Coiling method for preventing hot rolling strip steel from being flatly coiled

A technology of hot-rolled strip steel and flat coil, which is applied in the field of hot-rolled strip steel coiling, can solve problems such as flat coil, achieve no additional cost, be easy to implement, and improve the effect of flat coil problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] High-strength weathering steel, the thickness of the strip steel is from 2mm to 4mm, the weight percentage of the chemical composition of the strip steel is shown in Table 1, and the remainder is Fe and unavoidable impurities.

[0029]Table 1: The weight percentage table (unit: %) of the chemical composition of steel strip

[0030] C

Si

mn

P

S

N

Mo

Ti

Cr

Cu

Nb

0.146

0.48

1.50

0.011

0.0037

0.0053

0.2

0.04

0.98

0.49

0.15

[0031] According to the coiling method of the present invention, the coiling temperature is controlled at 550±10° C., the cooling rate is to decrease by 30° C. per second, and stay for 0, 20, 30, 40 and 60 seconds respectively after coiling.

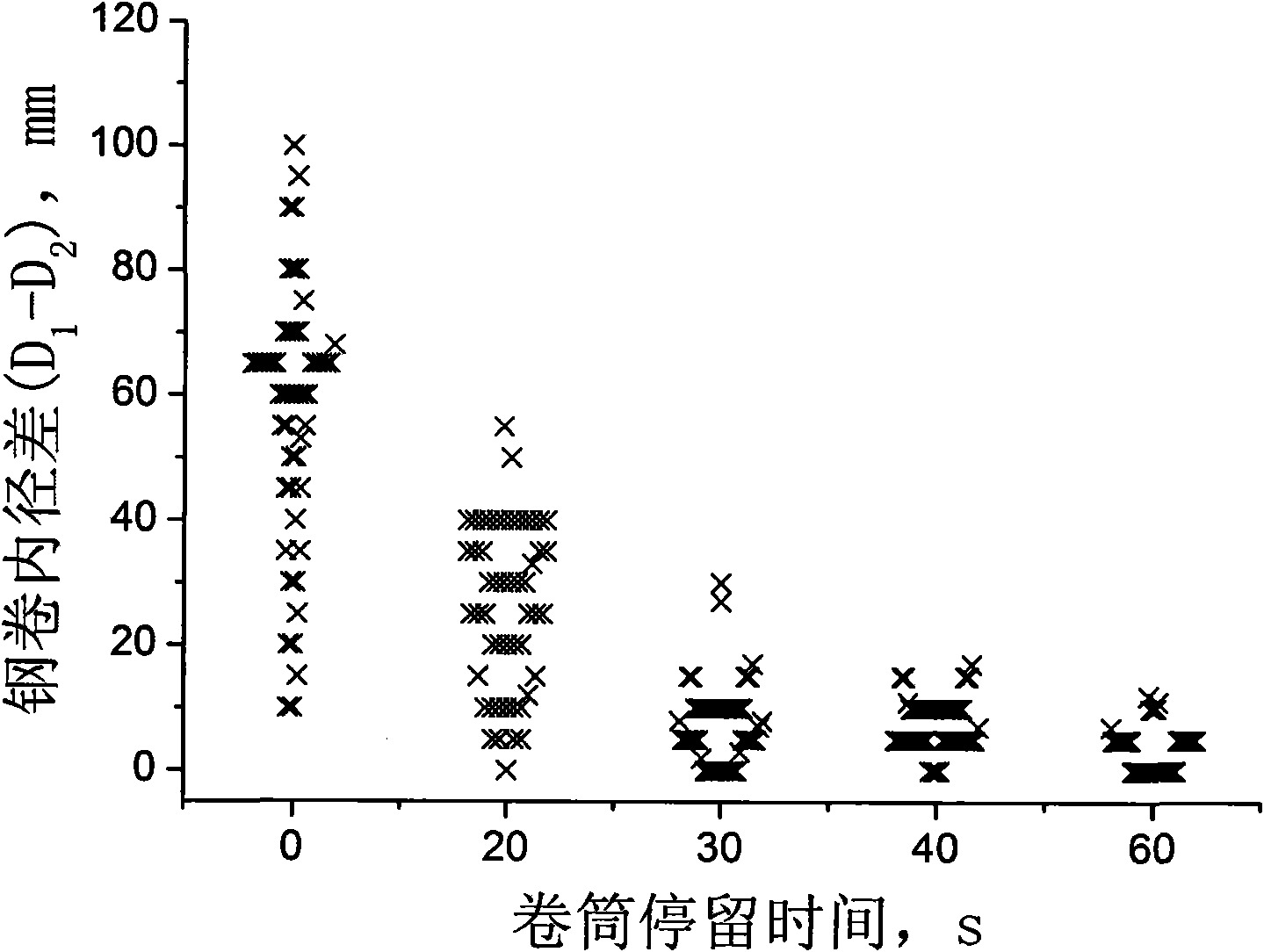

[0032] figure 2 It is the statistical result of the steel coil flat coil degree and the reel residence time relation that embodiment 1 coiling method coils, as figure 2 As show...

Embodiment 2

[0036] High-strength and high-manganese steel, strip thickness 2.82mm ~ 3.02mm, the weight percentage of the chemical composition of the strip is shown in Table 2, the remainder is Fe and unavoidable impurities.

