Three-dimensional printing method and decorative plate and lamp box manufactured through method

A technology of three-dimensional printing and decorative boards, which is applied to the printing of special types of printed matter, special decorative structures, and post-processing of printing, etc., which can solve the problems of long viewing distance, inaccurate registration, and lack of suitable structures for general products and methods. methods and other issues to achieve the effect of high-contrast pattern performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

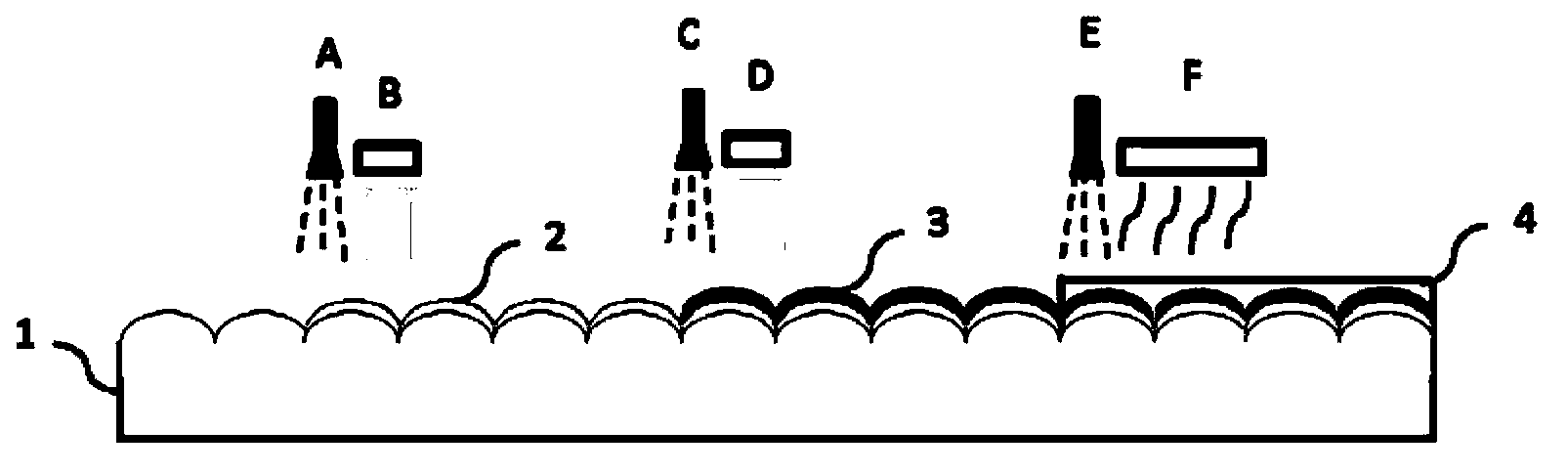

Method used

Image

Examples

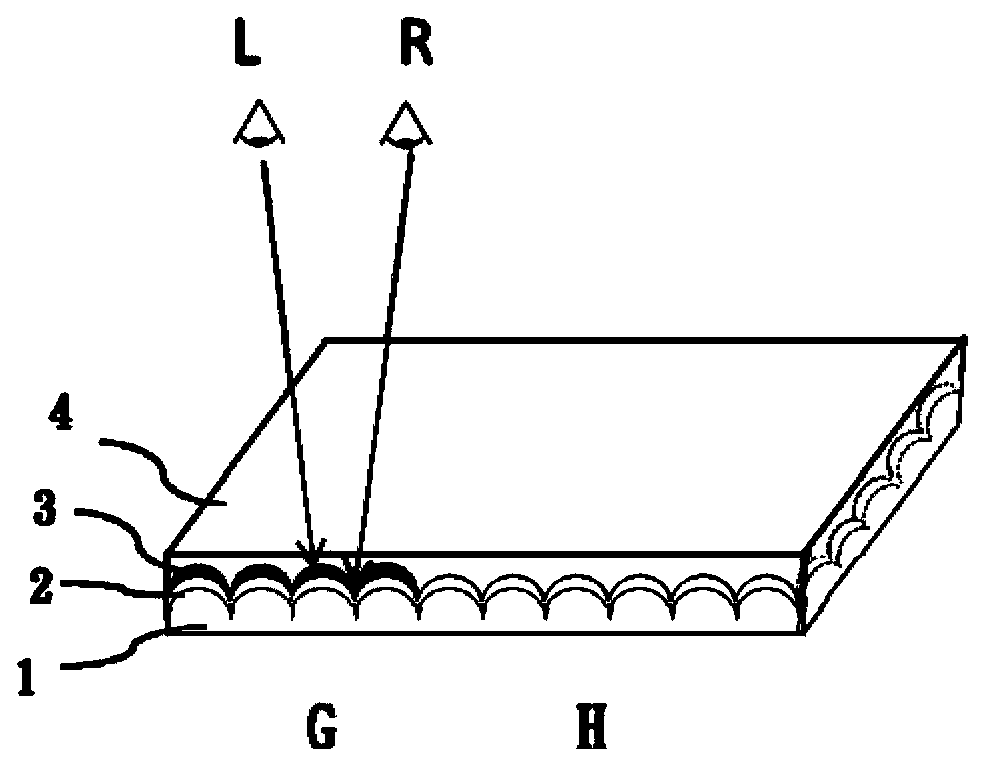

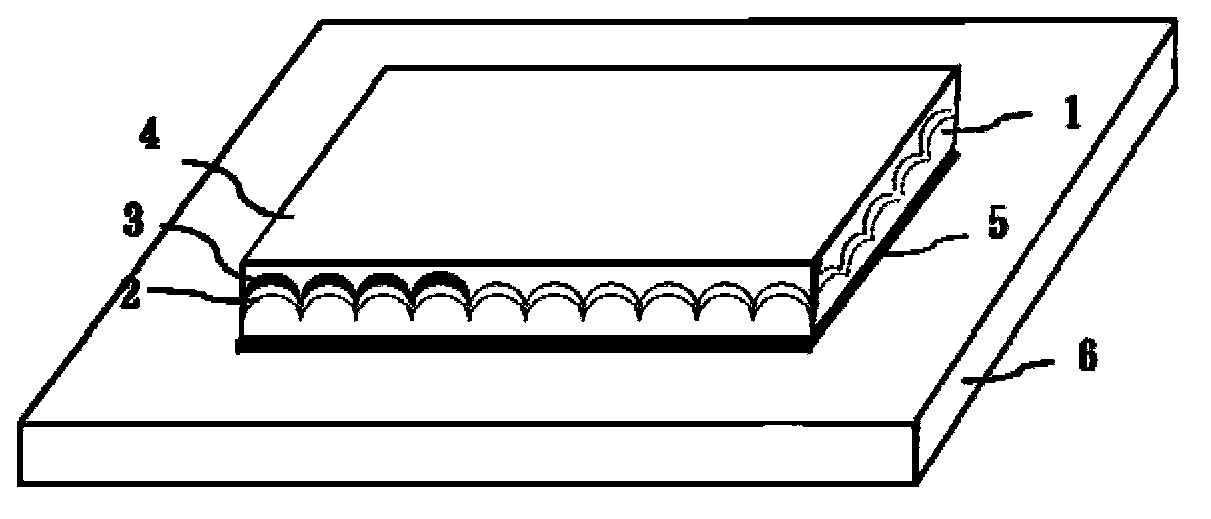

Embodiment 1

[0093] Utilize an acrylic sheet with hemispherical lenses on one side, 120 cm long and 80 cm wide, with a hemispherical lens density of 100,000 lenses per square inch. Coat the surface modifying layer 2 on it, which is to increase the adsorption and adsorption speed of the ink, and then use an industrial-grade digital inkjet printing machine exposed to ultraviolet rays to print a printing layer 3 with precise patterns. The precision of the pattern is every 1 Inch 1000 dots (equivalent to 1 million dots per square inch), then, further add a hard coating of one deck transparent resin above the pattern as ink protective layer 4, which is acrylic resin or epoxy resin, so A three-dimensional printed decorative panel is formed. The printing resolution of this example is 10 times of the lens density, and the obtained decorative board has excellent three-dimensional printing effect and pattern resolution.

[0094] Place 20 36-watt LEDs from Optoelectronics on both sides of the three-...

Embodiment 2

