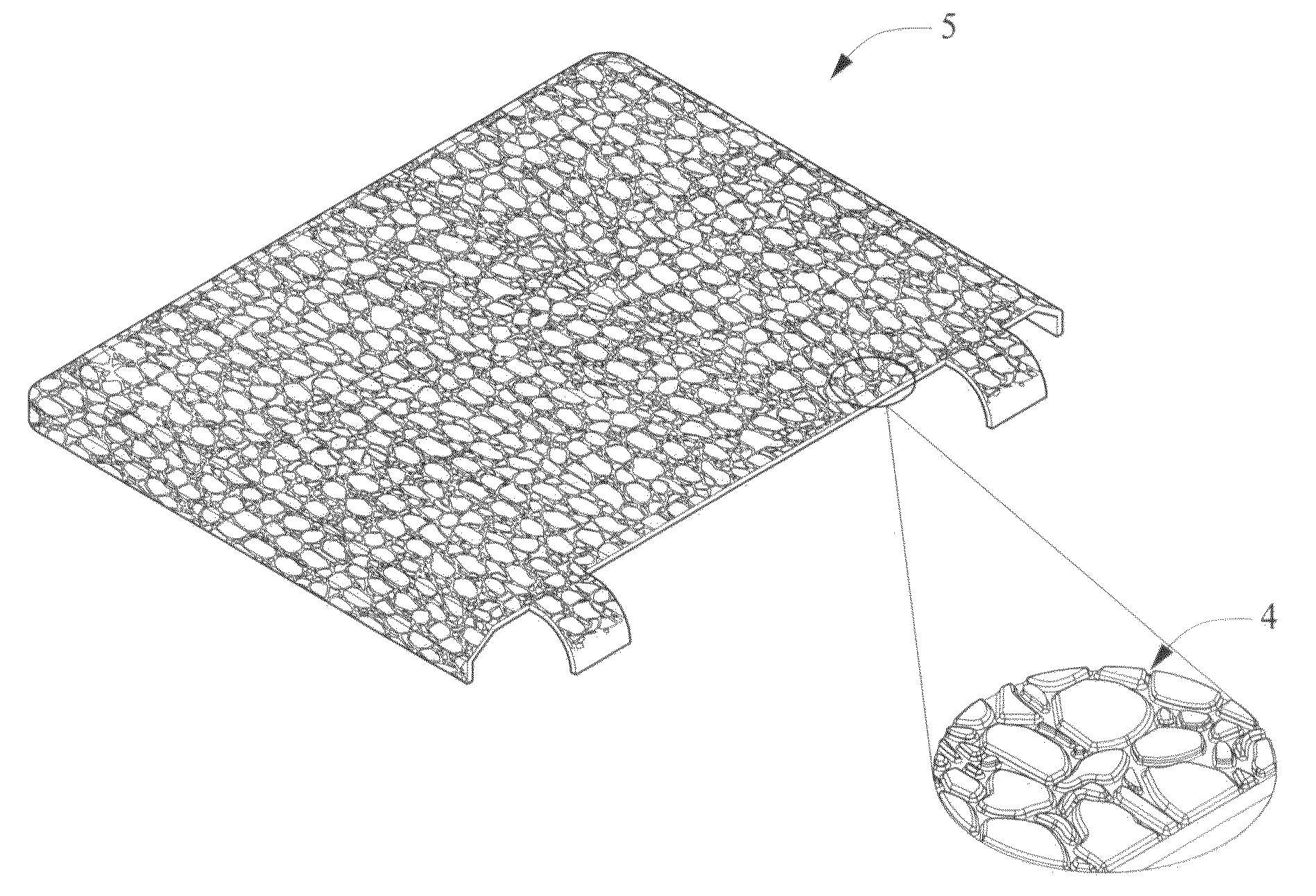

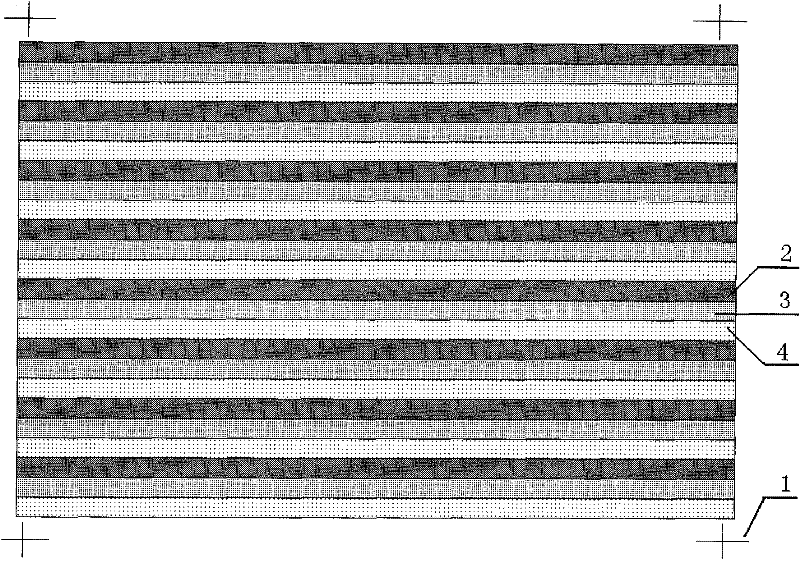

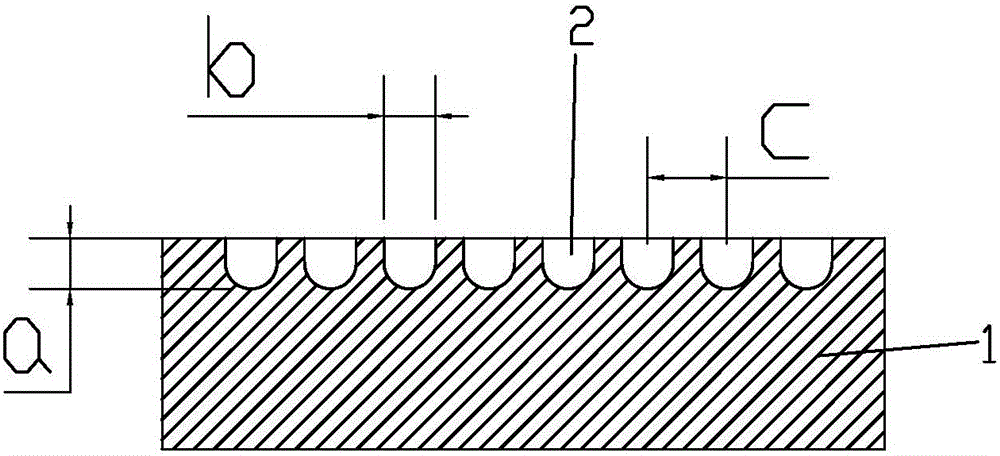

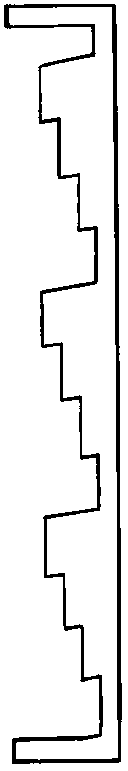

Printing technique for showing three-dimensional visual effect

InactiveCN102463756AEliminate deformationReduce scrap ratePattern printingOther printing apparatusGratingEngineering

