Wiper blade having an adapter unit for attaching to a wiper arm

A transfer unit and wiper blade technology, which is applied to vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of complexity, time-consuming wiper blade assembly, and difficulty in manually operating the transfer unit, and achieves a simple structure, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

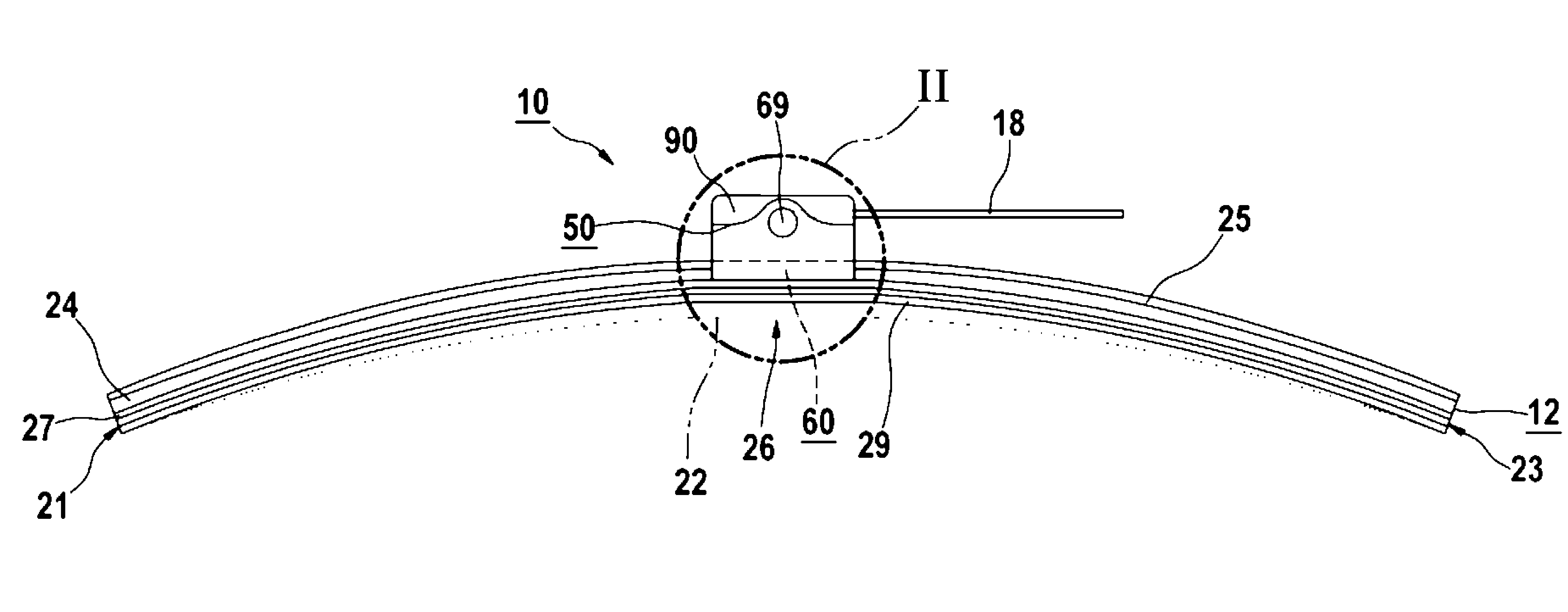

[0028] According to one embodiment, the wiper blade 10 is designed as a flat beam, ie the wiper strip 12 has a lateral longitudinal groove in which two bearings are arranged. Guide rails, preferably spring guide rails. Alternatively, the wiper strip 12 can be designed as a hollow profile with an approximately central longitudinal channel in which a separate support rail is arranged. The wiper strip 12 and the base connecting device 60 arranged thereon are preferably configured in a hingeless manner, wherein the base connecting device 60 is preferably preassembled on the wiper strip 12 .

[0029] exist figure 1 The wiper blade 10 is not completely placed on the glass 22, only its axial wiper blade ends 21, 23 are close to the glass 22, and the wiper slat 12 is in the middle of the wiper blade 26 , that is to say approximately in the region of the adapter unit 50 is still at a distance from the glass 22 . The wiper strip 12 bears against the windshield 22 when a predetermined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com