Branching, peeling and trimming integrated device

A wire-splitting and wire-cutting technology, applied in circuit/collector parts, electrical components, circuits, etc., can solve the problems of low production efficiency and waste, and achieve the effect of improving production efficiency and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

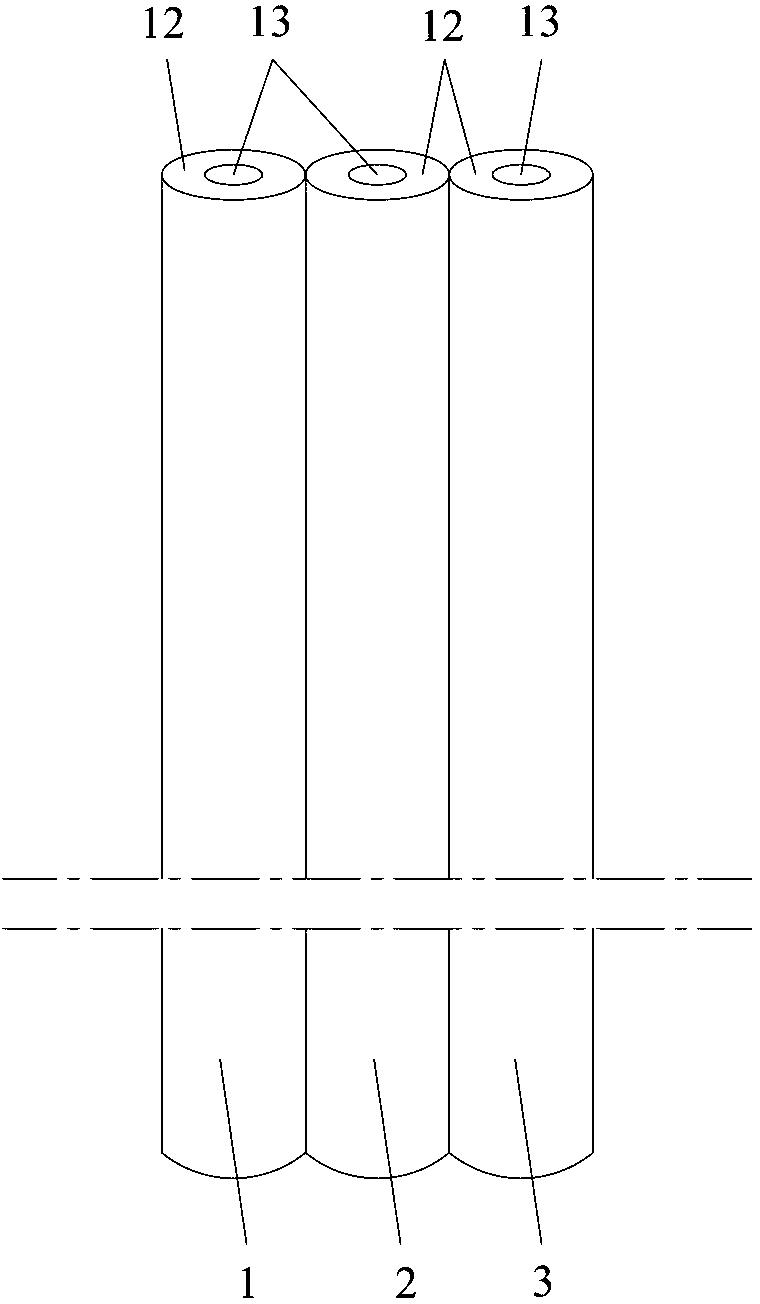

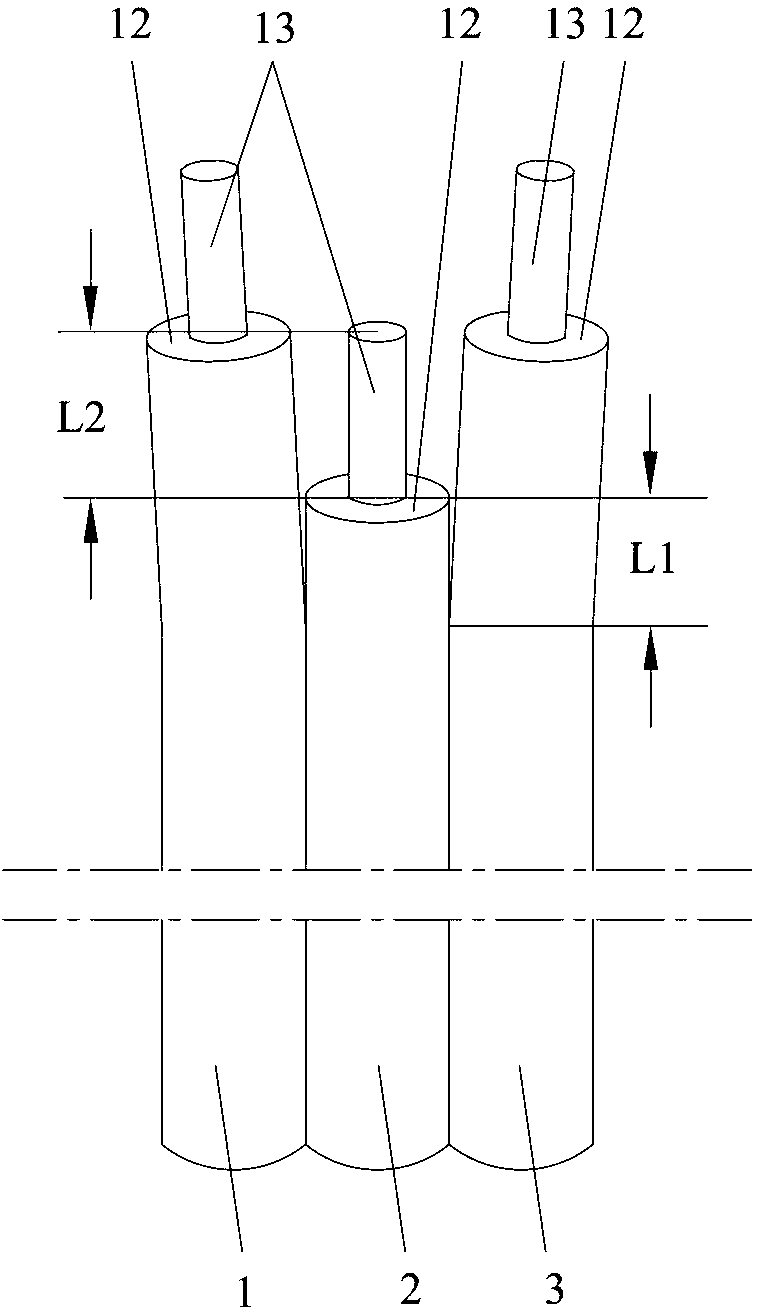

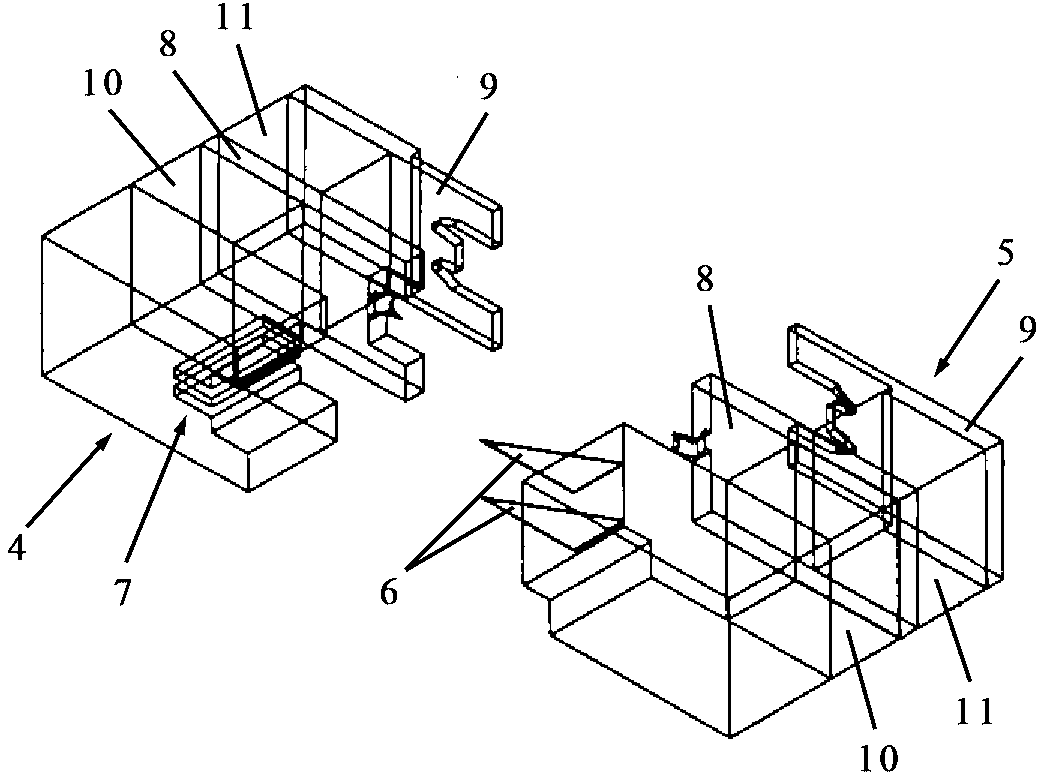

[0018] Embodiment one: see attached figure 1 to attach image 3 shown.

[0019] An integrated wire splitting, stripping and trimming device is installed on a stripping machine to realize the splitting, stripping, and trimming operations of live wire 1, ground wire 2, and neutral wire 3 arranged side by side.

[0020] The integrated wire splitting, stripping and trimming device includes a first part 4 and a second part 5, and the first part 4 and the second part 5 are respectively provided with a splitting mechanism, a ground wire stripping mechanism, and a stripping and trimming mechanism;

[0021] The line dividing mechanism includes two parallel line dividing blades 6 arranged on the first part 4 in the horizontal direction, and a groove 7 matched with the line dividing blades 6 arranged on the second part 5;

[0022] The ground wire stripping mechanism includes a pair of ground wire stripping blades 8 respectively arranged on the first part 4 and the second part 5;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com