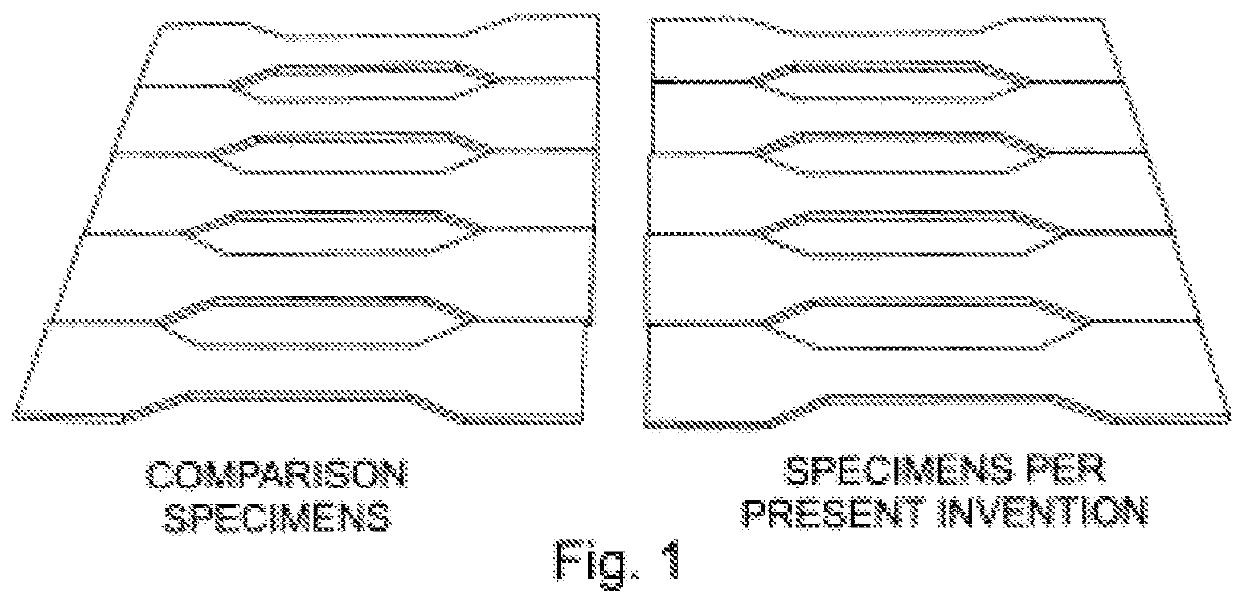

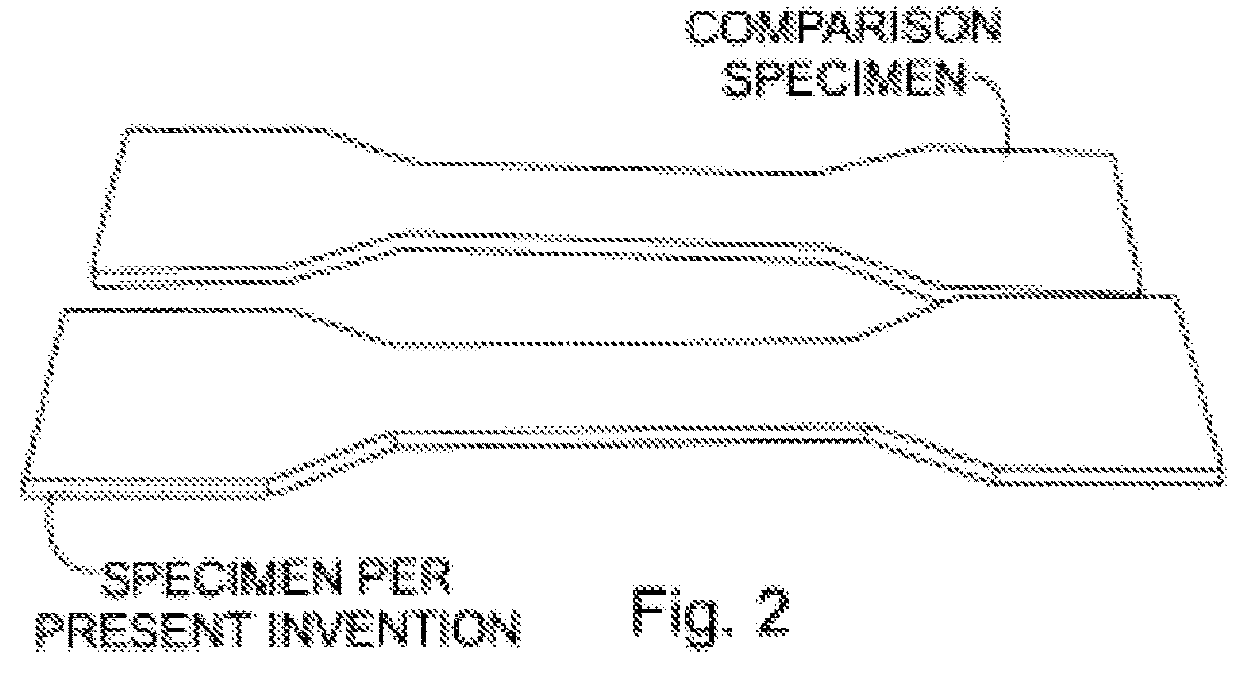

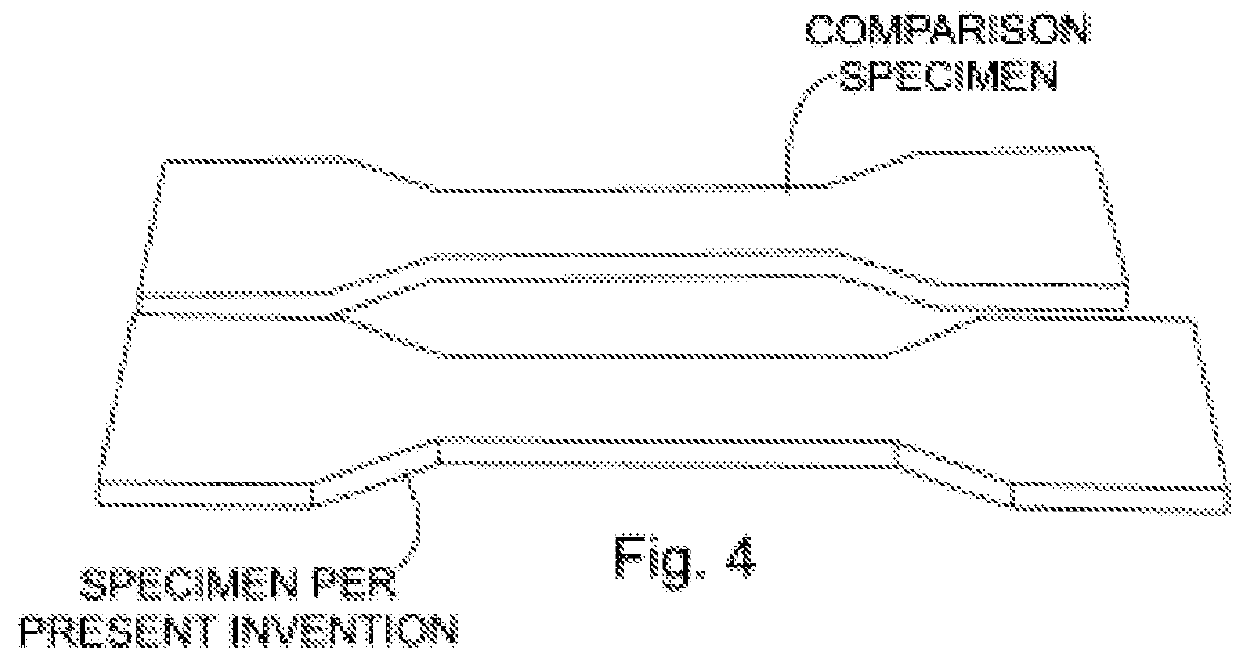

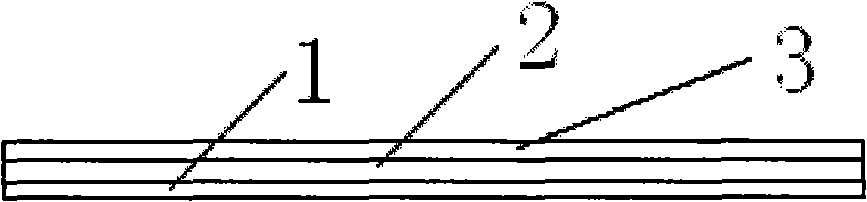

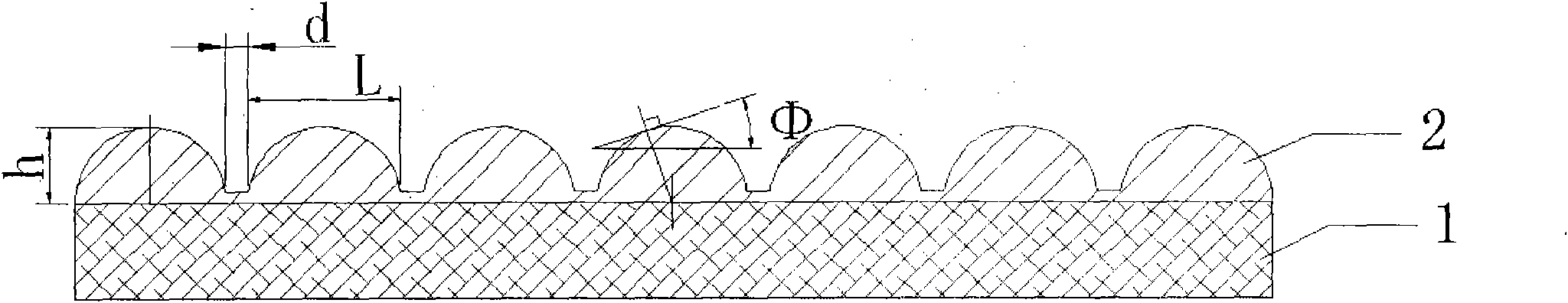

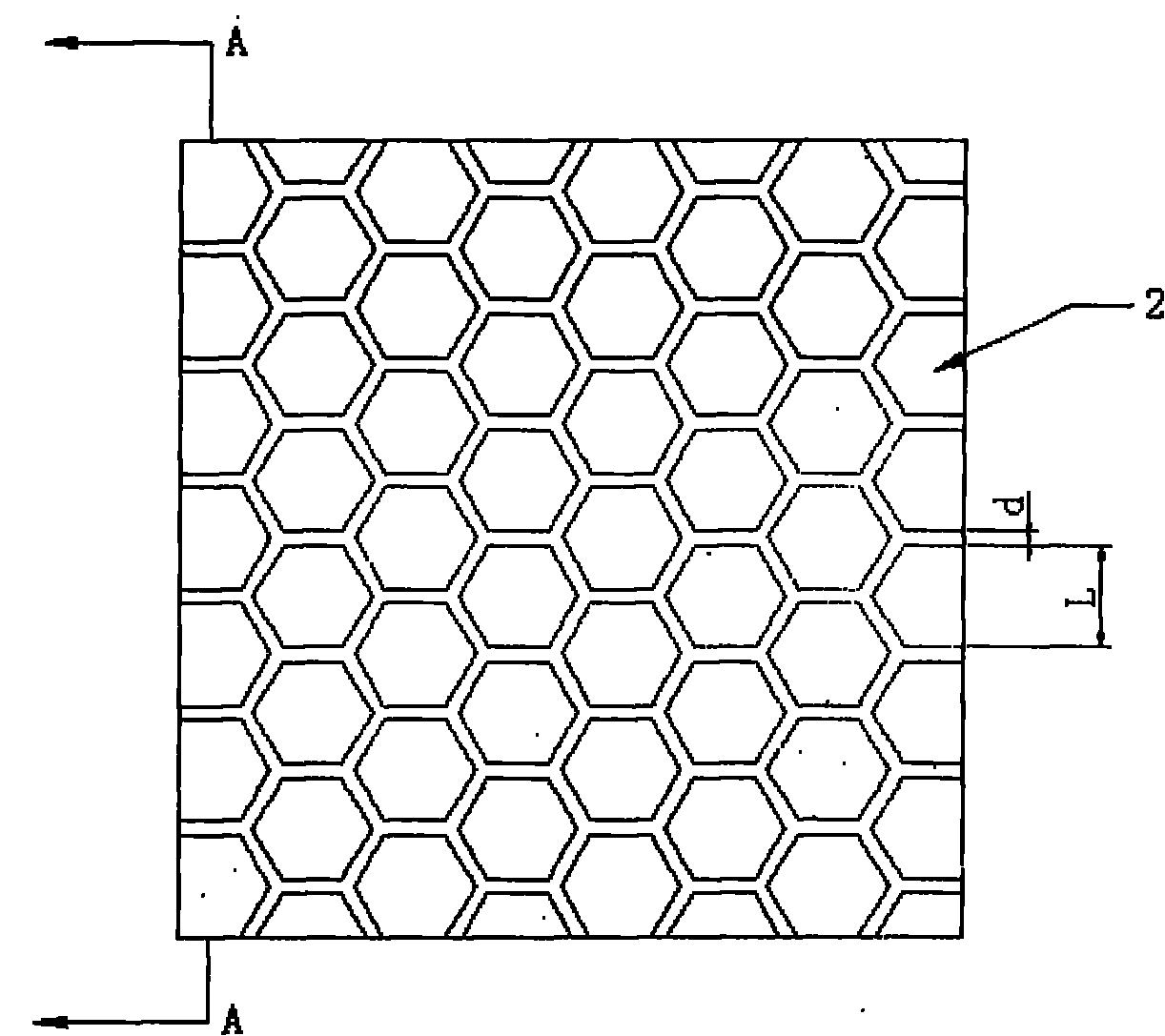

The invention discloses a printing technique for showing a three-dimensional visual effect, and relates to a printing technique for directly showing the three-dimensional visual effect of patterns and characters. The printing technique needs to solve the following two problems: (1) eliminating the deformation of dot-like gratings formed by hot-pressing in order to decrease the reject rate and increase the production benefit; (2) reducing the application cost of three-dimensional printing. In order to solve the technical problems, the printing technique is implemented by the following technical scheme: the printing technique for showing the three-dimensional visual effect first prints synthesized three-dimensional patterns and characters on a printing stock (1), transparent varnish is coated on the surfaces of the patterns and the characters, and is pressed by a dot-like grating die matched with the patterns and the characters, so that an equidistant dot-like grating (2) is formed on the transparent material, and thereby the patterns and the characters show the three-dimensional visual effect. The printing technique is mainly applied to product packages, books, periodicals, advertisement and the like directly showing the three-dimensional visual effect of the patterns and characters.

Owner:罗俊平 +1

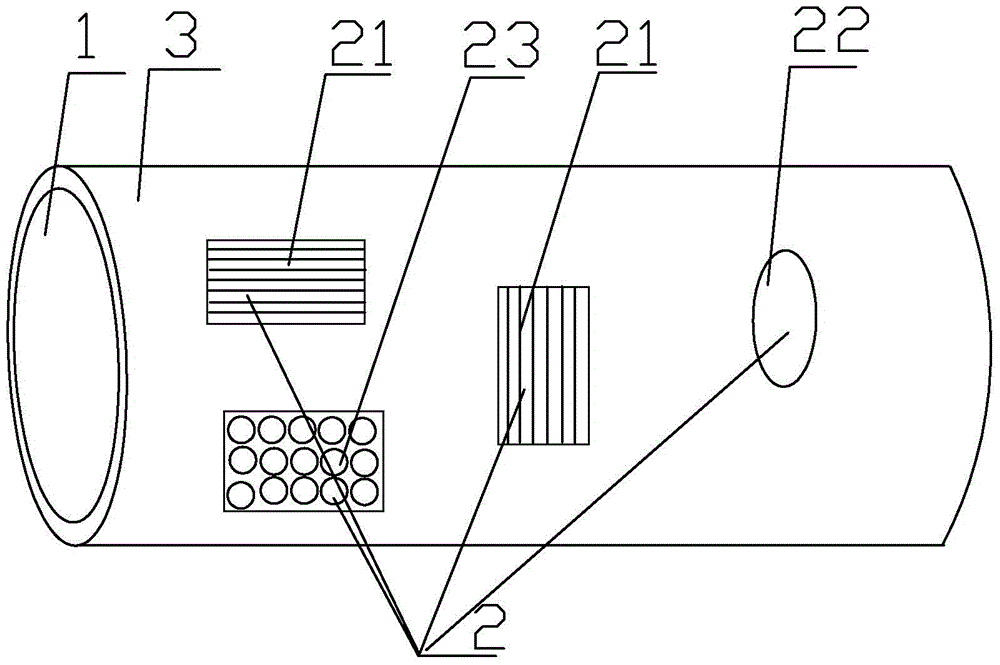

Optical roller assembly with local optical effect patterns and local optical sheet manufacturing method

InactiveCN104002543AExquisite appearanceImprove anti-counterfeiting effectPattern printingRotary pressesEngineeringGrating pattern

The invention relates to the technical field of optical film production, and particularly discloses a optical roller assembly with local optical effect patterns and a method for manufacturing a local optical sheet and a three-dimensional printed pattern product. The optical roller assembly comprises a roller, and the surface of the roller is wrapped by or sleeved with a template or a sleeve with the local optical effect patterns. The local optical effect patterns include one or more of a column-shaped or dot grating pattern, a micro optical lens pressed pattern and a laser pressed pattern. Transverse gratings and longitudinal gratings in the column-shaped grating pattern are distributed in the same area or different areas. After the roller is bonded by means of the template or the sleeve with the optical effect patterns, the local optical effect patterns can be pressed on transparent sheets, and then patterns are positioned and printed on the local effect patterns to obtain exquisite products with high visuality. The optical roller assembly and the manufacturing method have the advantages that cost is low, efficiency is high and the method is easy and convenient to complement.

