Method for carrying out three-dimensional printing by utilizing round-dot optical grating

A three-dimensional printing, dot grating technology, applied in the production of special varieties of printing, printing, printing process and other directions, can solve the problems of high equipment requirements, low flexibility, high cost, and achieve simple graphics processing, easy promotion and operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

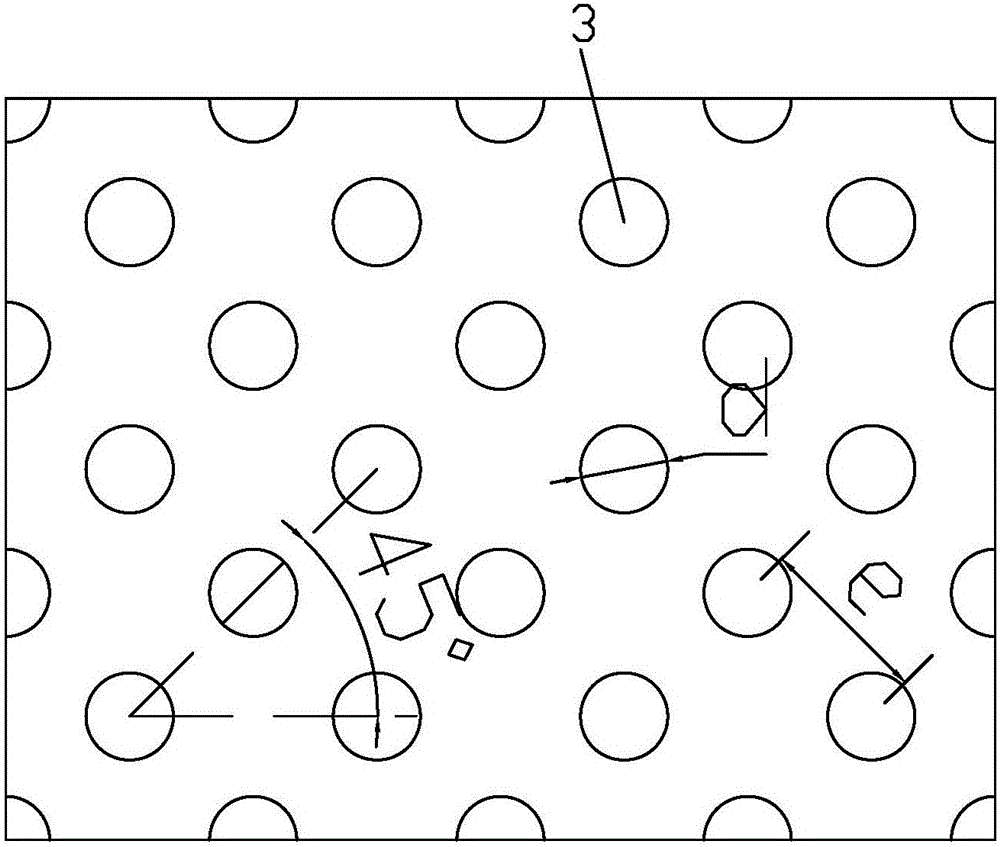

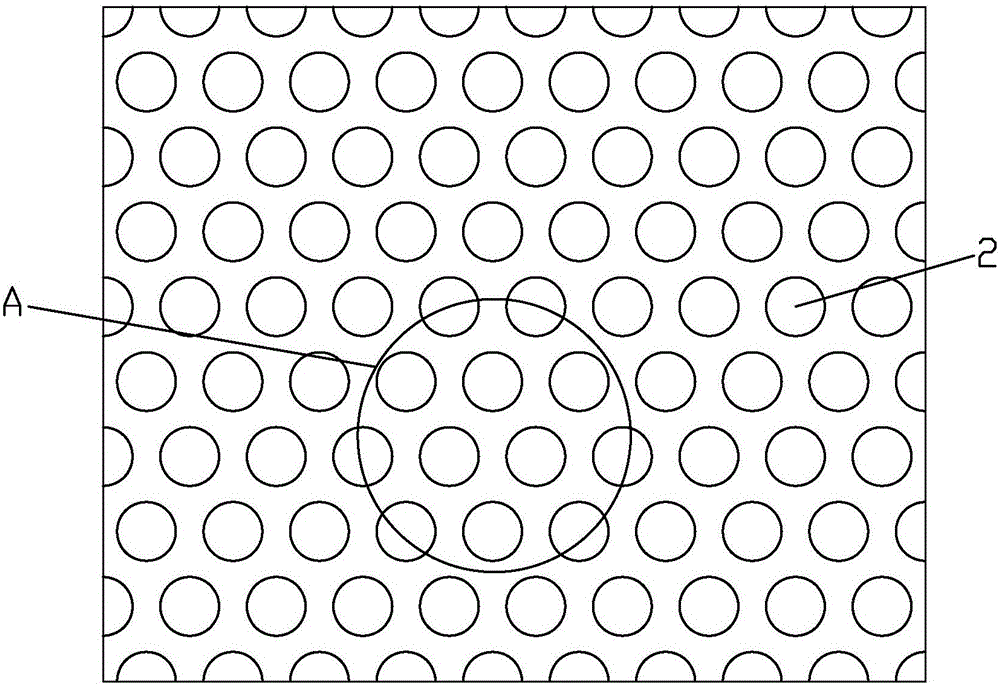

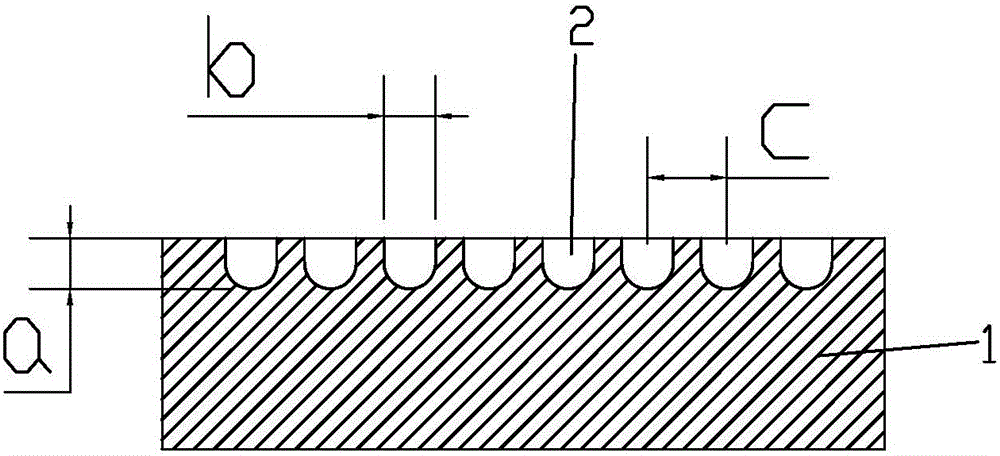

[0037] The invention is a printing technique with a local three-dimensional effect produced by using a circular dot grating. Unlike the commonly used lenticular lens grating, the lenticular lens grating has vertical stripes. The dot grating is a separate independent dot.

[0038] Dot grating is a special grating composed of several dots arranged neatly. Each dot is a tiny convex lens that magnifies the image. A number of dots are neatly arranged to form a regularly arranged convex lens. The image is magnified by multiple lenses at different angles (left, right, up, down), and at the same time, the depth of field is generated in the viewing angle, and finally a three-dimensional effect is formed. And these patterns can be in various shapes, large or small, shading or small dots. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com