Solid garbage crusher

A solid waste and crusher technology, applied in the direction of grain processing, etc., can solve the problems of blockage and shutdown of the crusher, affecting the work progress, and high labor intensity, so as to avoid forced crushing, improve service life, and improve crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

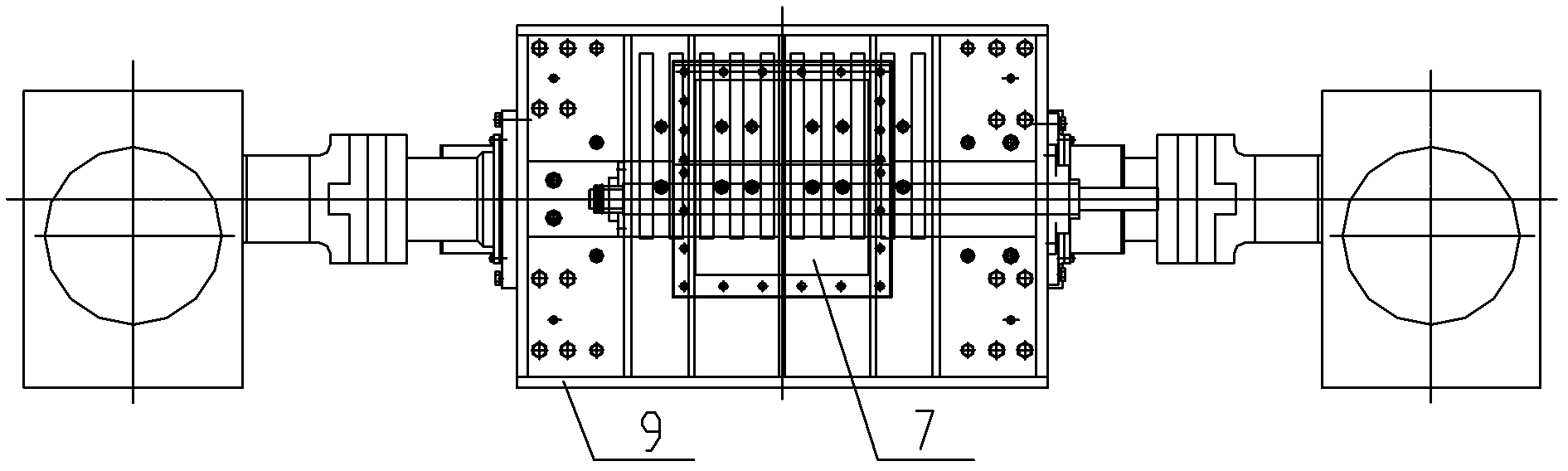

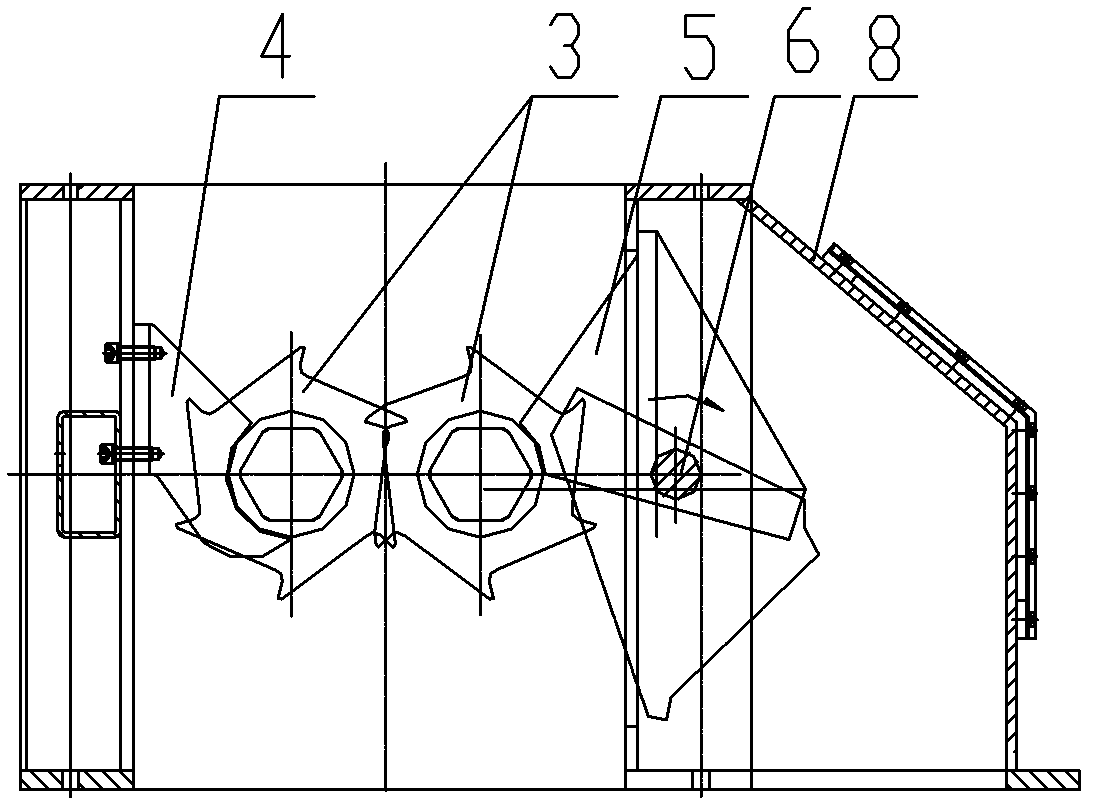

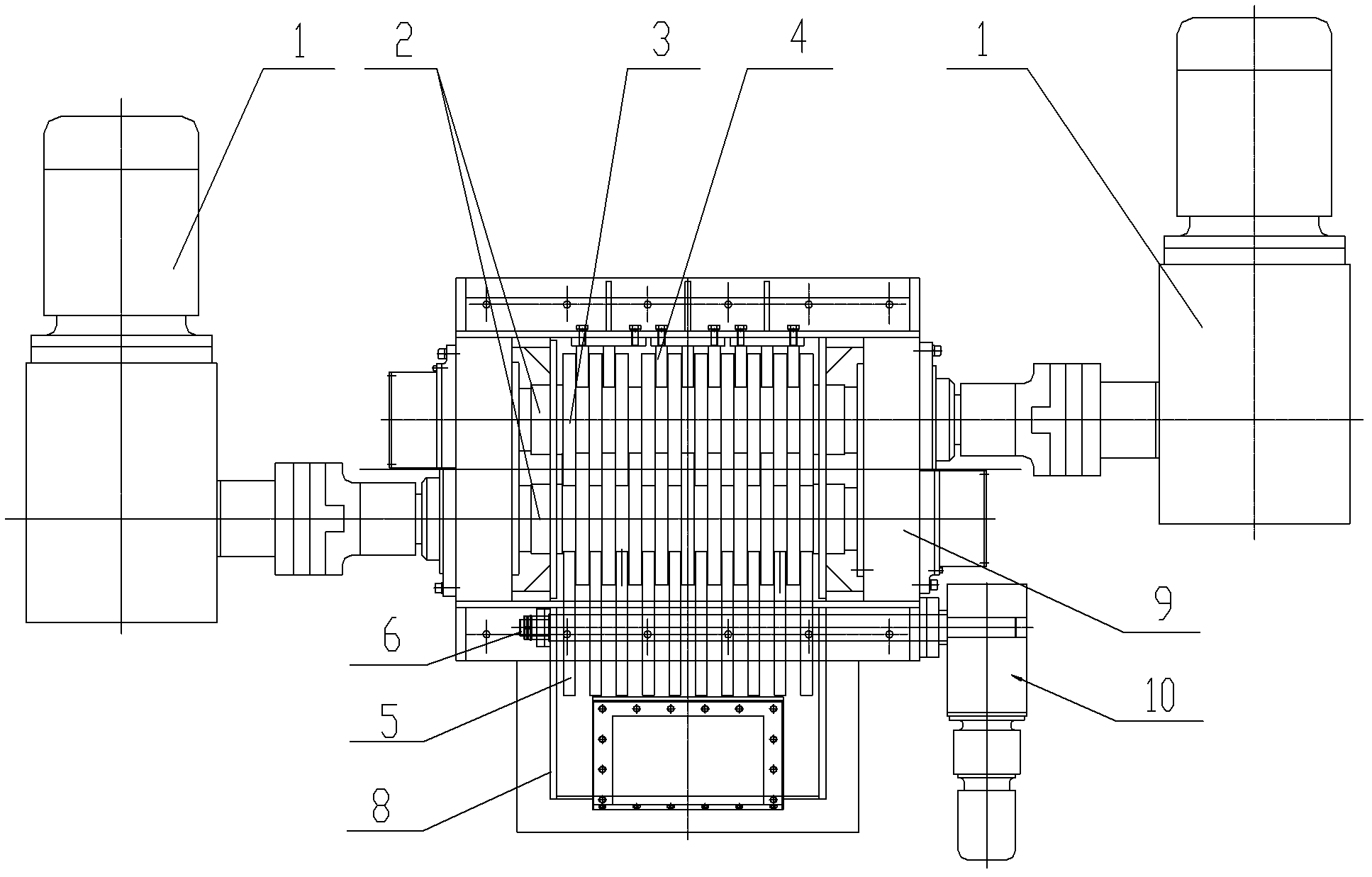

[0012] See Figure 1 ~ Figure 3 , a solid waste crusher, comprising a main box 9 and two mutually parallel main shafts 2 installed in the main box 9, each of the main shafts 2 is equipped with a plurality of crushing knives 3, and the two The center line of the main shaft 2 is in the same horizontal plane, and the two sides of the main box 9 are respectively equipped with a plurality of fixed knives 4, 5 interlaced with a plurality of the crushing knives 3, and each main shaft 2 is connected with a Drive device 1, one side of the main box 9 is provided with a side box 8 communicating with it, the side box is provided with a material outlet 7; the side box 8 is equipped with a rotating shaft 6, and the side box 8 is equipped with a rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com