Automatic incubator and working process thereof

An automatic, box-shaped technology, applied in the field of hatching eggs, can solve the problem of difficult temperature control, achieve basic temperature balance, local temperature control is convenient and accurate, and solve the effect of difficult temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

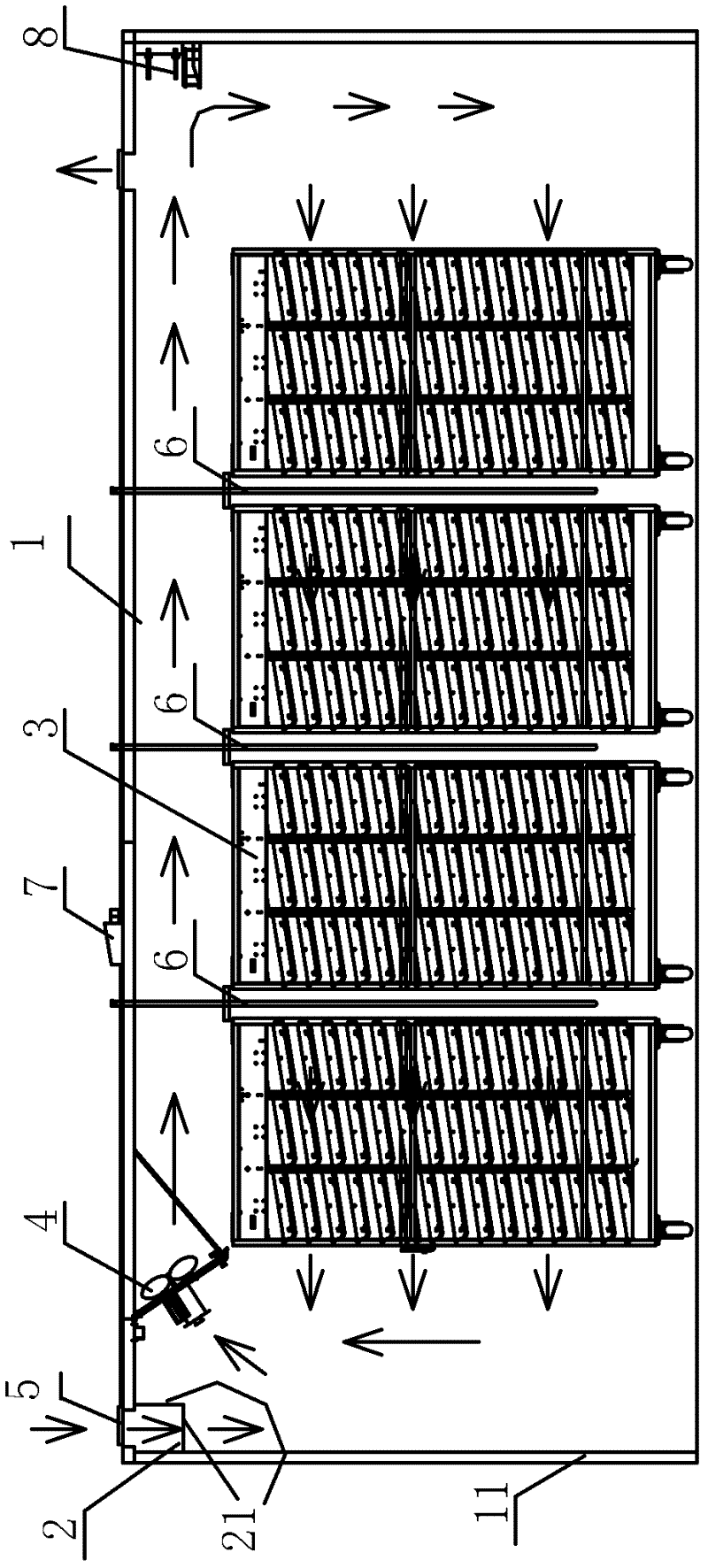

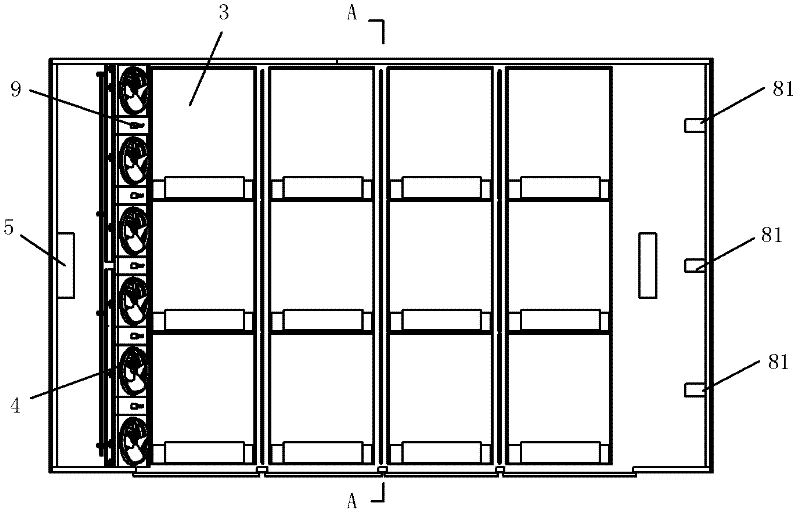

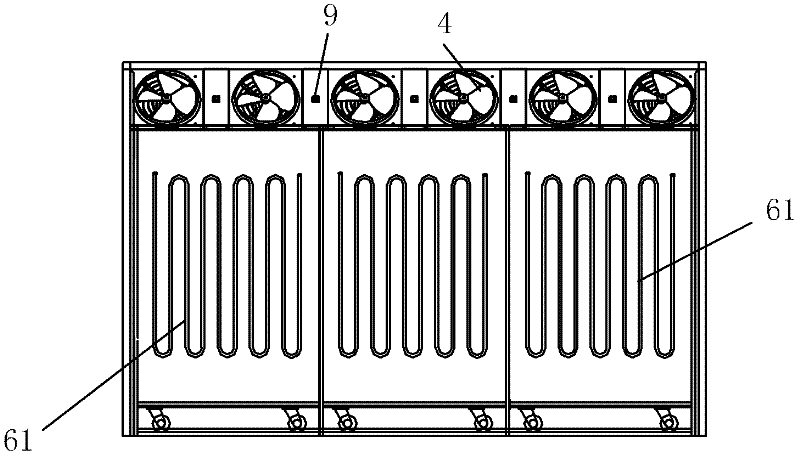

[0022] see figure 1 Shown: a kind of automatic incubator provided by the present invention, comprises: box body 1 and the processor (not shown in the figure) that is located on box body 1, balance air inlet pipe 2, egg rack trolley 3, go to egg rack Vehicle forced air supply fan 4, air inlet 5, heat exchange coil 6, measuring CO in the incubator box 2 Concentration of CO 2 Sensor (not shown in the figure), damper 7 and temperature sensor 8, CO 2 The sensor is set in the box body 1, the damper 7 is set in the middle of the top plate of the box body 1, and the processor is respectively connected with the CO 2 The sensor is connected with the air door 7, and the CO2 concentration exceeds the set value, and the processor controls the opening of the air door 7 through a relay. The processor converts the CO of different days of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com