[0037] Table 2: The weight percentage table (unit: %) of the chemical composition of strip steel

[0038] C

Si

mn

P

S

N

Ti

Cr

Mo

Nb

0.98

1.46

2.97

0.009

0.002

0.0046

0.15

0.2

0.8

0.09

[0039] According to the coiling method of the present invention, the coiling temperature is controlled at 590±10° C., the cooling rate is to drop 20° C. per second, and stay for 50 seconds after coiling.

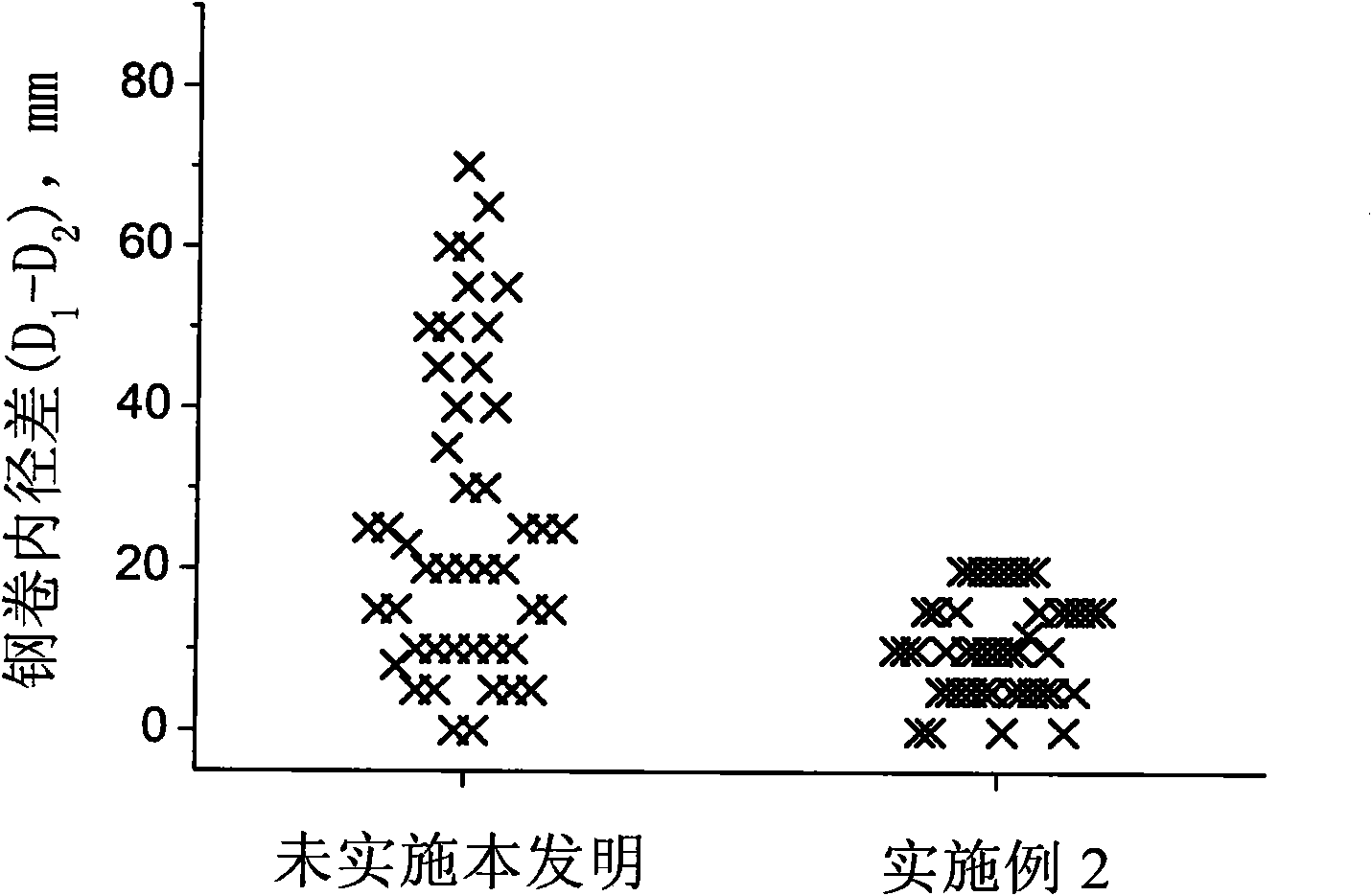

[0040] image 3 It is the statistical result of the flat coil degree of the strip steel coil in embodiment 2 and the flat coil degree of the strip steel coil not implementing the present invention. Such as image 3 As shown, there are 45 volumes of steel co...

Embodiment 3

[0042] High-strength cold-rolled martensitic steel hot-rolled coils, strip thickness 2.82mm, the weight percentage of the chemical composition of the strip is shown in Table 3, and the remainder is Fe and unavoidable impurities.

[0043] Table 3: The weight percentage table (unit: %) of the chemical composition of steel strip

[0044] C

Si

mn

P

S

N

Ti

0.132

0.36

1.03

0.011

0.0059

0.0029

0.05

[0045] According to the coiling method of the present invention, the coiling temperature is controlled at 510±10° C., the cooling rate is to decrease by 40° C. per second, and stay for 30 seconds after coiling.

[0046] Figure 4 It is the statistical result of the strip steel coil flat coil degree of embodiment 3 and the strip steel coil flat coil degree not implementing the present invention, as Figure 4 As shown, there are 40 coils without implementing the present invention, of which 35 coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com