Owner:EXTREME LENTICULAR PRINTING FACTORY

Three-dimensional printing method

ActiveUS9434109B2Low costShorten production timeAdditive manufacturing apparatus3D object support structuresEngineering3 dimensional printing

A three-dimensional printing method for forming a three-dimensional object on a base is provided. The method comprises providing a model library comprising at least one supporting member, selecting the at least one supporting member from the model library and disposing the at least one supporting member onto the base. The three-dimensional object is printed over the base and the at the least supporting member, and the three-dimensional object has an overhanging portion relative to the base and the at least one supporting member is filled between the overhanging portion and the base.

Owner:XYZPRINTING +2

Three-dimensional printing technology and three-dimensional printed matter

InactiveCN106965581ALower requirementWide variety of sourcesPattern printingPolymer scienceRoom temperature

The invention discloses a three-dimensional printing technology and a three-dimensional printed matter, and belongs to the technical field of three-dimensional printing. According to the technical scheme, the three-dimensional printing technology is characterized by comprising the following steps in sequence that (1) printed materials with printed image-text are took, and the image-text part is sprayed with fine powder in a wet state so that printing powdered products can be obtained; (2) the printing powdered products are dried at 350-550 DEG C for 10-20 min, then the printing powdered products are conducted high temperature curing at 550-650 DEG C for 5-20 min, and prefabricated matters are obtained; and (3) the prefabricated matters are cooled at the room temperature, and the three-dimensional printed matter is obtained. The three-dimensional printing technology and the three-dimensional printed matter have the beneficial effects that required devices are low in investment, simple in method, easy to operate, capable of saving labor force, capable of being not limited by the printing method and completed off-line with a printing press, capable of saving space, low in cost and suitable for large-scale promotion; and the obtained three-dimensional printed matter is good in three-dimensional effect, clear in images, high in added value and good in anti-fake capacity.

