Stock having green environment-protective three-dimensional stereo grating effect image and transfer making method

A three-dimensional, green and environmentally friendly technology, applied in the production of special varieties of printed matter in the direction of printing, printing, printed matter, etc., can solve the problems of great harm, high manufacturing cost, high cost, and achieve no pollution, reduce product costs, and reduce materials. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

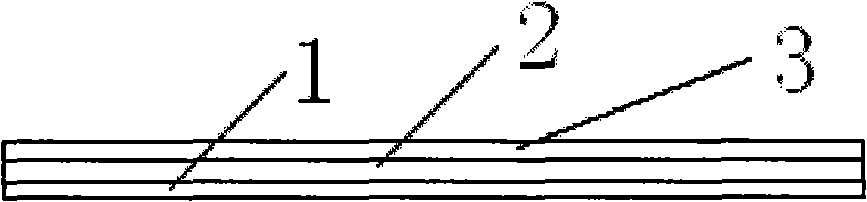

[0024] refer to figure 1 , 2 , a substrate with a green and environmentally friendly three-dimensional grating effect image, including a paper 1 with a flat printing image, a composite medium layer 2 attached to the paper 1, the composite medium layer 2 is a composite glue coating layer, and the composite glue paint layer is attached There is a grating effect layer 3 obtained by carrying out laser grating effect molding treatment on the film, peeling off the film and transferring.

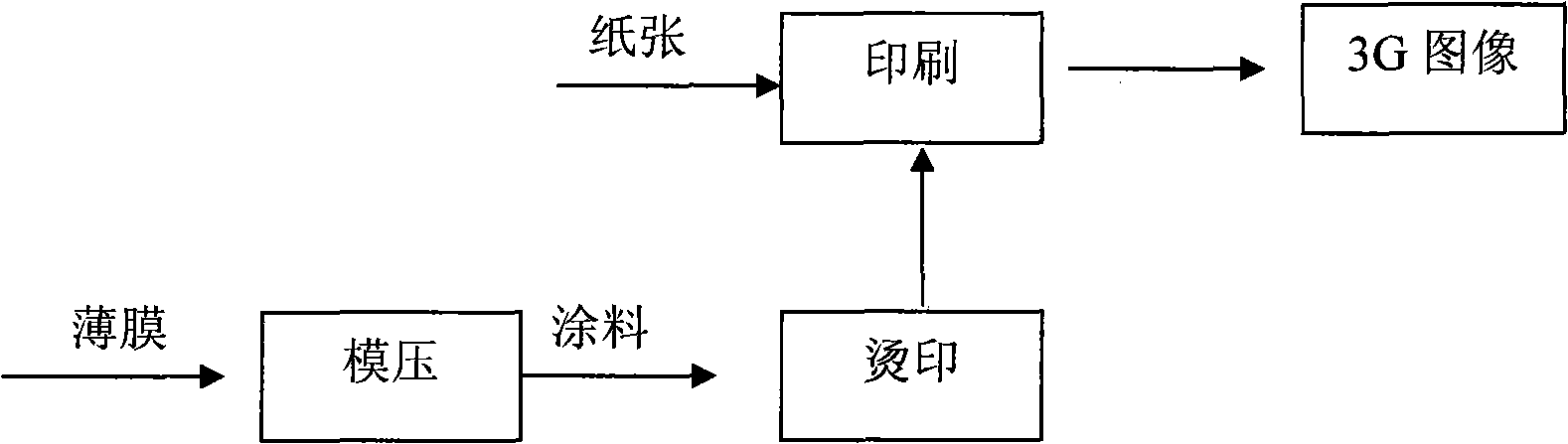

[0025] The method for transferring the above-mentioned substrate with a green and environment-friendly three-dimensional lenticular effect image includes the following steps:

[0026] 1. Design a three-dimensional picture, make and output the PS plate required for printing through software, and perform flat color printing on paper;

[0027] 2. Provide a film with an isolation layer on its surface;

[0028] 3. Carry out laser grating effect molding treatment on the above film to generate a gratin...

Embodiment 2

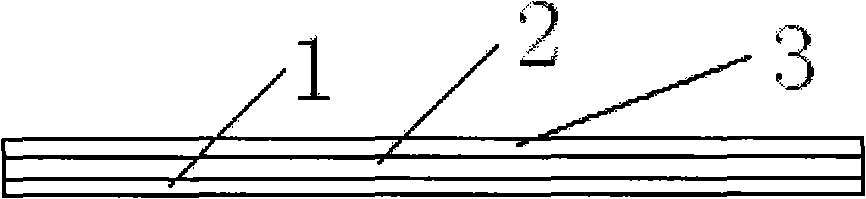

[0032] refer to image 3 , 4 , a substrate with a green and environmentally friendly three-dimensional grating effect image, including a paper 1 with a planar printing image, a composite medium layer 2 attached to the paper 1, the composite medium layer 2 is a UV varnish layer, and the UV varnish layer is attached with a The grating effect layer 3 is obtained by performing laser grating effect molding treatment on the film, peeling off the film, and then transferring.

[0033] The method for transferring the above-mentioned substrate with green and environmental protection three-dimensional lenticular effect images includes the following steps:

[0034] 1. Design a three-dimensional picture, make and output the PS plate required for printing through software, and perform flat color printing on the substrate paper;

[0035] 2. Provide a film with an isolation layer on its surface;

[0036] 3. Carry out laser grating effect molding treatment on the above film to generate a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com