[0096] Utilize an acrylic sheet with hemispherical lenses, 120 cm long and 80 cm wide, with a hemispherical lens density of 40,000 lenses per square inch. Surface modifying layer 2 is coated thereon, as in the printing precision and printing process of embodiment one, the printing layer 3 of imprinting precision pattern, pattern precision is 1000 dots per inch (equivalent to 1 million dots per square inch) , Then, further add a hard coating layer of transparent resin on the top of the pattern as ink protection layer 4, which is acrylic resin or epoxy resin, thus forming a three-dimensional printed decorative plate. In this example, the printing resolution is 25 times of the lens density, and the obtained decorative board has an excellent three-dimensional printing effect, but the pattern resolution is obviously reduced.

Embodiment 3

[0098] Utilize an acrylic sheet with hemispherical lenses, 120 cm long and 80 cm wide, with a hemispherical lens density of 100,000 lenses per square inch. Surface modifying layer 2 is coated thereon, such as the printing precision and printing process of embodiment one, the printing layer 3 of imprinting precision pattern, the pattern precision is every 1 inch 500 dots (equivalent to 250,000 dots per square inch), Then, further add a layer of transparent resin hard coat on the pattern as ink protective layer 4, which is acrylic resin or epoxy resin, thus forming a three-dimensional printed decorative plate. The printing resolution of this example is 2.5 times of the lens density, and the resulting decorative plate does not have a three-dimensional printing effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brightness | aaaaa | aaaaa |

| Color temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com