Owner:北京奇良海德印刷股份有限公司

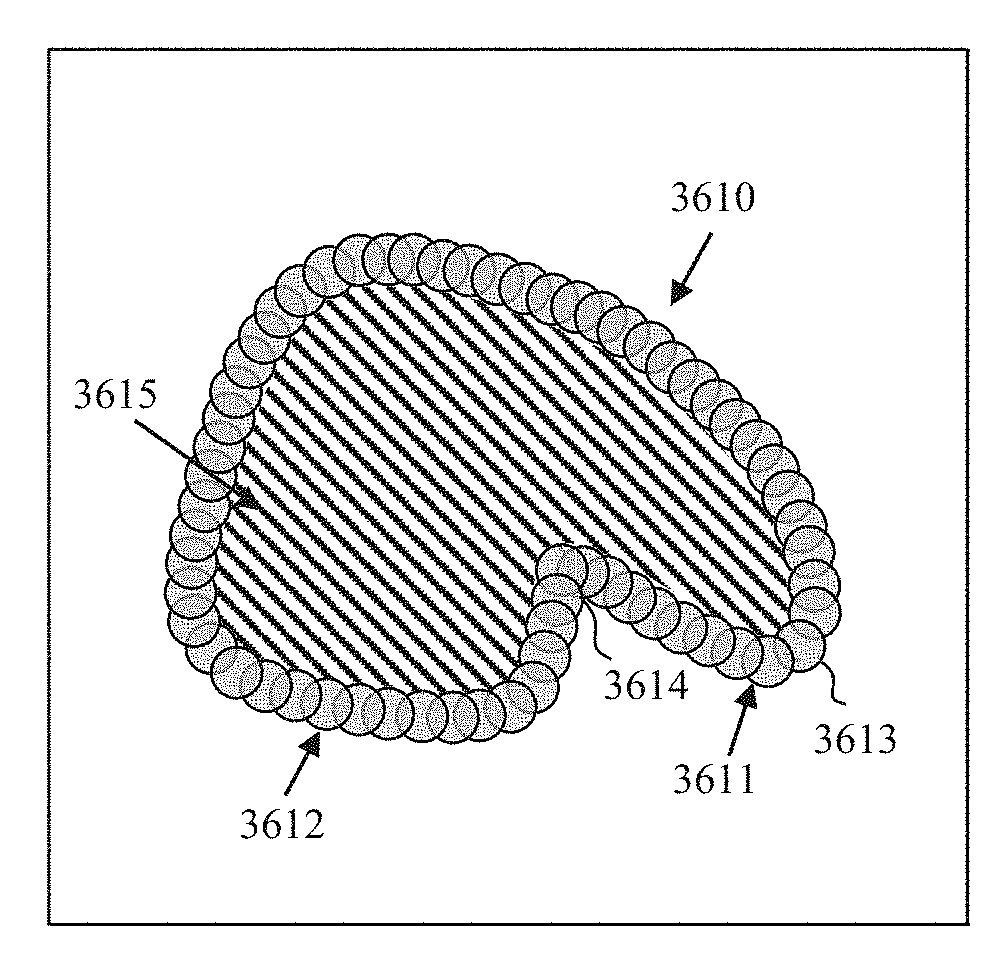

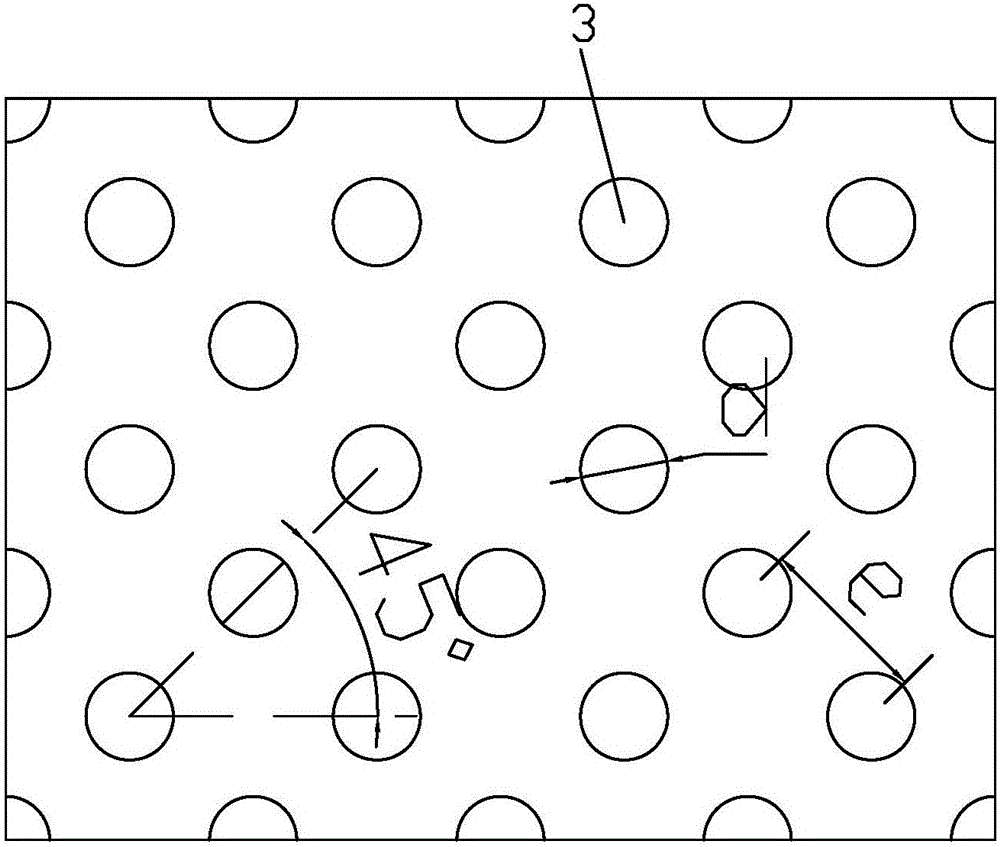

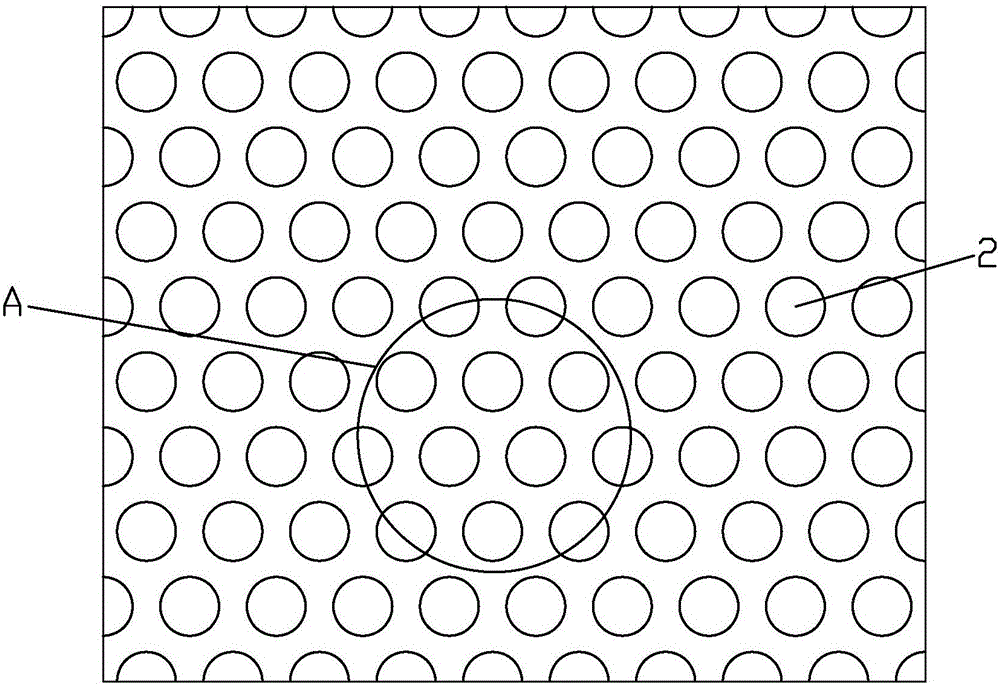

Method for carrying out three-dimensional printing by utilizing round-dot optical grating

ActiveCN105882182ALow costEasy to operatePattern printingPolyurea/polyurethane coatingsGratingSheet film

The invention discloses a method for carrying out three-dimensional printing by utilizing a round-dot optical grating. According to the technical scheme adopted by the invention, the key point of the method comprises the following steps: drawing a printed pattern by virtue of graphics software and platemaking, and offset-printing a colorful pattern and a local space pattern on the back surface of a film; and offset-printing UV base oil on the front surface of the film, and gravure-printing UV face oil through a gravure-printing roller, and the like. According to the invention, the printing method capable of realizing local three-dimensional printing effect does not need an optical grating plate, only needs a common transparent film, limitation on thickness and dimension of the transparent film is avoided, and 3D effect can be formed after printing, so that the cost is low, the operation is simple, and the flexibility is high. Common pre-printing process software is not needed to be used, additional investment is not needed, the popularization is easy, and the graphic processing is very simple.

