Method for preparing overvoltage protection device

A protector and overvoltage technology, applied in the direction of emergency protection circuit devices, emergency protection circuit devices, electrical components, etc. for limiting overcurrent/overvoltage, which can solve the problem that the protection of electrical equipment cannot be used, and the phase and phase cannot be effectively limited. Phase overvoltage, arrester does not have arc suppression function, etc., to achieve the effect of protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: (1) Dry the zinc oxide resistor, the drying temperature is 80°C, and the drying time is 10 hours;

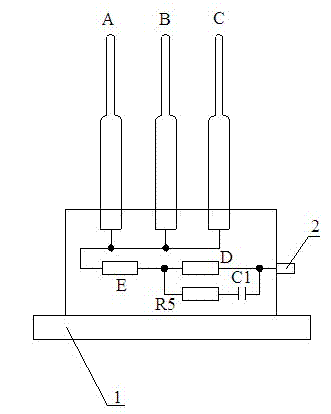

[0025] (2) Configure the first resistance piece A, the second resistance piece B, the third resistance piece C and the discharge device: use a dried zinc oxide resistance piece of 42x17kV and two aluminum electrodes of 42x30kV in series Form the first resistance piece A, and use the impregnated glass fiber silk without latitude tape to wind and shape, wherein the zinc oxide resistance piece of 42x17kV is connected in series between two aluminum electrodes of 42x30kV; the second resistance piece B and the first The configuration process of the three resistors C is exactly the same as that of the first resistor A; use a 9.1kV zinc oxide resistor in series with a 11.3kV discharge gap, and connect the fifth resistor R5 in parallel at both ends of the discharge gap A series circuit formed with capacitor C1 is configured as a discharge device;

[0026] (3) Dry ...

Embodiment 2

[0031] Embodiment 2: (1) Dry the zinc oxide resistor, the drying temperature is 100°C, and the drying time is 9 hours;

[0032] (2) Configure the first resistor A, the second resistor B, the third resistor C and the discharge device: use one dried ? 42x17kV zinc oxide resistor in series with two ? 42x30kV aluminum electrodes. The first resistor sheet A is wound with rubber-impregnated glass fiber latitude-free tape, wherein the ?42x17kV zinc oxide resistor sheet is connected in series between two ?42x30kV aluminum electrodes; the second resistor sheet B and the third The configuration process of resistor C is exactly the same as that of the first resistor A; use a 9.1kV zinc oxide resistor in series with a 11.4kV discharge gap, and connect the fifth resistor R5 and The series circuit formed by the capacitor C1 is configured as a discharge device;

[0033] (3) Dry and shape the configured first resistor A, second resistor B, third resistor C and the discharge device. The dry...

Embodiment 3

[0038] Embodiment 3: (1) Dry the zinc oxide resistor, the drying temperature is 120°C, and the drying time is 8 hours;

[0039](2) Configure the first resistor A, the second resistor B, the third resistor C and the discharge device: use one dried ? 42x17kV zinc oxide resistor in series with two ? 42x30kV aluminum electrodes. The first resistor sheet A is wound with rubber-impregnated glass fiber latitude-free tape, wherein the ?42x17kV zinc oxide resistor sheet is connected in series between two ?42x30kV aluminum electrodes; the second resistor sheet B and the third The configuration process of resistor C is exactly the same as that of the first resistor A; use a 9.1kV zinc oxide resistor in series with a 11.5kV discharge gap, and connect the fifth resistor R5 and A series circuit composed of capacitor C1 is configured with a discharge device;

[0040] (3) Dry and shape the configured first resistor A, second resistor B, third resistor C and the discharge device. The drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com