Evaporative crystallization method and system

An evaporation crystallization and evaporation tank technology, which is applied in the field of solid-liquid separation, can solve the problems of lax valve closure, pipeline and equipment blockage, device shutdown, etc., achieve low energy consumption and operating costs, improve yield and quality, and ensure The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

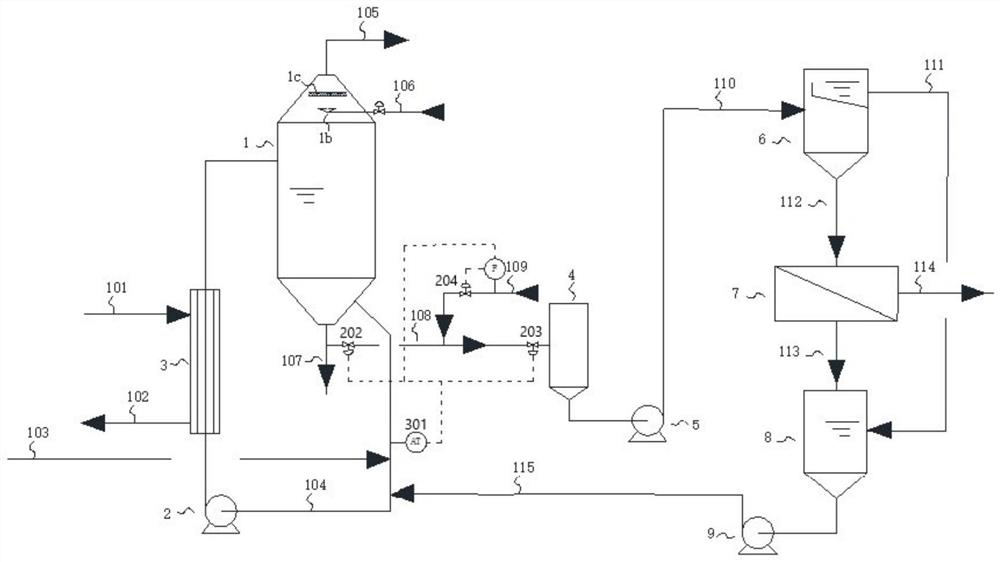

[0068] use as figure 1 In the system shown, NaCl industrial wastewater (feed rate 580t / h, TDS 25000mg / L, COD 230mg / L) is evaporated and crystallized (the operating temperature of the evaporation tank is 130°C, and the operating pressure is 0.115MPaG). specifically:

[0069] The evaporation crystallization system includes an evaporation crystallization unit, a slurry discharge and flushing unit, and a solid-liquid separation unit; the evaporation crystallization unit includes an evaporation tank 1 and a material circulation pipeline 104 provided with a material circulation pump 2 (axial flow pump) and a heating chamber 3; The solid-liquid separation unit comprises a solid-liquid separation device and a mother liquor circulation line 115, such as figure 1 The shown solid-liquid separation device comprises 1# solid-liquid separation device 6 (thickener), 2# solid-liquid separation device 7 (centrifuge), mother liquor tank 8, mother liquor circulation line 115 is provided with mo...