Owner:ZRP PRINTING GRP CO LTD

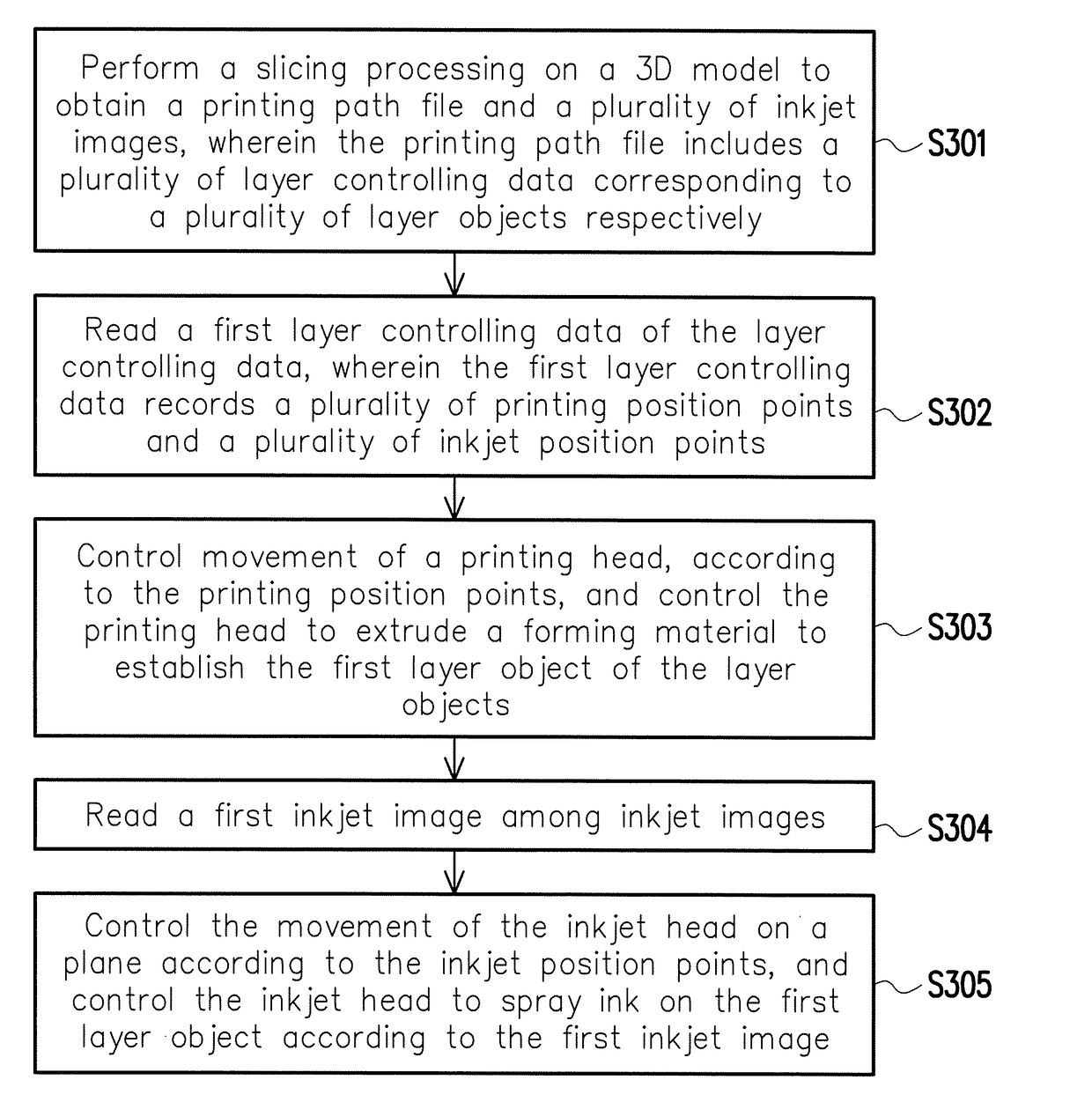

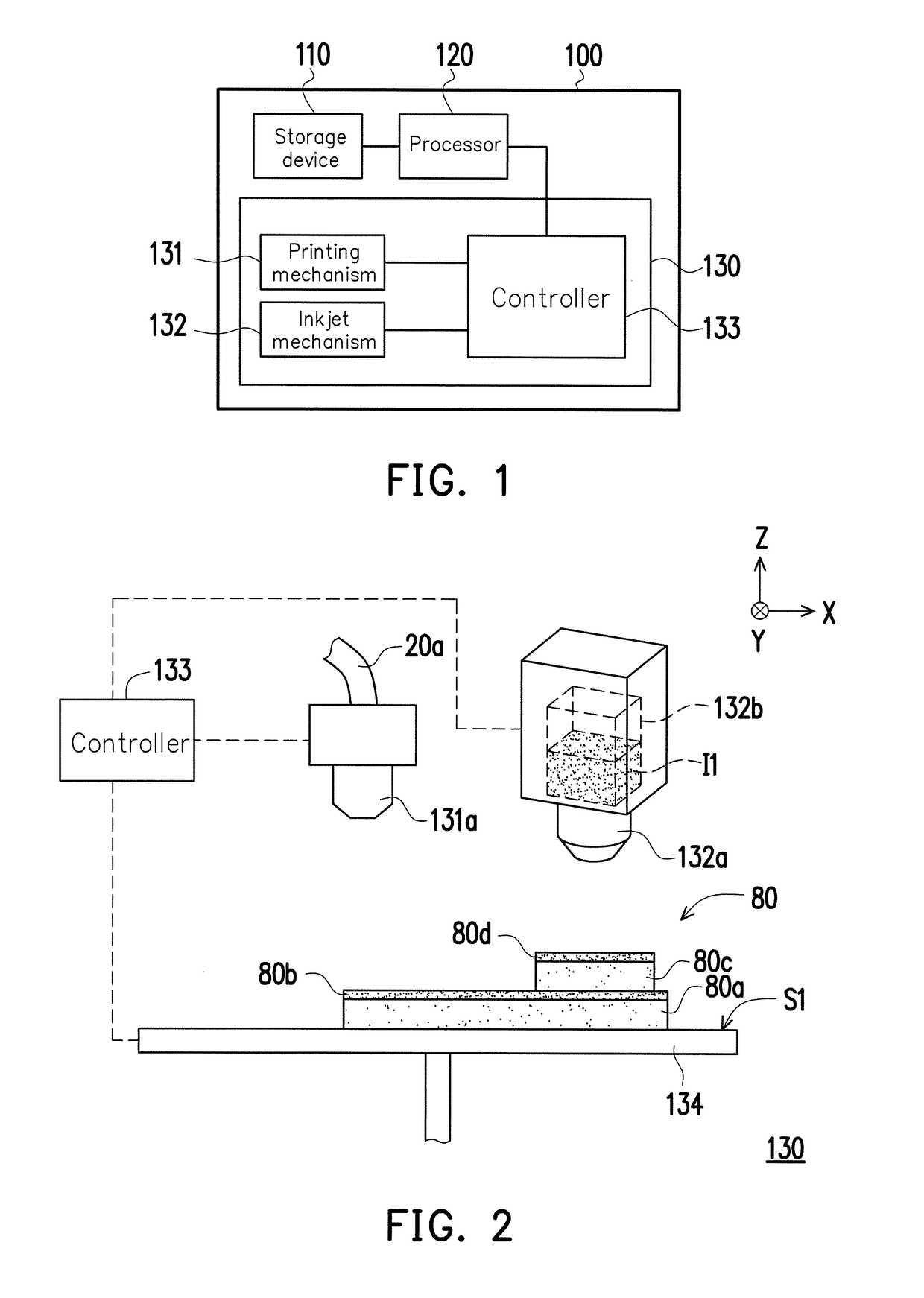

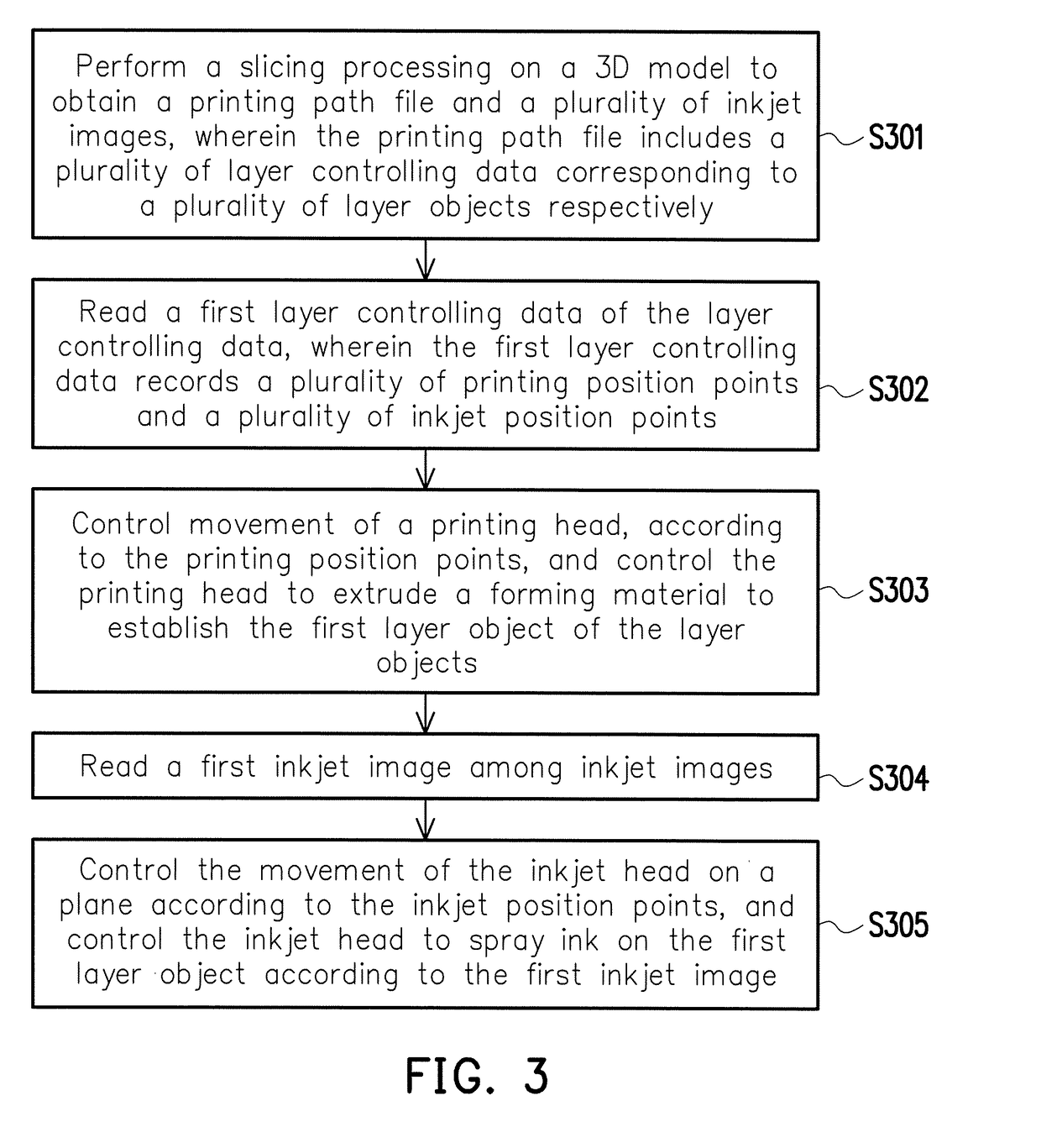

Color three-dimensional printing method and three-dimensional printing equipment

InactiveUS20180311902A1Improve diversity and aestheticGood color propertiesProgramme controlAdditive manufacturing apparatusEngineeringVolumetric printing

