Air spring with stiffness adjusted by filler and pressure and step-pressure buffer

An air spring, pressure technology, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problem of non-continuous adjustment of stiffness, achieve smooth and continuous adjustment, reasonable and controllable adjustment stiffness characteristic curve, Effects of unresponsive time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

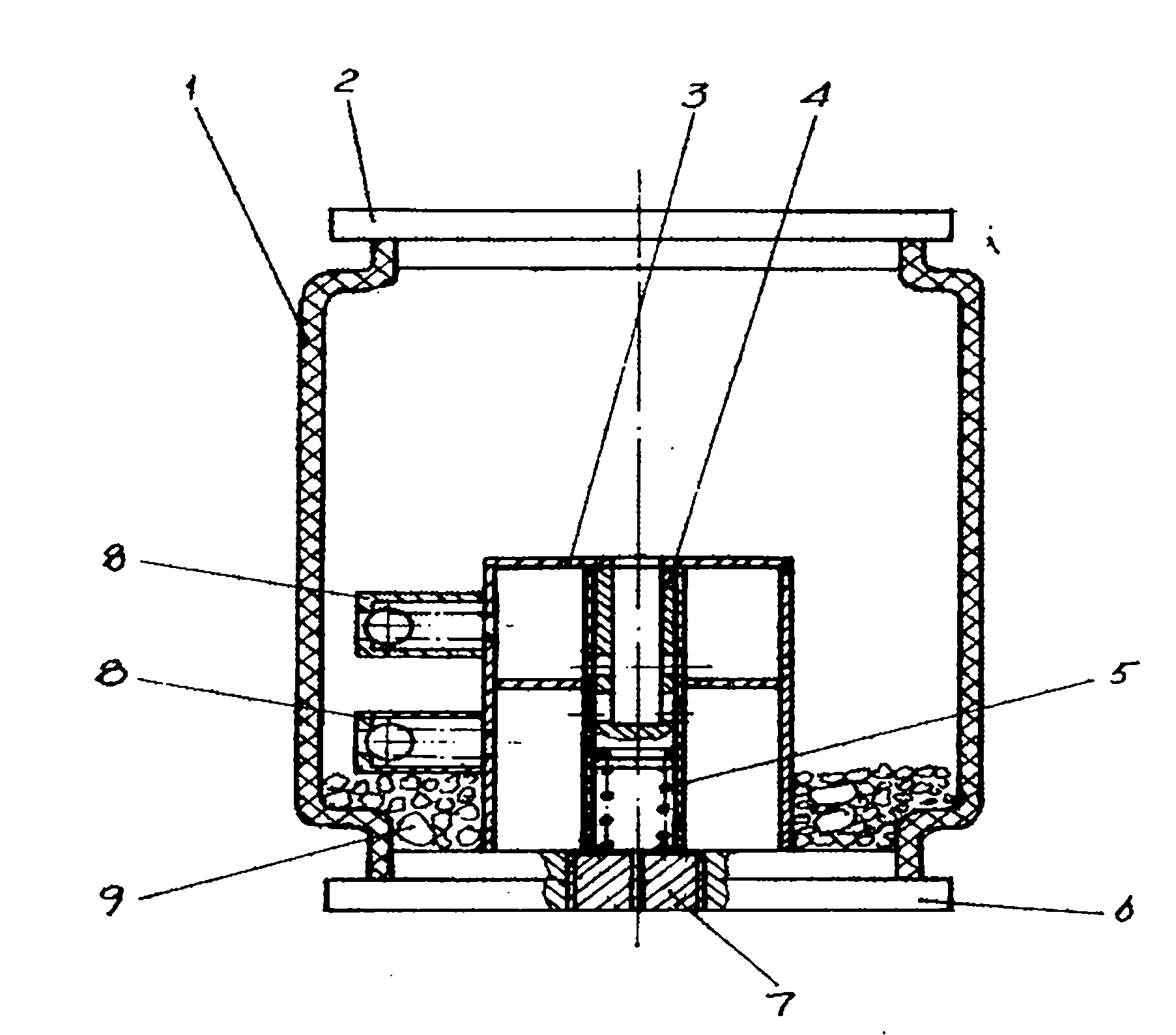

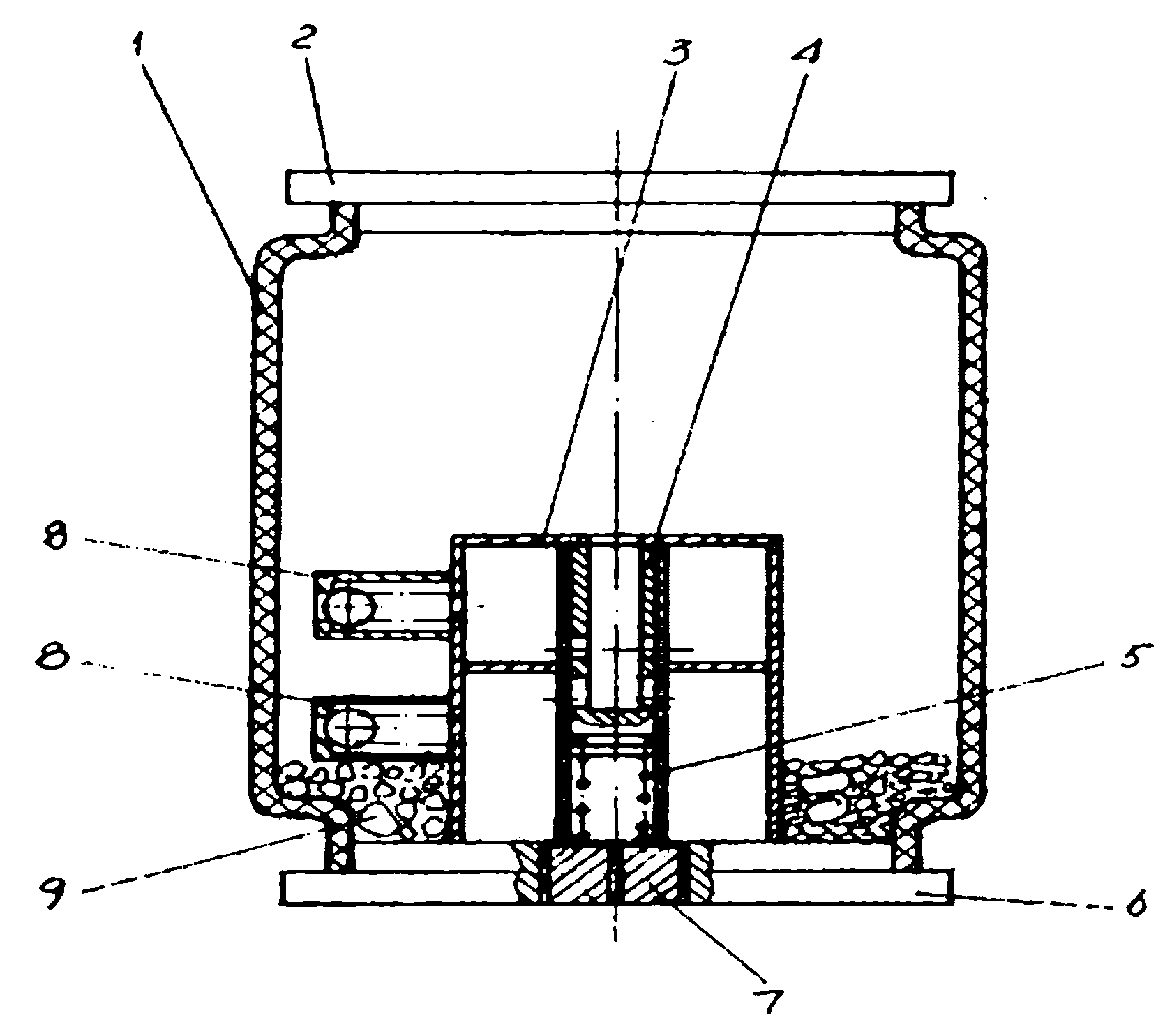

[0008] The specific embodiment of the present invention is: the static stiffness adjustment of the air spring: when the air spring is assembled, before the upper mounting plate 2 is installed, fill the airbag 1 with a filler 9 whose volume is determined by calculation, and the filled filler 9 occupies The volume in the airbag 1 is reduced, the effective volume of the gas in the airbag 1 is reduced, and the static stiffness of the air spring is improved; on the contrary, the part of the filler 9 that has been filled is taken out from the upper mounting plate 2, and the air spring is reduced. Static stiffness; dynamic stiffness adjustment of the air spring: the air pressure in the airbag 1 acts directly on the upper end surface of the throttle valve core 4, and its lower end is axially supported by the spring 5. When the vehicle is at no-load and at a set height, the air spring airbag The thrust generated by multiplying the air pressure in 1 by the cross-sectional area of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com