X-Y axial fine turning device for test bench of engine

A technology of fine-tuning device and test bench, which is applied in the direction of engine test, measurement device, machine/structural component test, etc., to achieve the effect of convenient operation, improved accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

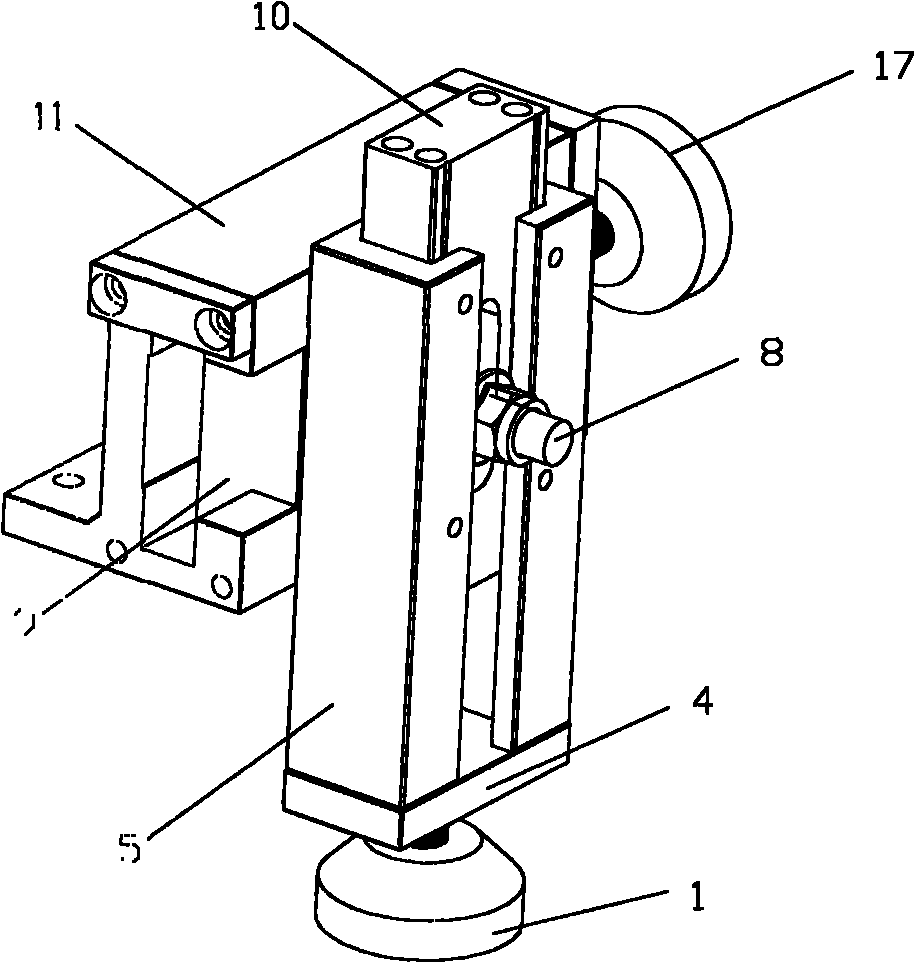

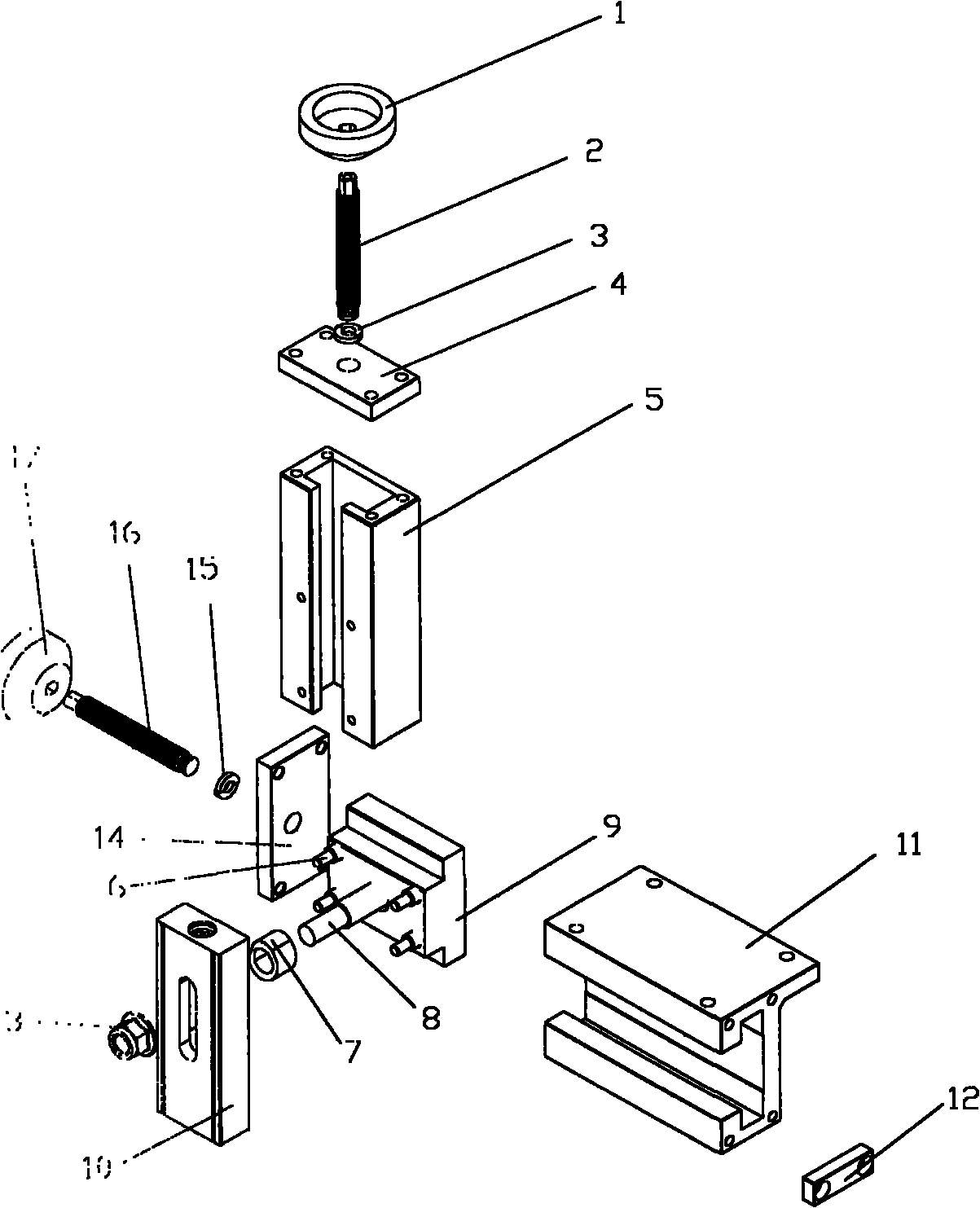

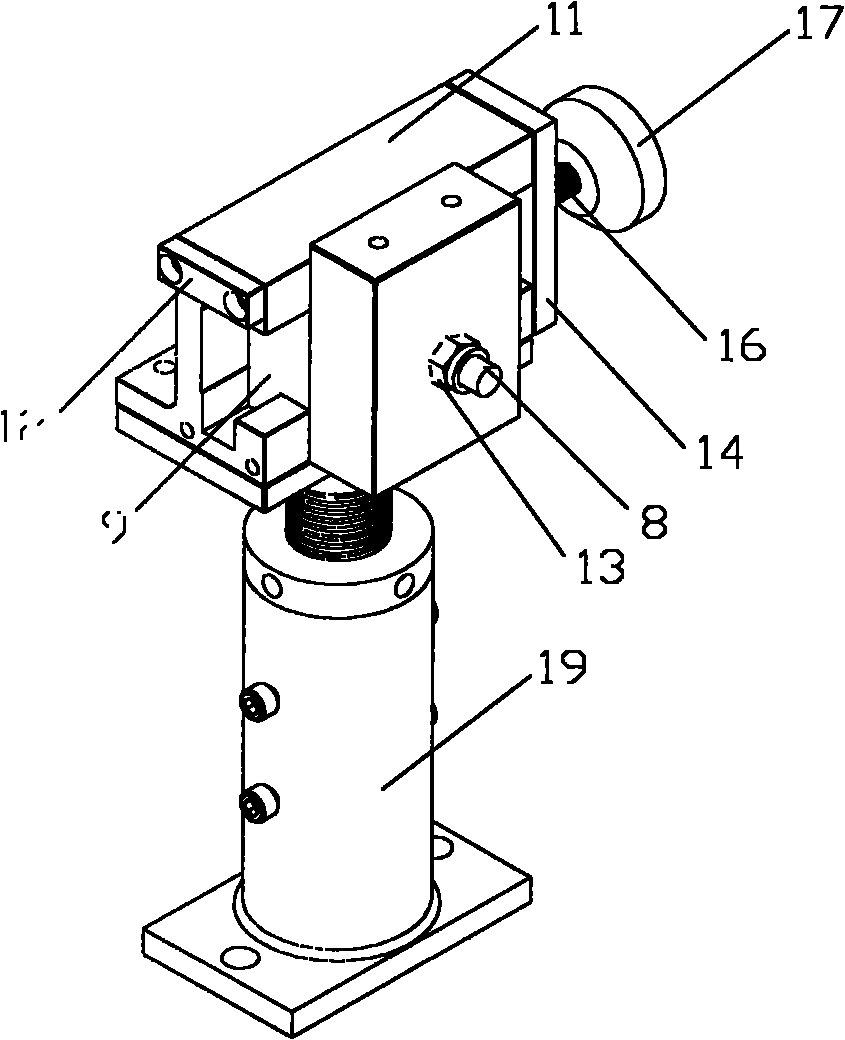

[0020] Below in conjunction with accompanying drawing, the present invention will be further described, figure 1 , 2 Among them, the X-Y axial fine-tuning device of the engine test bench is characterized in that it is composed of an X-axis fine-tuning device and a Y-axis fine-tuning device connected vertically to each other, and the X-axis fine-tuning device includes: an X-axis sliding Block 9, X-axis guide rail 11, X-axis nut support plate 14, X-axis adjustment screw 16 and X-axis adjustment handle 17, and X-axis slider 9 is provided with multiple locking pins 6 and fixing screws 8 ; The X-axis slide block 9 is installed in the X-axis guide rail 11, the X-axis nut support plate 14 is connected with the front end surface of the X-axis guide rail 11 by bolts, and the X-axis adjustment handle 17 passes the X-axis adjustment screw rod 16 and the X-axis The threaded through hole to the support plate 14 is fixedly connected with the X-axis sliding block 9 .

[0021] The Y-axis fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com