A color three-dimensional printing method and a three-dimensional printing equipment are provided. A slicing processing is performed on a 3D model to obtain a printing path file and a plurality of inkjet images. A first layer controlling data in the printing path file is read, wherein the first layer controlling data records a plurality of printing position points and a plurality of inkjet position points. Movement of a printing head is controlled according to the printing position points, and the printing head is controlled to extrude a forming material, to establish a first layer object. A first inkjet image among the inkjet images is read. Movement of an inkjet head on a plane is controlled according to the inkjet position points, and the inkjet head is controlled to spray the ink on the first layer object according to the first inkjet image.

Owner:XYZPRINTING +1

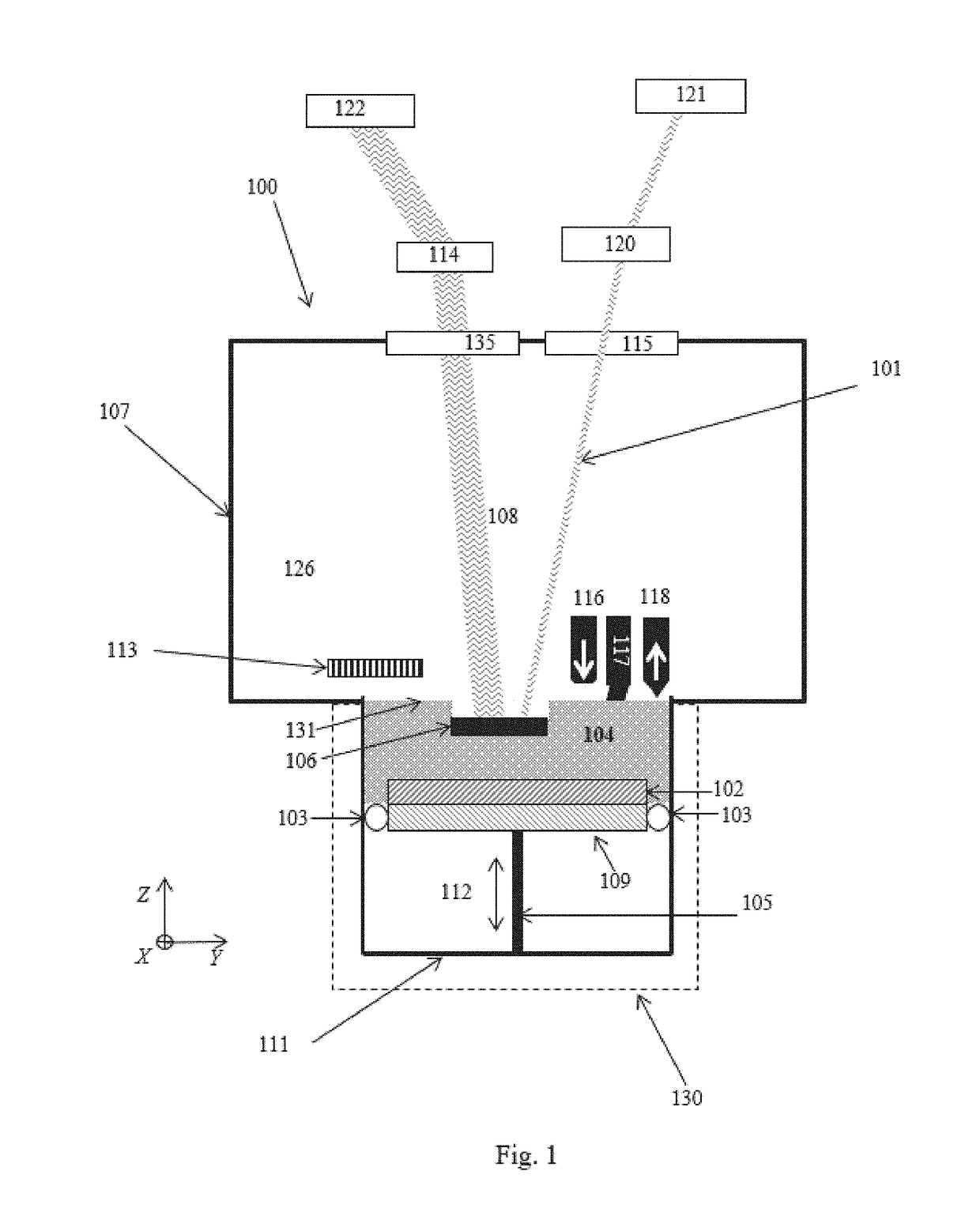

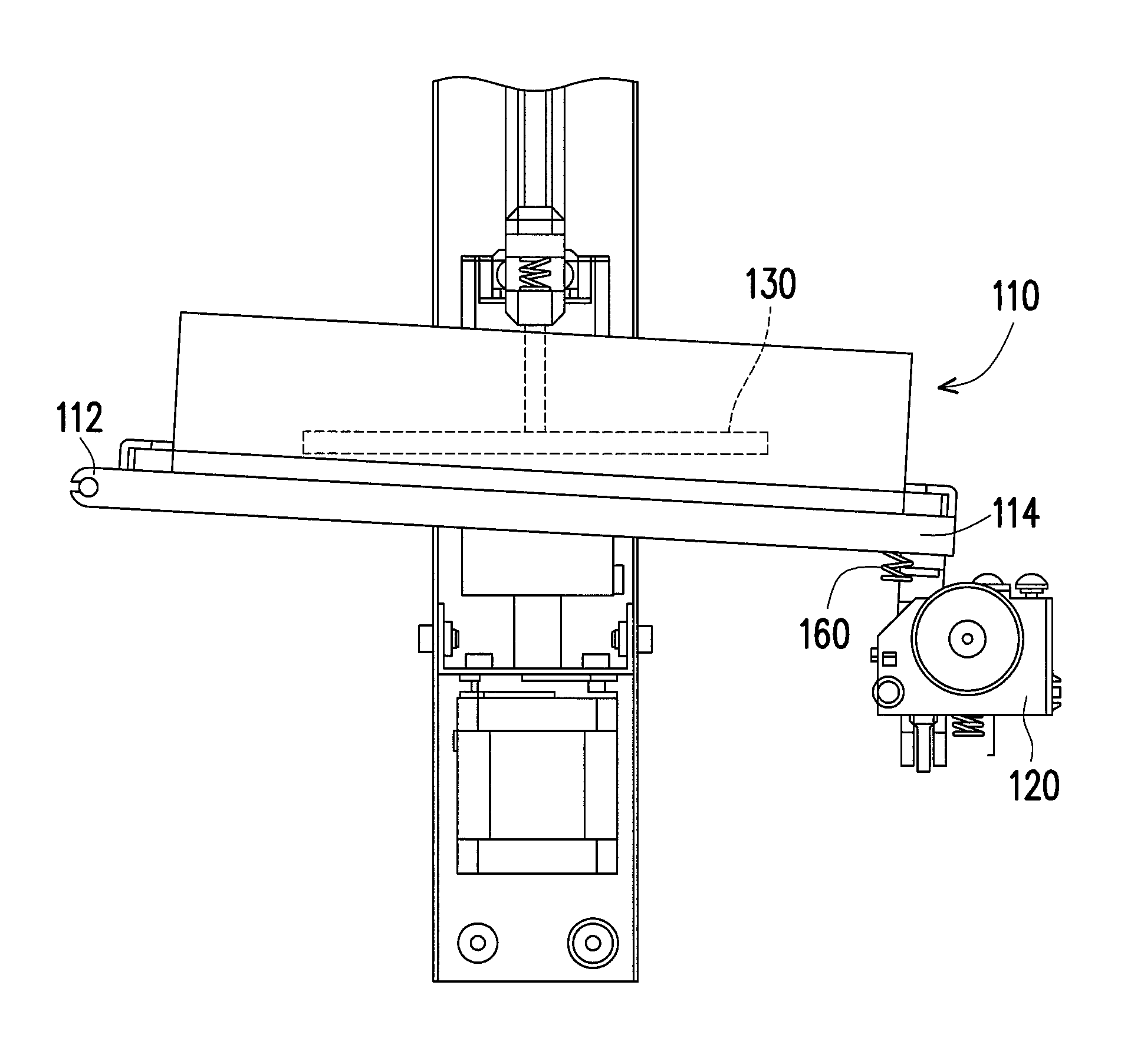

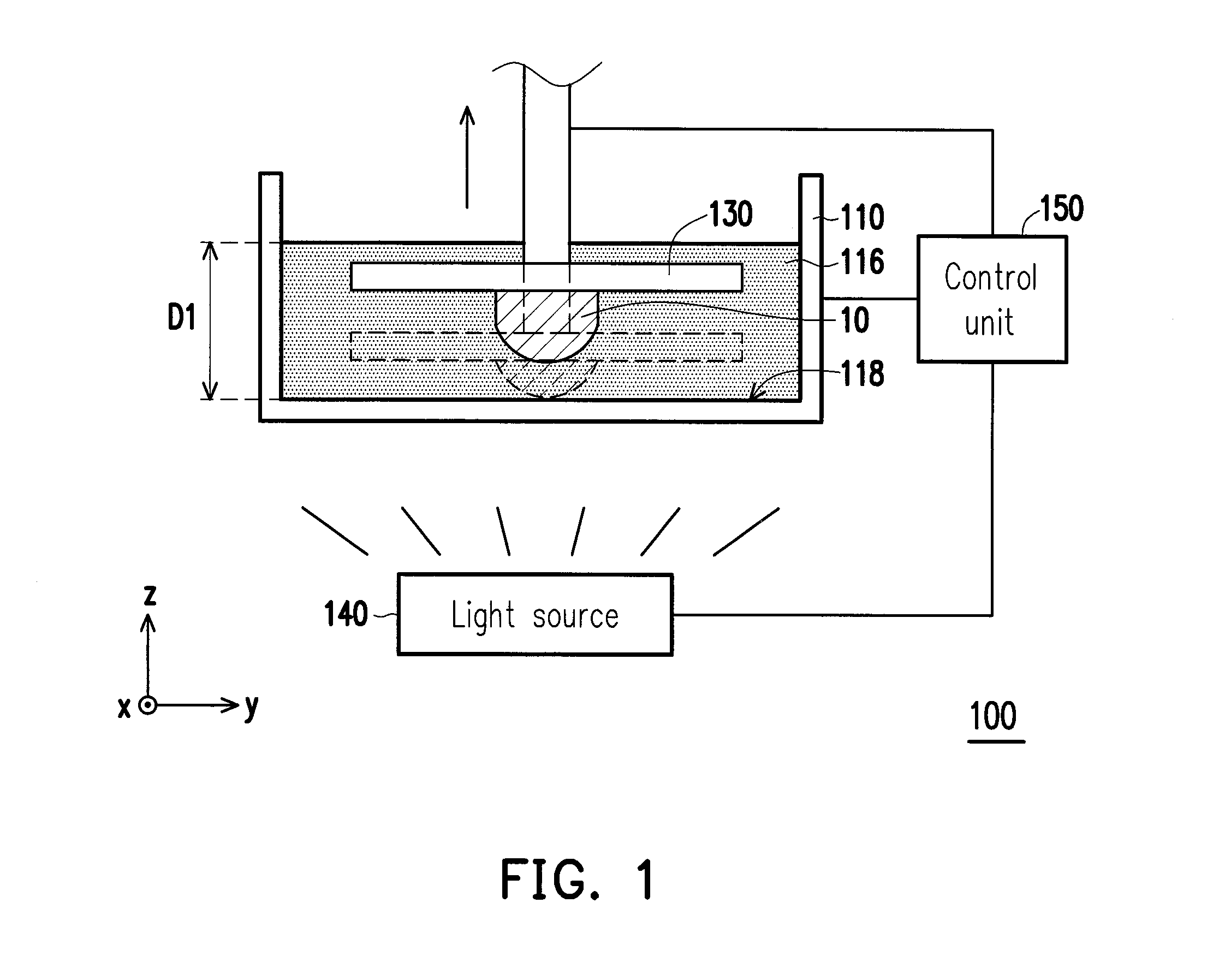

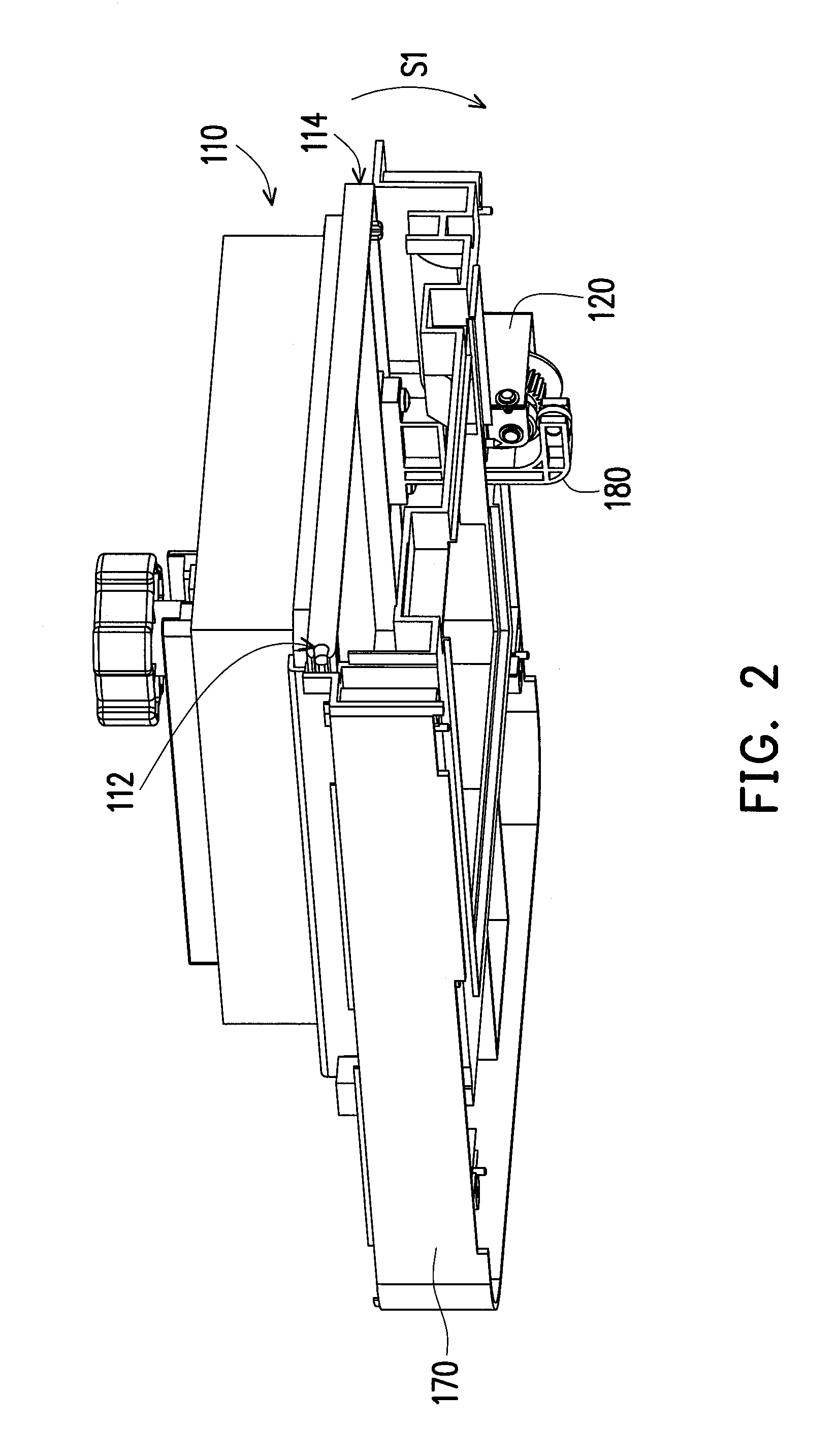

Three-dimensional printing apparatus

ActiveUS9346217B2Improve printing qualityEasy to separateManufacturing driving means3D object support structuresCamVolumetric printing

A three-dimensional printing apparatus including a swing tank containing a liquid formation material, a swing mechanism, an elevating platform, a light source and a control unit is provided. The swing tank includes a pivot side and a swing side adapted to be swung about the pivot side. The swing mechanism includes a cam and a driving motor. The cam leans against the swing side for swinging the same. The elevating platform and the light source are respectively disposed above and below the swing tank. The control unit controls the elevating platform to immerge into the liquid formation material. The light source cures the liquid formation material between the elevating platform and the bottom of the swing tank. The control unit then controls the swing mechanism to swing the swing side, so the cured liquid formation material is separated from the bottom and located on the elevating platform.