Embodiment 2

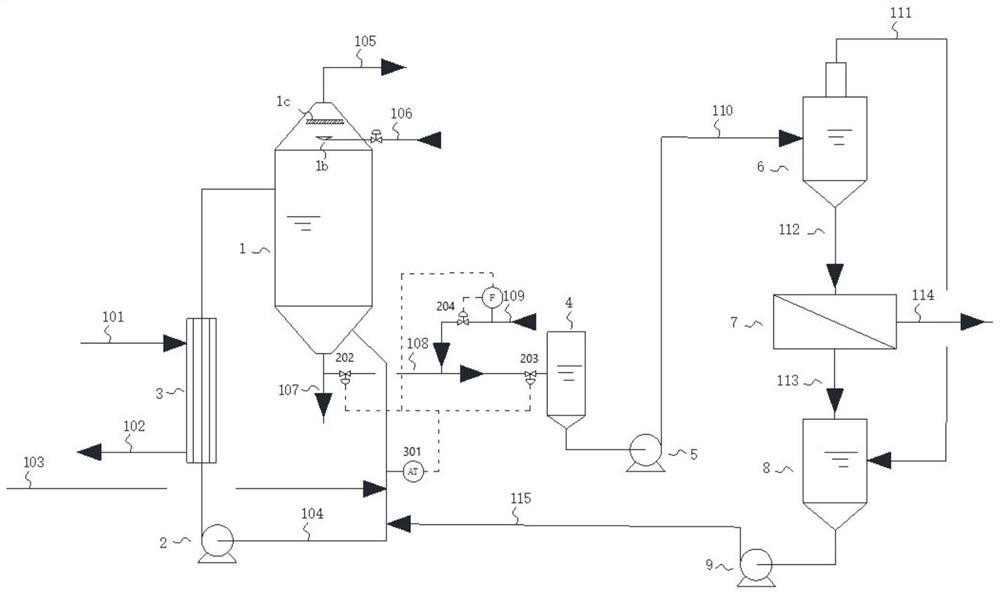

[0079] Adopt the method for embodiment 1 to carry out Na 2 SO 4 Evaporation and crystallization of industrial wastewater, the difference is that the system in this example is figure 2 Shown, 1# solid-liquid separation device 6 is a suspension separator; Na 2 SO 4 The feed rate of industrial wastewater is 300t / h, the TDS is 55000mg / L, and its COD is 500mg / L; the operating temperature of the evaporation tank is 145°C, and the operating pressure is 0.2MPaG; the critical solid-liquid ratio is 25%, which is taken as the upper layer 0.22 times the ratio of the saturated density of concentrated slurry to the density of water.

[0080] Separated Na 2 SO 4 The water content of industrial nitrate crystals is 7.3%, the yield rate is 98%, and the stable operation time of the system exceeds 1000h. Na in the secondary steam condensate at the top of evaporation tank 1 + , SO 4 2- All are less than 100ppmw, COD2 SO 4 Crystalline nitrate, the operating cost is 864 yuan / tNa 2 SO 4 ...

Embodiment 3

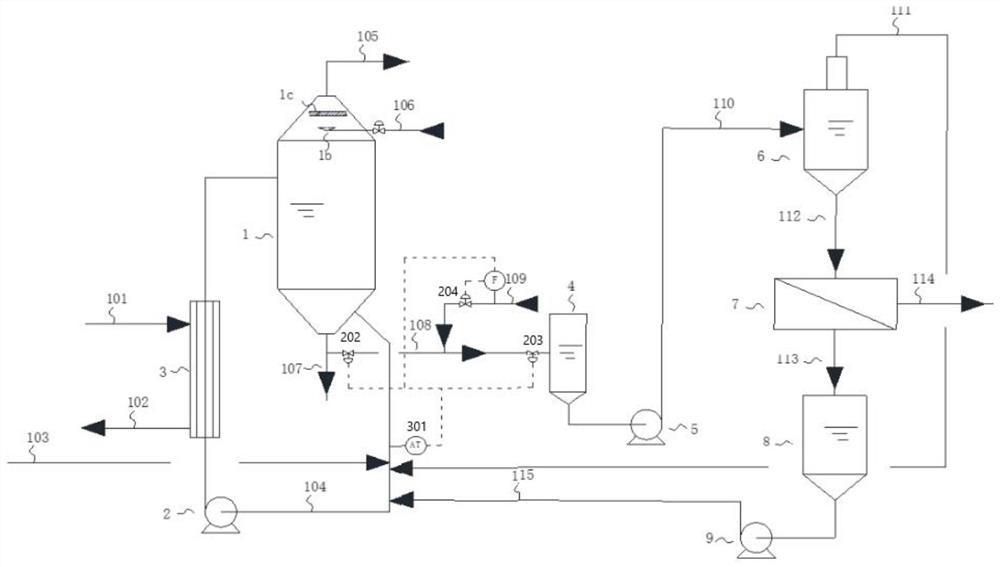

[0082] Adopt the method for embodiment 2 to carry out Na 2 SO 4 Evaporation and crystallization of industrial wastewater, the difference is that the system in this example is image 3 As shown, the saline clear water 111 at the top of the 1# solid-liquid separation device 6 is sent into the material circulation pipeline 104; Na 2 SO 4 The feed rate of industrial wastewater is 350t / h, the TDS is 60000mg / L, and the COD is 750mg / L; the critical solid-liquid ratio is 23%, which is taken as 0.205 times the ratio of the saturated density of the concentrated slurry in the upper layer to the density of water.

[0083] Separated Na 2 SO 4 The water content of industrial nitrate crystals is 5.5%, the yield rate is 97.5%, and the stable operation time of the system exceeds 1050h. Na in the secondary steam condensate at the top of evaporation tank 1 + , SO 4 2- All less than 110ppmw, COD2 SO 4 Crystalline nitrate, the operating cost is 840 yuan / tNa 2 SO 4 Crystalline nitrate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com