A kind of three-dimensional solid wood composite board with high structural strength and its forming method

A high-structure, composite board technology, used in the bonding of wooden veneers, chemical instruments and methods, wood-layered products, etc., can solve the problems of difficult to maintain a consistent state, inconvenient practical application, and the board cannot bear the load, etc. Thickness, structural stability, and the effect of improving load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

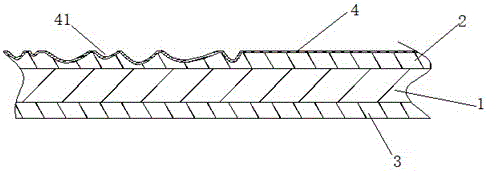

[0043] The present embodiment provides a kind of three-dimensional solid wood composite panel with high structural strength, such as figure 1 , including a hard base layer 1, and a first capacity layer group 2 and a second capacity layer group 3 arranged on both sides of the base layer; a flexible capacity layer is respectively arranged in the first capacity layer group and the second capacity layer group; It includes a surface layer 4 arranged on the surface of the first capacity layer.

[0044] In this embodiment, the above-mentioned hard base layer is a commercially available Ozon board. The flexible capacity layer is pine wood. Natural wood veneer for the finish.

[0045] Further, the thickness of the surface layer 4 is 1 mm, the thickness of the first capacity layer is 1 mm, the thickness of the second capacity layer group is 1.2 mm, and the thickness of the base layer is 25 mm.

[0046] Further, the surface layer is provided with a decorative groove 41, and the bottom...

Embodiment 2

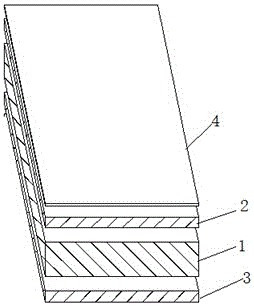

[0051] Such as figure 2 , the present embodiment provides the preparation method of embodiment 1 high structural strength three-dimensional solid wood composite board, specifically as follows:

[0052] a. Polish the Ozon board, 1, and apply glue on both sides of the Ozon board;

[0053] b. Paste a layer of pine board 2 and pine board 3 on both sides of the European pine board;

[0054] c. coating glue on the surface of one of the pine boards 2;

[0055] d. Paste one deck of natural veneer 4 on the surface of above-mentioned pine board 2;

[0056] e. Heat the above plate to 101°C under 6MP high pressure and keep it for 9 minutes;

[0057] f. Cold pressing the above plate at 5°C for 16 minutes to obtain a semi-finished plate;

[0058] g. Using a mold with embossed lines, press the semi-finished board under a pressure of 13 MP for 5 minutes to obtain the high structural strength three-dimensional solid wood composite board of this embodiment.

Embodiment 3

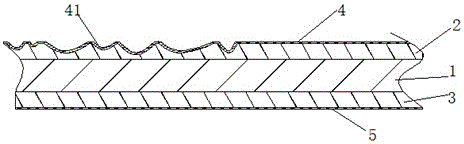

[0060] The present embodiment provides a kind of three-dimensional solid wood composite panel with high structural strength, such as image 3 , including a hard base 1, and a first capacity layer group 2 and a second capacity layer group 3 arranged on both sides of the base layer; a flexible capacity layer is respectively arranged in the first capacity layer group and the second capacity layer group; It includes a surface layer 4 arranged on the surface of the first capacity layer.

[0061] In this embodiment, the hard base layer is a reconstituted board. The capacity layer is poplar board.

[0062] Further, the thickness of the surface layer is 2 mm, the thickness of the first capacity layer is 5 mm, the thickness of the second capacity layer group is 5 mm, and the thickness of the base layer is 31 mm.

[0063] The surface layer is provided with a decorative groove 41, and the bottom of the decorative groove is embedded in the first capacity layer group.

[0064] The ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com