Owner:XYZPRINTING +2

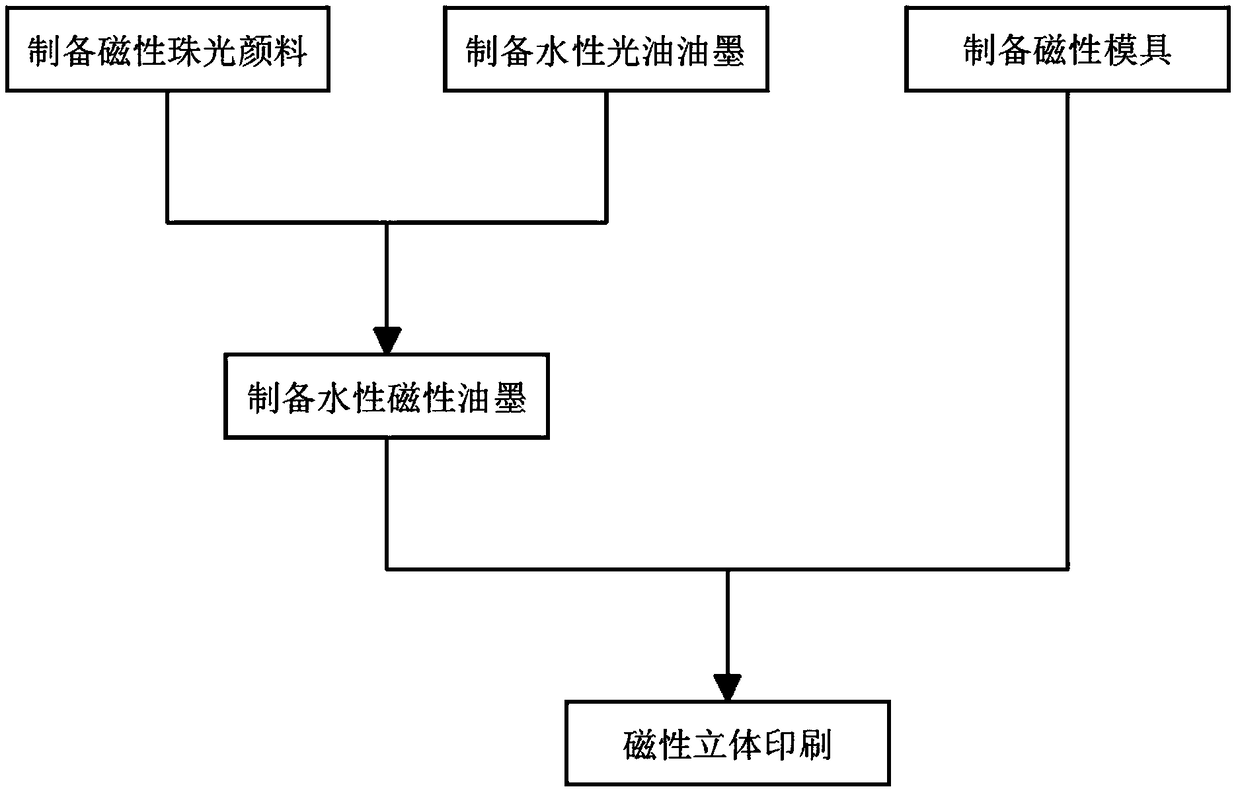

Magnetic three-dimensional printing technology

ActiveCN109094231AGood three-dimensionalOvercoming Volatile DefectsPattern printingWater basedEngineering

The invention relates to a printing technology and discloses a magnetic three-dimensional printing technology. The magnetic three-dimensional printing technology mainly comprises the following steps that S1, water-based polishing oil is evenly printed on a printed material to form a water-based polishing oil layer; S2, water-based color ink is evenly printed on the water-based polishing oil layerto form a water-based color ink layer; S3, after the water-based color ink is dried, water-based magnetic ink is evenly printed on the water-based color ink layer, and the printed material is printed;and S4, a magnetic mold is positioned on the upper portion of the printed material in a suspended mode, thus iron-containing magnetic matter in the water-based magnetic ink is attracted by magnetic force of the magnetic mold to move, and finally, a three-dimensional pattern is formed. According to the magnetic three-dimensional printing technology, the three-dimensional pattern can be printed; and the defect that ink is prone to volatilization in the prior art can further be overcome, and thus generation of volatile organic compounds (VOC) is avoided.

Owner:中山市三盛化工科技有限公司

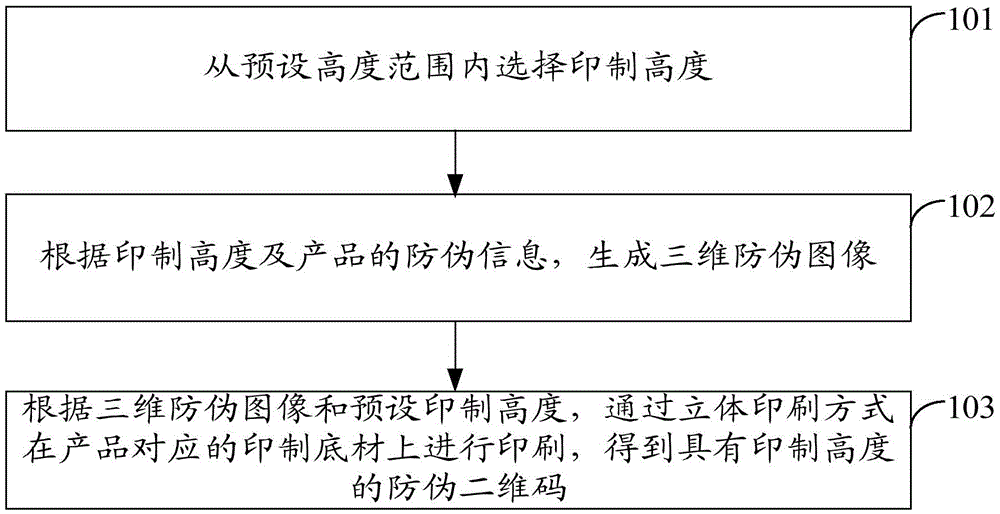

Printing method and device for anti-counterfeiting two-dimensional code with printing height

ActiveCN105538896AHigh measurement difficultyReduce reproducibilityPattern printingRotary pressesEngineeringVolumetric printing

Owner:SOUTH CHINA UNIV OF TECH +1

Simulation plate manufacturing technology taking natural material as base material and synchronous stereoscopic printing technology for surface texture and color

InactiveCN102501391AReduce manufacturing costReduce sizePattern printingManufacturing technologyRoll forming

The invention discloses a simulation plate manufacturing technology taking natural material as a base material and a synchronous stereoscopic printing technology for surface texture and color. The manufacturing technology comprises the following steps of: making a silica gel mould by taking the natural material as a mould seed; rolling and forming slurry on a plate forming machine before curing to obtain a plate with stereoscopic material texture on the surface; and performing stereoscopic printing on the surface texture and color: taking the color and texture of the natural material mould seed on a large scanner, then editing and processing the taken pattern on a computer, and placing the plate on a large digital spray painting device for spray painting to obtain a plate consistent with the natural material in shape, texture and color. According to the invention, the product has the advantages that: the shape and texture of a real object can be completely and vividly copied by use of a silica gel template; natural color and texture are obtained; the plate surface has an elegant and complete effect as well as strong simulation; and as inorganic composite material is adopted, the manufacturing cost is low, and the simulation plate is easy to popularize.

Owner:TONGXIANG DIMENSIONAL MEGA DECORATING MATERIAL

Anti-fake three-dimensional printed product and manufacturing method thereof

InactiveCN103366210AReliable labelReliable markingRecord carriers used with machinesSurface layerTrademark

The invention relates to an anti-fake three-dimensional printed product and a manufacturing method thereof. The anti-fake three-dimensional printed product is characterized in that one of the sections of the anti-fake three-dimensional printed product is provided with multiple layers which are a surface layer, a middle layer and a bottom layer respectively; the bottom layer and the middle layer are respectively provided with an anti-fake coding layer, and the total thickness of all the layers is smaller than 2mm. Anti-fake trademarks, labels and marks made of the anti-fake three-dimensional printed product are quietly reliable, and therefore reliable guarantee is provided for fake prevention. The anti-fake three-dimensional printed product is wide in application range and can be applied to all walks of life as long as fake prevention is needed, such as printed bank notes, certificates (identity cards, driving licenses and passports), entrance tickets, moon cake tickets, famous cigarettes and wine, medicine and health care products, clothing shoes and hats, cosmetics, household appliances, cell pones and computers, optical disks and various well-known brands, including Xinghualou Moon Cake, West Lake Longjing Tea, Jinhua Ham, Nanjing Salted Duck, White Elephant Battery, Paradise Umbrella, Bull Electric, M&G Stationery and the like. The anti-fake three-dimensional printed product is extremely convenient to use, anti-fake codes can be arranged in carry-on cell phones, and even ordinary people can identify authenticity in one second through the cell phones.

Owner:黄丽娜

Three-dimensional printing method and decorative plate and lamp box manufactured through method

InactiveCN103722920AStereoscopic effectNot dizzyDecorative surface effectsSpecial ornamental structuresUltravioletPrinting ink

The invention relates to a three-dimensional printing method and a decorative plate and a lamp box manufactured through the method. The three-dimensional printing method includes the steps that printing is carried out on a sheet material with a concave-convex surface by means of printing ink capable of being hardened through ultraviolet rays or electron beams, so that the concave-convex appearance of the surface of the sheet after printing is maintained, the printing resolution is 5 times to 20 times of concave-convex density, and the decorative plate with a visual three-dimensional field depth effect is generated. When the sheet material with the concave-convex surface is a transparent lens material, the high-contrast decorative plate or the lamp box can be formed due to the combination of the transparent lens material and a reflective sheet material or a backlight source.

Owner:JIN YONGQUAN INTERNATIONAL TECHNOLOGIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com