Liquid level control system

A technology of liquid level control and liquid level relay, applied in liquid level control, control/regulation system, non-electric variable control and other directions, can solve the problems of inconvenient installation, debugging and maintenance, liquid level stay, etc. The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

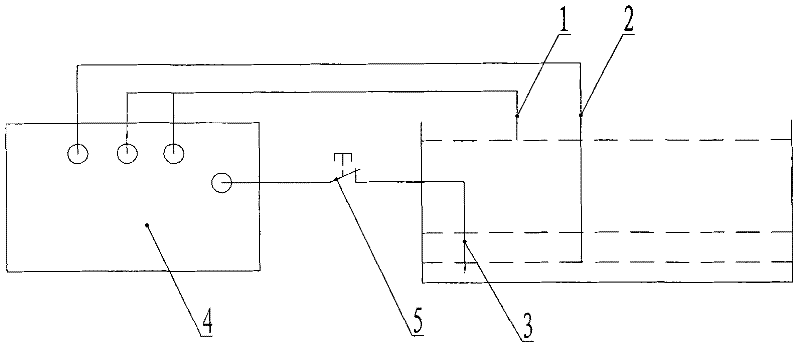

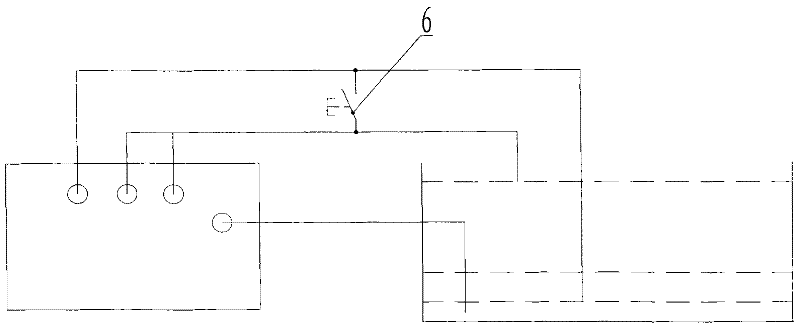

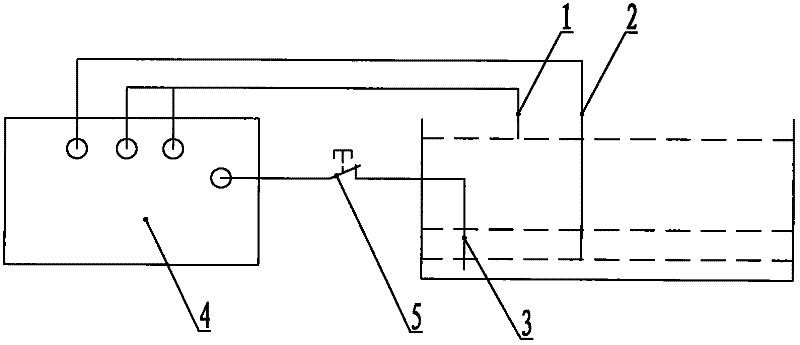

[0013] Such as Figure 1~2 As shown, the liquid level control system of the present invention includes an upper limit probe 1, a lower limit probe 2, an auxiliary probe 3, a liquid level relay 4, an AC contactor and a pump, and the upper limit probe 1, the lower limit probe 2, the auxiliary probe 3 and the AC The contactors are respectively connected to the corresponding contacts of the liquid level relay 4 through wires, the pump is connected to the AC contactor through wires, and a switch is also included, and the switch is connected to the connection between the auxiliary probe 3 and the liquid level relay 4. On the wire, or connected between the wires connected between the upper limit probe 1 and the lower limit probe 2 and the liquid level relay 4 respectively.

[0014] Preferably, the switch connected to the wire connecting the auxiliary probe 3 and the liquid level relay 4 is a normally closed button switch 5 .

[0015] Preferably, the switch connected between the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com