Large-size low-temperature destructive distillation system for low-order lignite

A dry distillation and lignite technology, applied in the field of dry distillation, can solve problems such as waste of resources, lower heat utilization efficiency, uneven semi-coke quality, etc., and achieve the effects of eliminating hidden dangers of clogging, improving energy utilization, and avoiding secondary pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

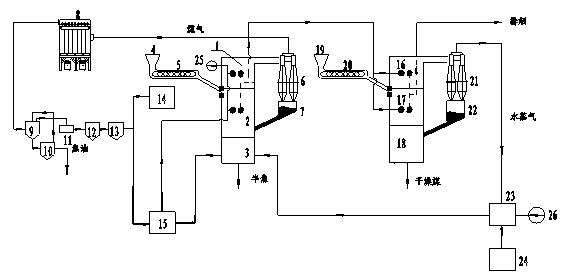

[0019] The low-rank lignite large-scale low-temperature carbonization system of the present invention is composed of a coal preparation part, a drying part, a carbonization part, a heat source part, a semi-coke cooling and conveying part, and a gas tar processing part, which are combined below figure 1 The present invention is further described.

[0020] Coal preparation part: the crushed raw coal has a particle size of 30mm-50mm and is sent to the top coal bunker 19 of the drying tower, and then sent to the tubular drying tower 17 by the raw coal screw feeder 20.

[0021] Drying part: The drying part includes the second tube group filter box 16, the tube drying tower 17, the coal storage bunker 18, the second cyclone separator 21, and the second gravity dust collector 22. Wherein the filter box of the second tube group is located at the upper part of the tubular drying tower and communicated with it, and the tubular drying tower is located at the upper part of the coal storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com