Printer and method for driving the same

A technology for printers and printing media, used in typewriters, printing devices, printing, etc., can solve the problems of label printers unable to correctly transmit linerless labels, increased viscosity of linerless labels, and deterioration of printing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

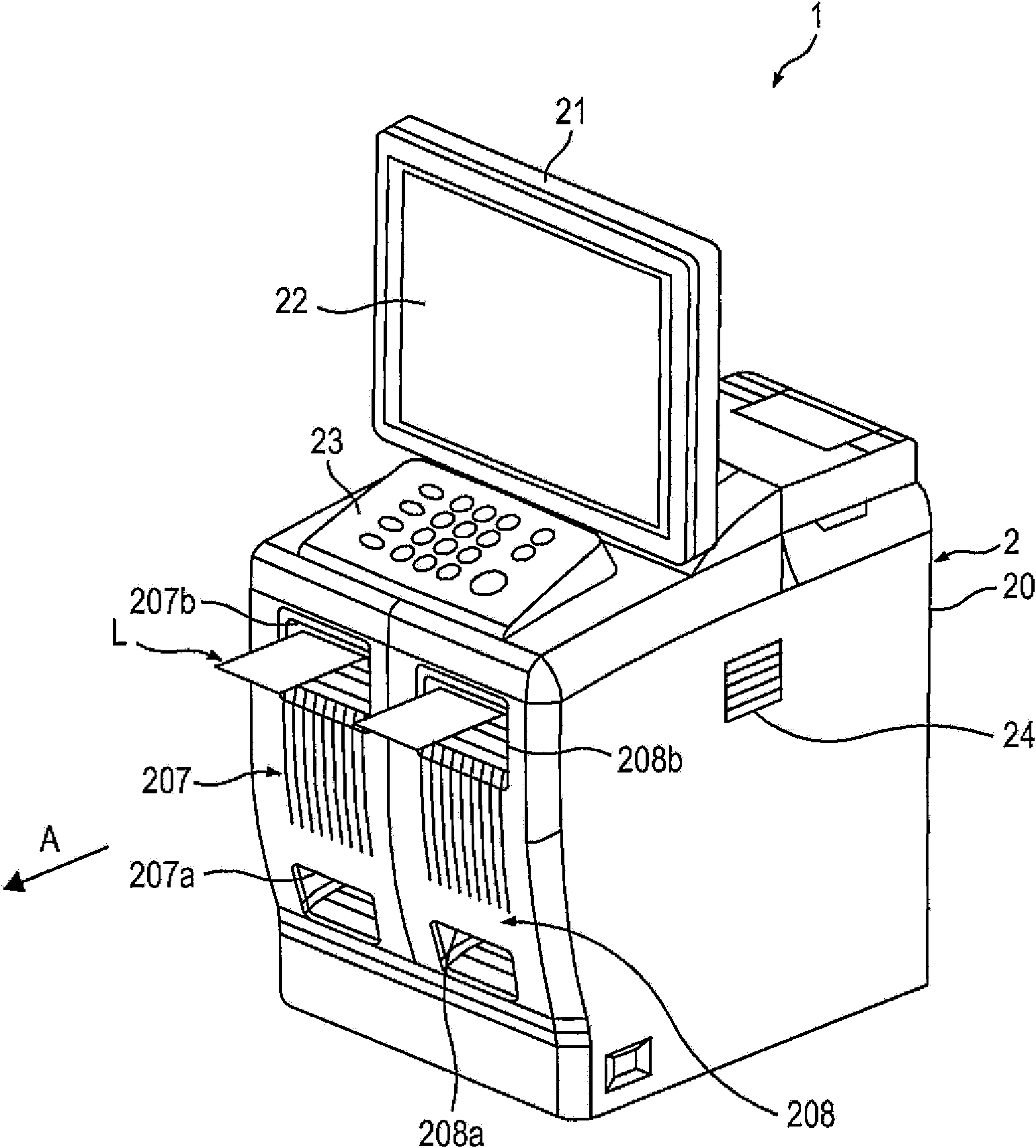

[0021] A printer according to one embodiment described below is a label printer that can be installed in a store backyard or elsewhere and used to print labels with information on commodities such as food.

