A three-dimensional printing method and the decorative board and light box made therefrom

A technology of three-dimensional printing and decorative boards, which is applied to the printing of special types of printed matter, special decorative structures, and post-processing of printing, etc. It can solve the problems of long viewing distance, color difference of printed matter, uncomfortable eyes, etc., and achieve high-contrast images. The effect of striation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

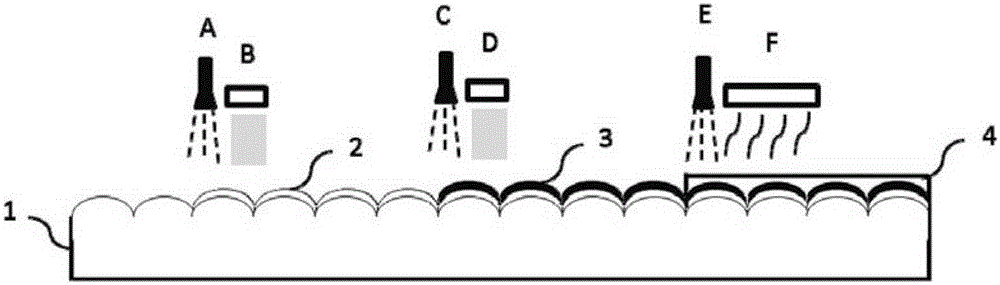

Embodiment 1

[0093] Utilize an acrylic sheet with hemispherical lenses on one side, 120 cm long and 80 cm wide, with a hemispherical lens density of 100,000 lenses per square inch. Coat the surface modifying layer 2 on it, which is to increase the adsorption and adsorption speed of the ink, and then use an industrial-grade digital inkjet printing machine exposed to ultraviolet rays to print a printing layer 3 with precise patterns. The precision of the pattern is every 1 Inch 1000 dots (equivalent to 1 million dots per square inch), then, further add a hard coating of one deck transparent resin above the pattern as ink protective layer 4, which is acrylic resin or epoxy resin, so A three-dimensional printed decorative panel is formed. The printing resolution of this example is 10 times of the lens density, and the obtained decorative board has excellent three-dimensional printing effect and pattern resolution.

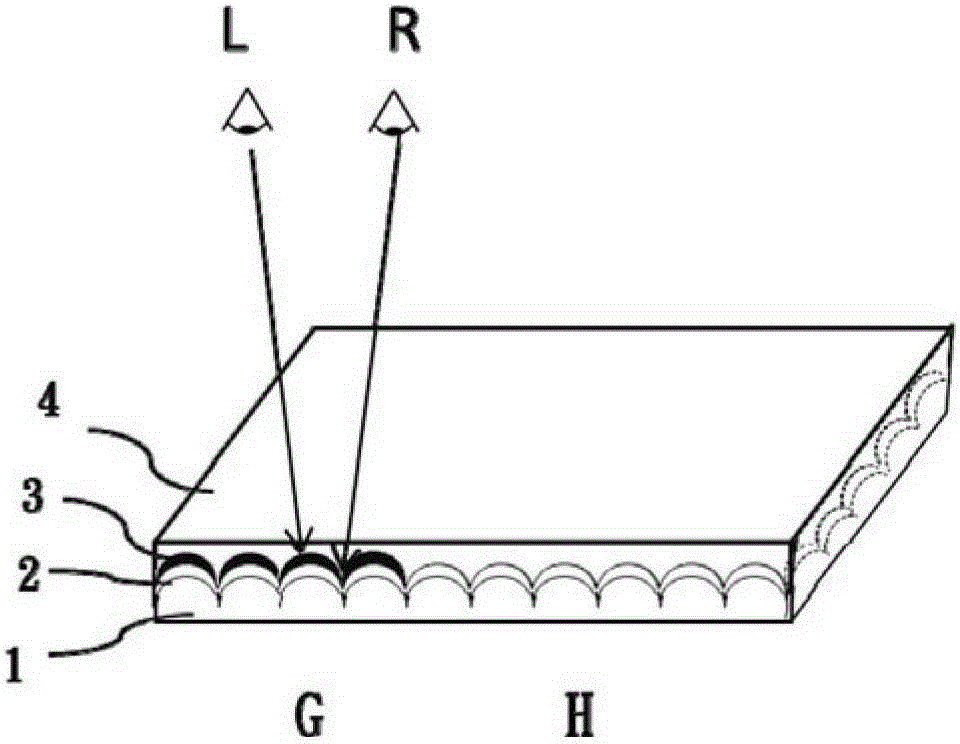

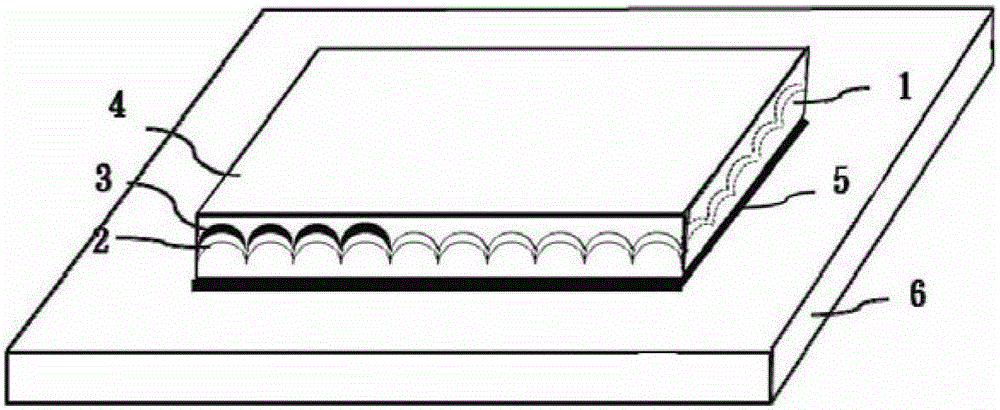

[0094] Place 20 36-watt LEDs from Optoray on both sides of the three-dimensio...

Embodiment 2

[0096] Utilize an acrylic sheet with hemispherical lenses, 120 cm long and 80 cm wide, with a hemispherical lens density of 40,000 lenses per square inch. Surface modifying layer 2 is coated thereon, as in the printing precision and printing process of embodiment one, the printing layer 3 of imprinting precision pattern, pattern precision is 1000 dots per inch (equivalent to 1 million dots per square inch) , Then, further add a hard coating layer of transparent resin on the top of the pattern as ink protection layer 4, which is acrylic resin or epoxy resin, thus forming a three-dimensional printed decorative plate. In this example, the printing resolution is 25 times of the lens density, and the obtained decorative board has an excellent three-dimensional printing effect, but the pattern resolution is obviously reduced.

Embodiment 3

[0098] Utilize an acrylic sheet with hemispherical lenses, 120 cm long and 80 cm wide, with a hemispherical lens density of 100,000 lenses per square inch. Surface modifying layer 2 is coated thereon, such as the printing precision and printing process of embodiment one, the printing layer 3 of imprinting precision pattern, the pattern precision is every 1 inch 500 dots (equivalent to 250,000 dots per square inch), Then, further add a layer of transparent resin hard coat on the pattern as ink protective layer 4, which is acrylic resin or epoxy resin, thus forming a three-dimensional printed decorative plate. The printing resolution of this example is 2.5 times of the lens density, and the resulting decorative plate does not have a three-dimensional printing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com