Brushing-shaped printing technology

A printing process and bristles technology, applied in printing, printing device, dyeing method, etc., can solve the problems of no visual effect and no hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

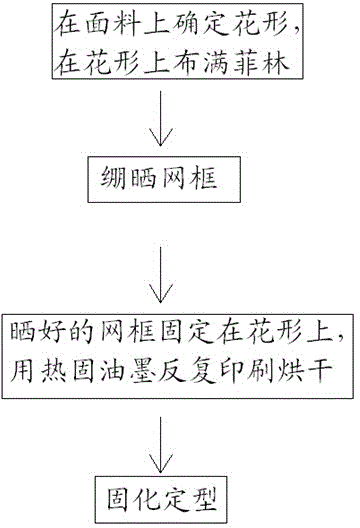

[0014] Such as figure 1 Shown, the bristle-shaped printing process comprises the following steps:

[0015] Step 1: Determine the flower shape to be printed on the surface of the fabric or fabric, and then cover the flower shape with film. The diameter of the film is 0.4mm to 0.6mm, generally 0.6mm is selected, and the spacing is 0.7mm to 1.0mm, generally 0.8mm is selected. If the diameter of the film is too thick or too thin, it will affect the visual effect. The spacing should also be strictly controlled. If the spacing is too small, the final printed bristles may stick together, which will affect the quality of the product. If the spacing is too large, the printed bristles will be too sparse, which will seriously affect the visual effect.

[0016] The second step: Stretch the screen frame. Paste the flower shape on the stretched screen frame and irradiate it with ultraviolet light. Because the film is black, where there is film, the net will be hollowed out by the sun, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com