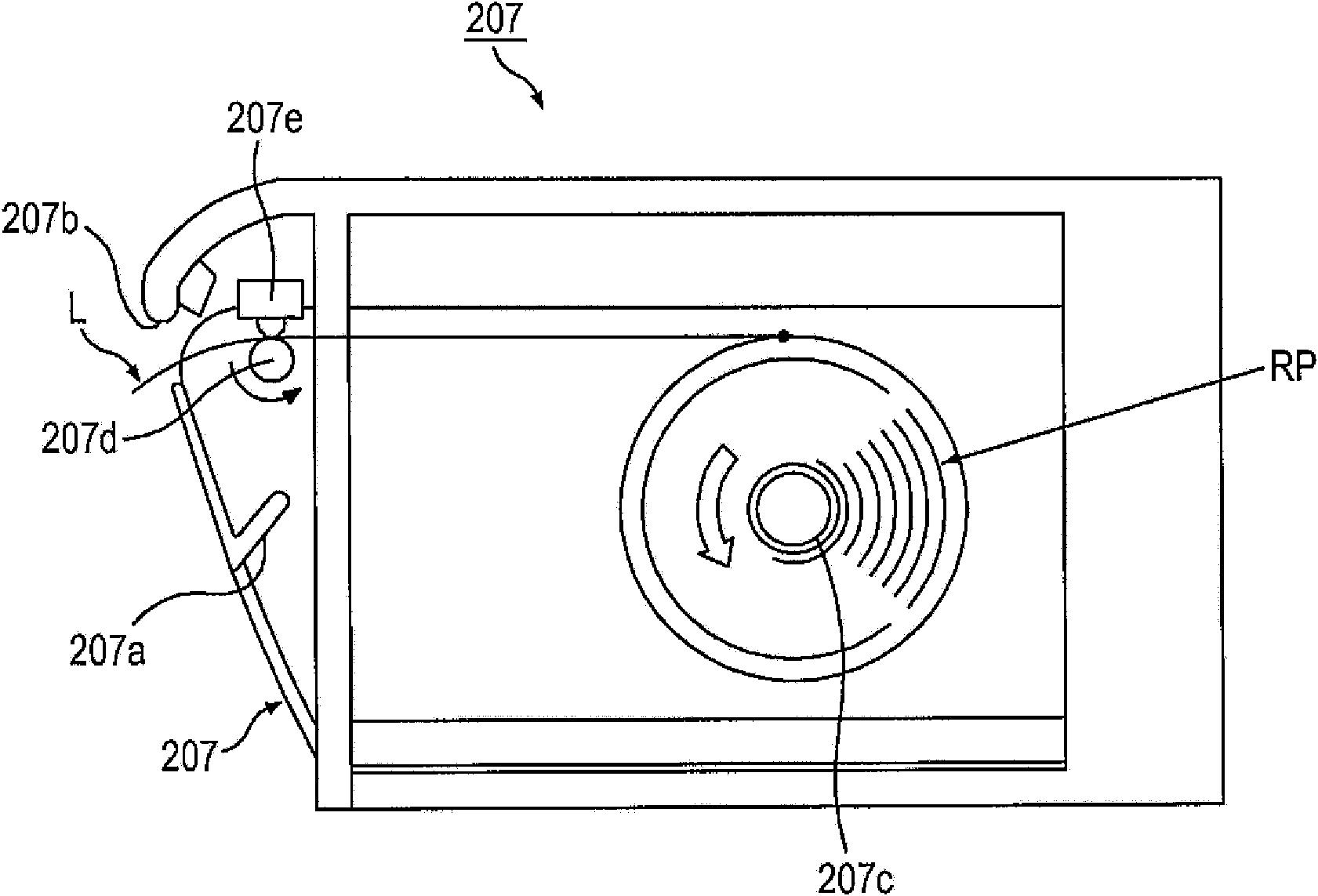

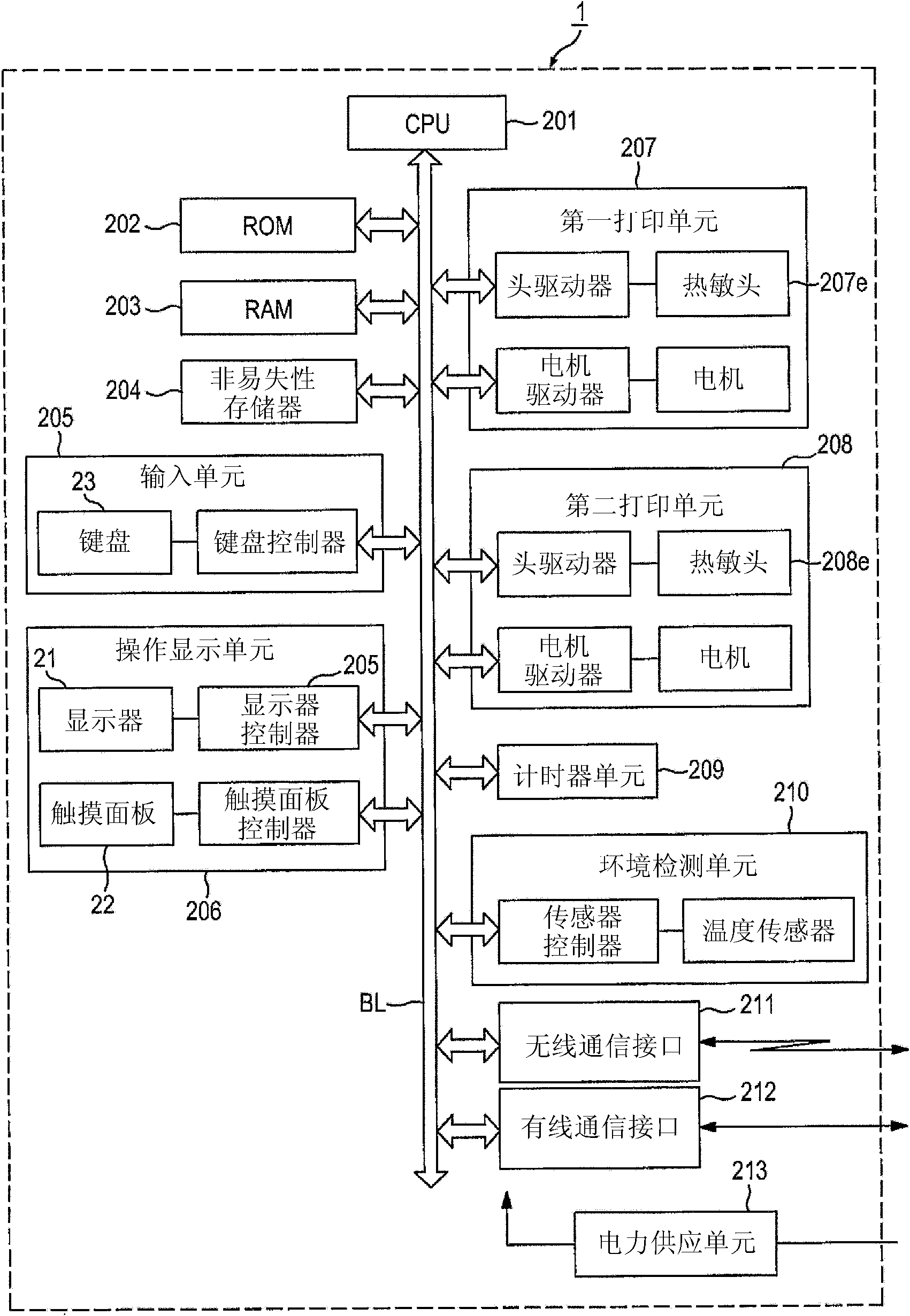

[0022] figure 1 is a perspective view of a label printer according to one embodiment. figure 2 is shown figure 1 The schematic structure of the printing unit in the label printer and the side view of the conveying state of the linerless label in this label printer are shown in .

[0023] Such as figure 1 As shown in , a label printer 1 includes a printing device 2 for printing a linerless label L having information such as a product name, price, weight, barcode, etc. on a product. The printing device 2 can be electrically connected to a weighing instrument (not shown).

[0024] On the upper surface of the body case 20, the printing device 2 includes: a display 21 for displaying information to be printed on the linerless label L; a touch panel 22 laminated on the displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com